Forging Defects

Forging defects are problems that happen while shaping metal during the forging process. These issues can affect how strong or good the final product is. They can be caused by things like bad tool design, poor-quality materials, mistakes in how the metal is shaped, or problems after the forging is done.

Types of Forging Defects

- Laps

- Cracks

- Unfilling

- Scaling

- Mismatch

- Internal Cracks

- Cold Shuts

- Grain Flow Disruption

- Scale Pits

- Improper Grain Growth

- Fold

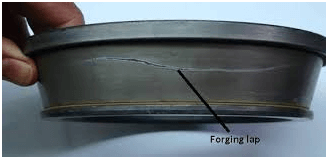

What Are Laps?

What Are Laps?

Laps are surface defects that look like thin lines, seams, or folds on forged metal parts. They appear when the metal folds over itself but doesn’t fully join together, leaving weak spots.

How Do Laps Form?

Laps occur during forging when part of the metal folds instead of flowing smoothly, and the folded areas don’t fuse properly. This results in surface cracks or creases.

Common Causes of Laps:

Too much metal in the die cavity

Poor die design that disrupts smooth metal flow

Low forging temperature, making the metal harder to shape

Uneven or improper hammering or pressing

Why Laps Matter:

They reduce the strength of the part

Laps can turn into cracks during use

They affect the surface finish and overall quality

How to Prevent Laps:

Use the correct amount of metal

Design dies to guide metal flow smoothly

Keep the metal at the right temperature

Apply even, controlled force during forging

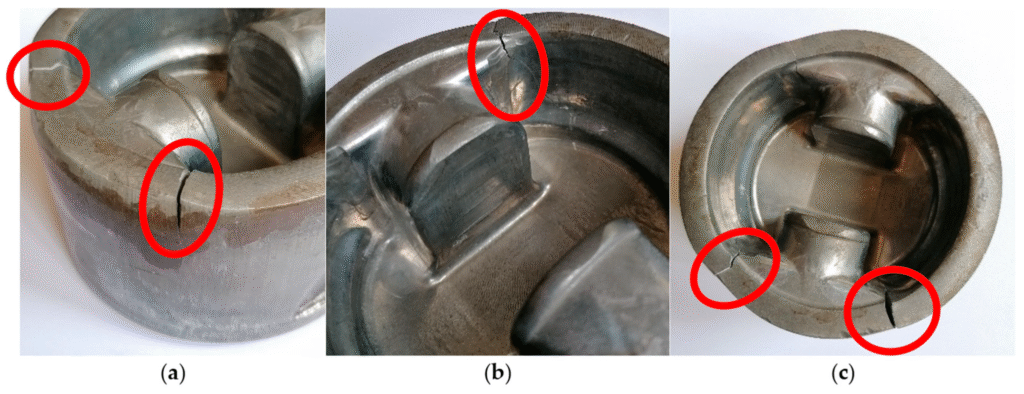

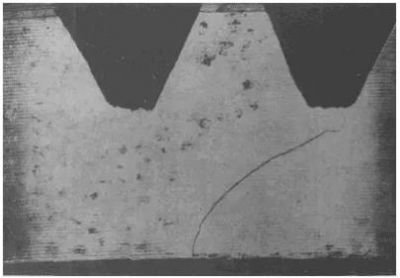

What Are Cracks?

Cracks are splits or fractures that appear in forged metal parts. They can show up on the surface or inside the part and usually form when the metal can’t handle the stress during forging.

How Do Cracks Form?

Cracks happen when the metal is stretched, bent, or compressed too much during forging, especially if it’s too cold or brittle. This causes it to break instead of flow smoothly.

Common Causes of Cracks:

Forging the metal at too low a temperature

Using raw materials with internal flaws

Applying too much force too quickly

Poor die design that creates uneven stress

Improper cooling after forging

Why Cracks Matter:

They can seriously weaken the forged part

Cracks may grow over time, leading to part failure

They affect safety, especially in critical components

Hard to detect if they form inside the part

How to Prevent Cracks:

Heat the metal to the right temperature before forging

Use high-quality, defect-free raw materials

Apply controlled and gradual pressure

Design dies to reduce stress concentrations

Cool the forged part evenly and carefully

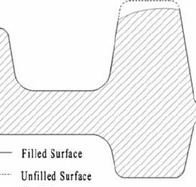

What Is Underfilling?

Underfilling, also known as incomplete filling, is a defect where the metal does not completely fill the die cavity. This results in missing sections, low spots, or incomplete shapes in the forged part.

How Does Underfilling Happen?

Underfilling occurs when there isn’t enough metal flow to fill all areas of the die. This often happens when there’s not enough material, not enough pressure, or the metal isn’t soft enough to flow properly.

Common Causes of Underfilling:

Not enough metal (workpiece is too small)

Low forging pressure or force

Low forging temperature, making the metal harder to shape

Poor die design with hard-to-reach areas

Inadequate lubrication causing friction and flow restriction

Why Underfilling Matters:

Results in incomplete or misshaped parts

Weakens the final product, especially in load-bearing areas

May require rework or lead to scrapping the part

Affects dimensional accuracy and performance

How to Prevent Underfilling:

Use the correct amount of material

Ensure proper and consistent forging pressure

Maintain the right forging temperature

Design dies for smooth and complete metal flow

Use proper lubrication to reduce friction

What Is Scaling?

Scaling is a surface defect where a layer of oxide (rust-like material) forms on the metal during heating. It looks like rough, flaky patches on the surface and can affect the appearance and quality of the forged part.

How Does Scaling Happen?

Scaling occurs when hot metal reacts with oxygen in the air during the heating process. This forms iron oxide (scale), which can stick to the surface and sometimes get pressed into the metal during forging.

Common Causes of Scaling:

Heating metal in open air without protection

High forging temperatures

Long exposure time to heat before forging

Poor furnace control or maintenance

Why Scaling Matters:

Creates an uneven, rough surface

Can reduce the final product’s strength and accuracy

Scale particles may get embedded in the metal, causing surface defects

May require extra cleaning or machining

How to Prevent Scaling:

Use protective atmospheres or coatings when heating metal

Minimize the time metal is exposed to high temperatures

Keep forging temperatures within recommended limits

Clean the workpiece surface before forging if scale forms

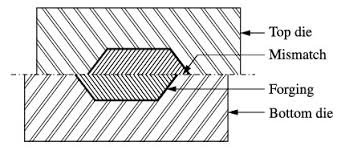

What Is Mismatch?

Mismatch is a defect where the upper and lower parts of the forged piece do not line up correctly. This causes a step or offset along the joint, making the part look uneven or misaligned.

How Does Mismatch Happen?

Mismatch happens when the top and bottom dies are not properly aligned during forging. As a result, the metal flows unevenly and creates a visible shift between the two halves of the part.

Common Causes of Mismatch:

Poor alignment of upper and lower dies

Worn-out or damaged die holders or guide systems

Loose tooling setup

Inaccurate positioning of the workpiece in the die

Why Mismatch Matters:

Affects the part’s dimensional accuracy

Can weaken the part, especially if it’s used in precision applications

May require rework or machining to correct

Reduces the overall quality and appearance of the product

How to Prevent Mismatch:

Regularly check and align dies before forging

Maintain and replace worn tooling components

Use accurate die holders and guiding systems

Secure the workpiece properly before forging

What Are Internal Cracks?

Internal cracks are hidden fractures that form inside the forged part. Unlike surface cracks, they are not visible from the outside but can seriously affect the strength and performance of the part.

How Do Internal Cracks Form?

Internal cracks develop when the metal experiences too much stress or uneven flow during forging. If the metal is not ductile enough or the force is applied too quickly, it can tear inside without showing on the surface.

Common Causes of Internal Cracks:

Forging at very high temperatures

Excessive or uneven deformation

Poor-quality raw material with internal flaws

Incorrect forging speed or pressure

Improper die design causing stress concentration

Why Internal Cracks Matter:

They weaken the part from the inside

Cracks can grow during use, leading to sudden failure

Hard to detect without special testing (e.g. ultrasonic testing)

Unsafe for critical applications like automotive or aerospace parts

How to Prevent Internal Cracks:

Control forging temperature and avoid overheating

Apply deformation gradually and evenly

Use high-quality, defect-free raw materials

Design dies to ensure uniform metal flow

Use non-destructive testing (NDT) to check for hidden flaws

What Are Cold Shuts?

Cold shuts are surface defects that look like thin lines or seams where two metal flows meet but don’t properly join. They create weak spots that can lead to cracking or failure.

How Do Cold Shuts Form?

Cold shuts happen when two streams of metal come together during forging but don’t fuse properly. This usually occurs when the metal is too cold or when the die design doesn’t allow smooth, continuous flow.

Common Causes of Cold Shuts:

Low forging temperature, causing poor metal bonding

Poor die design that splits and misguides the metal flow

Slow or uneven metal flow during forging

Oxide layers between metal flows preventing fusion

Why Cold Shuts Matter:

Act as cracks and weaken the part

May cause failure under stress or fatigue

Reduce the quality and appearance of the forged piece

Often require rework or lead to part rejection

How to Prevent Cold Shuts:

Maintain the proper forging temperature

Design dies to ensure smooth and continuous metal flow

Use steady, controlled forging pressure

Clean the billet surface to avoid oxide buildup

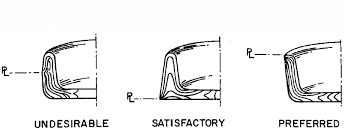

What Are Grain Flow Disruption?

Grain flow disruption is a defect where the internal grain structure of the metal is misaligned or irregular. This weakens the part because the grains don’t follow the natural shape or direction of the forged piece.

How Does Grain Flow Disruption Happen?

During forging, the metal’s grains should flow in the direction of the part’s shape. Disruption occurs when the forging process doesn’t control this flow properly, causing the grains to bend, twist, or misalign.

Common Causes of Grain Flow Disruption:

Incorrect forging technique or direction

Poor die design that doesn’t guide the metal flow properly

Using preforms or billets that aren’t suited for the final shape

Inadequate deformation or uneven metal flow

Why Grain Flow Disruption Matters:

Reduces strength and durability, especially under stress

Makes the part more likely to crack or fail

Can lead to inconsistent performance

Affects fatigue resistance and toughness

How to Prevent Grain Flow Disruption:

Design the forging process to control and align grain flow with the final shape

Use proper die design that promotes smooth metal deformation

Choose appropriate raw material shapes (billets or preforms)

Apply forging pressure and direction correctly

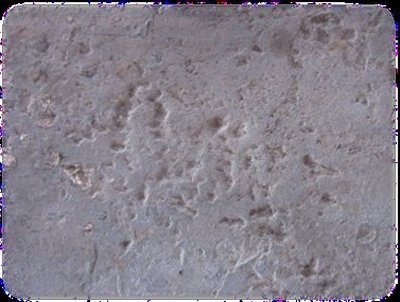

What Are Scale Pits?

Scale pits are small holes or depressions on the surface of a forged part. They are caused by pieces of scale (oxidized metal) that get pressed into the surface during forging and later fall out, leaving pits behind.

How Do Scale Pits Form?

When metal is heated for forging, it forms a layer of oxide (called scale) on the surface. If this scale is not cleaned off before forging, it can get embedded into the part and create pits when it breaks away.

Common Causes of Scale Pits:

Forging metal with loose or thick scale on the surface

Not cleaning the billet before forging

Heating metal too high or for too long

Poor furnace maintenance or control

Why Scale Pits Matter:

Damage the surface finish of the part

Can reduce fatigue strength and durability

May require additional machining or surface treatment

Affect the appearance and quality of the final product

How to Prevent Scale Pits:

Clean the billet surface before forging (e.g. brushing or shot blasting)

Avoid overheating and limit time in the furnace

Use protective coatings or atmospheres during heating

Maintain furnaces properly to control oxidation

What Is Improper Grain Growth?

Improper grain growth is a defect where the metal’s internal grain structure becomes too large or uneven. This can weaken the part and reduce its toughness and fatigue resistance.

How Does Improper Grain Growth Happen?

Grains grow when the metal is held at high temperatures for too long. If the forging process isn’t well controlled, the grains can become too large or grow in the wrong way, reducing the mechanical strength of the part.

Common Causes of Improper Grain Growth:

Holding the metal at high temperatures for too long

Reheating the metal multiple times

Poor control of forging temperature and time

Slow cooling after forging

Why Improper Grain Growth Matters:

Reduces strength, toughness, and fatigue life

Makes the part more brittle and likely to crack

Leads to poor performance in high-stress applications

Can affect surface finish and internal quality

How to Prevent Improper Grain Growth:

Use correct forging temperatures and avoid overheating

Limit the time metal is kept hot

Avoid unnecessary reheating of the workpiece

Control the cooling rate after forging (not too slow)

What Are Folds?

Folds are surface defects that look like lines or ridges where the metal has bent over itself but hasn’t fused properly. They appear like overlapping layers and can be mistaken for cracks or seams.

How Do Folds Form?

Folds occur when excess metal is squeezed out of the die cavity and gets pushed back into the part without bonding properly. This usually happens when the metal flow is not smooth or controlled.

Common Causes of Folds:

Excess material in the die cavity

Improper or worn die design

Incorrect metal flow during forging

Low forging temperature, making the metal less ductile

Why Folds Matter:

Create weak points that can crack under stress

Reduce surface quality and appearance

Can trap contaminants and cause corrosion

May lead to part rejection or require rework

How to Prevent Folds:

Use the correct amount of material

Maintain and properly design forging dies

Ensure smooth, even metal flow during forging

Keep the forging temperature within the recommended range