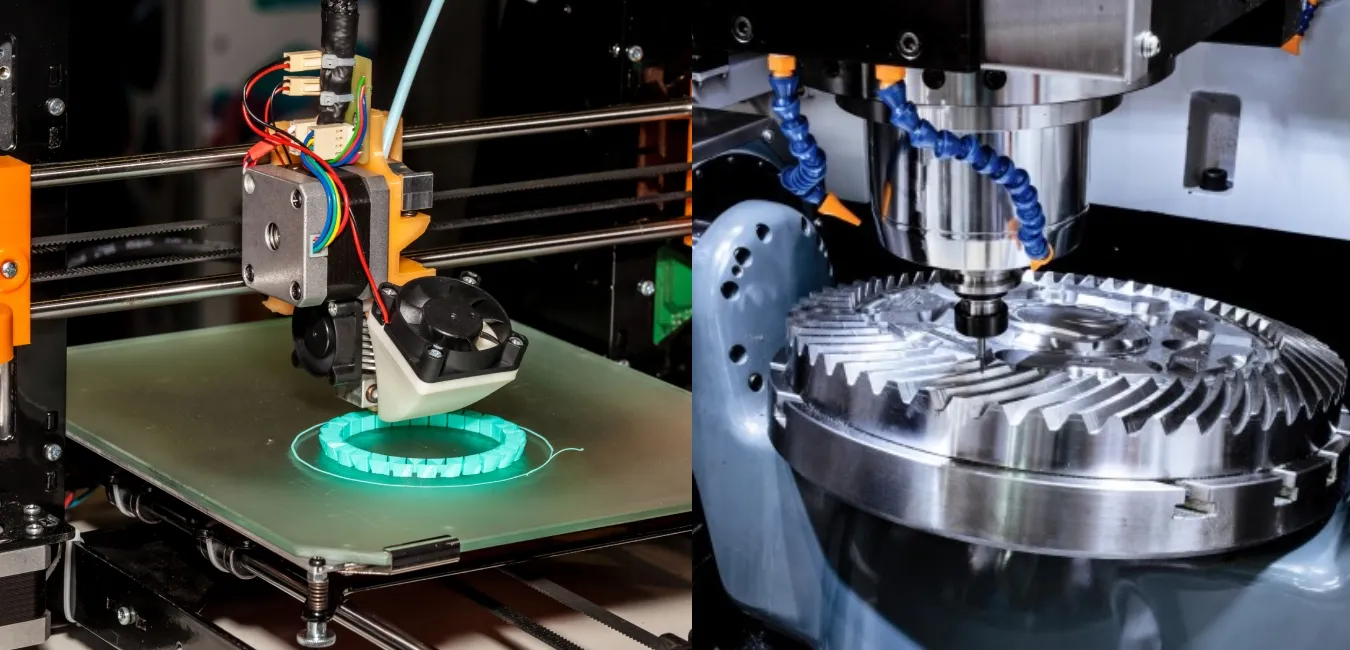

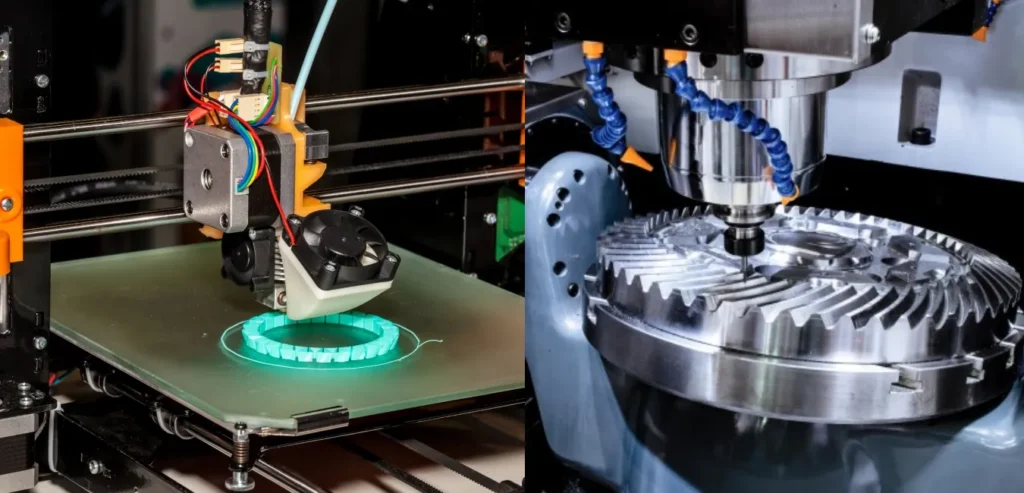

Difference between 3D Printing vs Machining

Feature | Machining | Additive Manufacturing (3D Printing) |

|---|---|---|

| Process Type | Subtractive | Additive |

| Material Usage | Material is removed from a solid block (e.g., CNC milling, turning) | Material is added layer by layer to build a part |

| Material Waste | Higher – excess material is cut away | Lower – material is only used where needed |

| Typical Materials | Metals, plastics, composites (in solid form) | Thermoplastics, resins, metals (in powder or filament form) |

| Tooling | Requires cutting tools and fixtures | Requires minimal tooling (mostly just the printer and support structures) |

| Surface Finish | Usually better surface finish and tighter tolerances | Often rougher surfaces; may require post-processing |

| Speed | Faster for single, simple parts; slower for complex geometries | Slower for large or simple parts; faster for complex or custom shapes |

| Complexity | Complex shapes can be difficult or expensive to machine | Easily handles complex geometries, internal features, and custom designs |

| Cost for Prototypes | Higher initial setup cost | Lower cost and quicker turnaround for prototypes |

| Batch Size Efficiency | More efficient for large-volume production | Best suited for small batches or one-off parts |

| Common Applications | Aerospace, automotive, industrial parts | Prototyping, biomedical, aerospace, custom tooling |

Introduction to 3D Printing

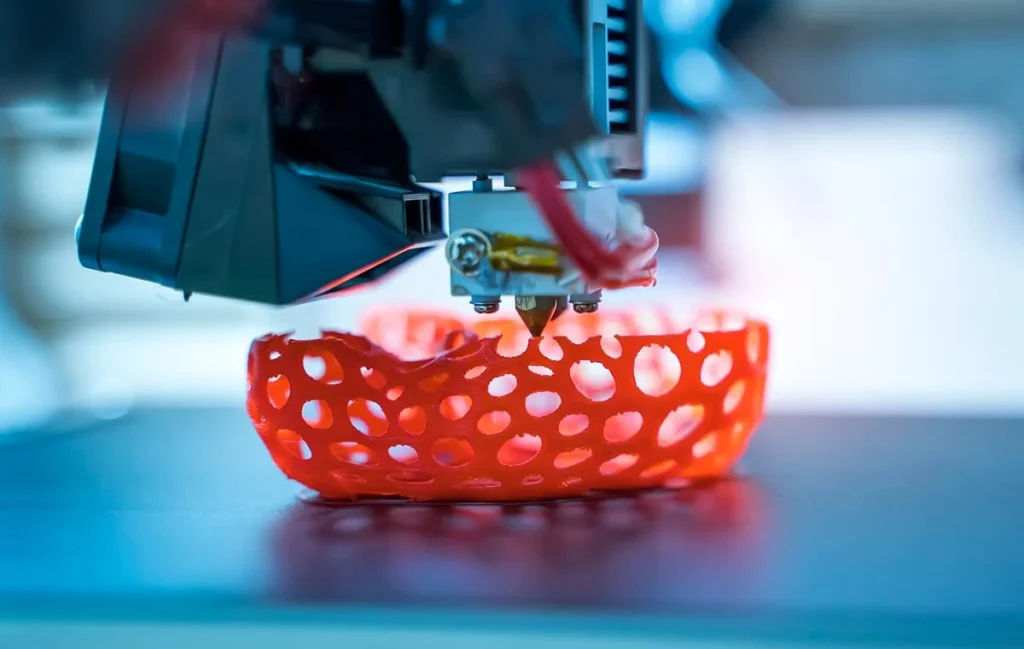

3D printing, also known as additive manufacturing, is a revolutionary technology that creates three-dimensional objects from a digital design by layering materials precisely one on top of another. Unlike traditional subtractive manufacturing methods, where material is removed to create a product, 3D printing builds objects layer-by-layer, allowing for complex shapes and geometries that were previously difficult or impossible to achieve.

This technology transforms digital 3D models into physical objects using materials such as plastics, metals, resins, and even ceramics. The rise of 3D printing has dramatically impacted various industries by accelerating prototyping, reducing manufacturing costs, and enabling customization at scale.

Types of 3D Printing Technologies

There are several types of 3D printing technologies, each with unique processes, materials, and applications. The main types include:

1. Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF)

FDM is the most widely used and affordable 3D printing method. It works by heating and extruding thermoplastic filament through a nozzle, which deposits the material layer-by-layer on a build platform. Common materials include PLA, ABS, and PETG.

Advantages: Simple, cost-effective, and accessible for hobbyists and professionals.

Applications: Prototyping, household items, educational models.

2. Stereolithography (SLA)

SLA uses a laser to cure liquid resin in a vat layer-by-layer, solidifying the resin to form the object. It is known for producing high-resolution, smooth-surfaced parts.

Advantages: High precision and fine detail, smooth finishes.

Applications: Dental models, jewelry, intricate prototypes.

3. Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered material, typically nylon or other polymers, by sintering the particles together. The powder bed supports the object during printing, eliminating the need for support structures.

Advantages: Durable parts, complex geometries, no support structures.

Applications: Functional prototypes, aerospace, automotive parts.

4. Digital Light Processing (DLP)

Similar to SLA, DLP uses a digital projector screen to flash each layer onto the resin surface, curing it all at once. This method is faster than SLA while maintaining high detail.

Advantages: Fast printing, high resolution.

Applications: Dental, jewelry, small detailed parts.

5. Binder Jetting

This process sprays a liquid binding agent onto a powder bed to selectively bond powder particles layer-by-layer. It can use various materials including metals, sand, and ceramics.

Advantages: Full-color printing possible, scalable.

Applications: Sand casting molds, full-color prototypes.

6. Material Jetting

Material jetting deposits droplets of photopolymer onto the build platform and cures them with UV light. It can print multiple materials and colors simultaneously.

Advantages: Smooth surfaces, multi-material prints.

Applications: Medical models, prototypes with varying properties.

7. Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM)

Both techniques use a high-powered laser to fully melt or sinter metal powder, creating solid metal parts.

Advantages: Strong metal parts, complex metal components.

Applications: Aerospace, medical implants, automotive.

Applications of 3D Printing

3D printing has found applications across a wide range of industries, transforming product development and manufacturing:

1. Aerospace

The aerospace industry benefits from lightweight, complex components that reduce fuel consumption. 3D printing is used for prototyping, tooling, and manufacturing end-use parts like engine components and brackets.

2. Automotive

Automakers use 3D printing for rapid prototyping, tooling, and even manufacturing custom parts. It helps reduce lead times in design cycles and supports low-volume production of specialty parts.

3. Healthcare and Medical

3D printing enables patient-specific implants, prosthetics, and surgical guides tailored to individual anatomy. It also allows rapid prototyping of medical devices and the creation of biocompatible implants.

4. Dentistry

Dental labs use 3D printing to produce crowns, bridges, aligners, and surgical models with high accuracy and speed, improving patient outcomes and reducing turnaround times.

5. Consumer Products and Fashion

Custom footwear, eyewear, jewelry, and clothing benefit from 3D printing’s customization and rapid prototyping. Designers can experiment with novel forms and materials.

6. Education and Research

3D printing serves as a teaching tool for design, engineering, and science. It helps students and researchers quickly bring ideas to life and conduct hands-on experiments.

7. Architecture and Construction

Architects use 3D printing to create detailed scale models of buildings. Construction companies are exploring large-scale 3D printing to build houses and structural components.

8. Food Industry

3D printing in food allows for the creation of customized shapes and textures, using edible materials like chocolate or dough, offering new culinary experiences.

9. Art and Cultural Heritage

Artists and museums use 3D printing to create sculptures, replicas, and restoration pieces, preserving cultural heritage and enabling new artistic expressions.

Benefits of 3D Printing

3D printing offers numerous advantages that have disrupted traditional manufacturing methods:

1. Rapid Prototyping

3D printing accelerates the design cycle by enabling quick creation of prototypes. Designers can test form, fit, and function rapidly, reducing the time between iterations from weeks or months to days or hours.

2. Customization and Personalization

Since 3D printing uses digital files, it allows for easy customization. Products can be tailored to individual specifications without requiring retooling, ideal for custom medical implants, fashion, and consumer goods.

3. Complex Geometries

Additive manufacturing can create intricate and complex designs that are difficult or impossible with traditional manufacturing—like internal channels, lattice structures, or organic shapes.

4. Reduced Waste

Because material is added layer-by-layer, 3D printing typically produces less waste compared to subtractive processes, where excess material is cut away.

5. On-Demand Production

3D printing enables on-demand manufacturing, reducing the need for large inventories and storage costs. This is beneficial for spare parts and low-volume production.

6. Cost-Effective for Low Volumes

For small production runs, 3D printing can be more economical than traditional tooling and molding, which require expensive molds and setups.

Limitations of 3D Printing

Despite its benefits, 3D printing has several limitations to consider:

1. Material Limitations

While the variety of printable materials is growing, it is still limited compared to conventional manufacturing. Not all materials can be 3D printed, and printable materials may not always match the mechanical properties of traditionally manufactured parts.

2. Surface Finish and Accuracy

Some 3D printing methods produce parts with rough surfaces or visible layer lines that require post-processing for a smooth finish. Also, dimensional accuracy can be lower than precision machining.

3. Build Size Constraints

Most 3D printers have limited build volumes, restricting the maximum size of printable parts. Large objects may need to be printed in sections and assembled.

4. Printing Speed

3D printing can be slower than mass production techniques like injection molding for large volumes. Printing large or highly detailed parts can take many hours or days.

5. Cost for High-Volume Production

While 3D printing is cost-effective for prototyping and small runs, for large-scale production traditional manufacturing is typically more economical due to economies of scale.

6. Mechanical Strength and Durability

Additive parts may have anisotropic mechanical properties, meaning strength varies depending on the printing direction. This can limit their use in high-stress applications without further treatment.

Introduction to Machining

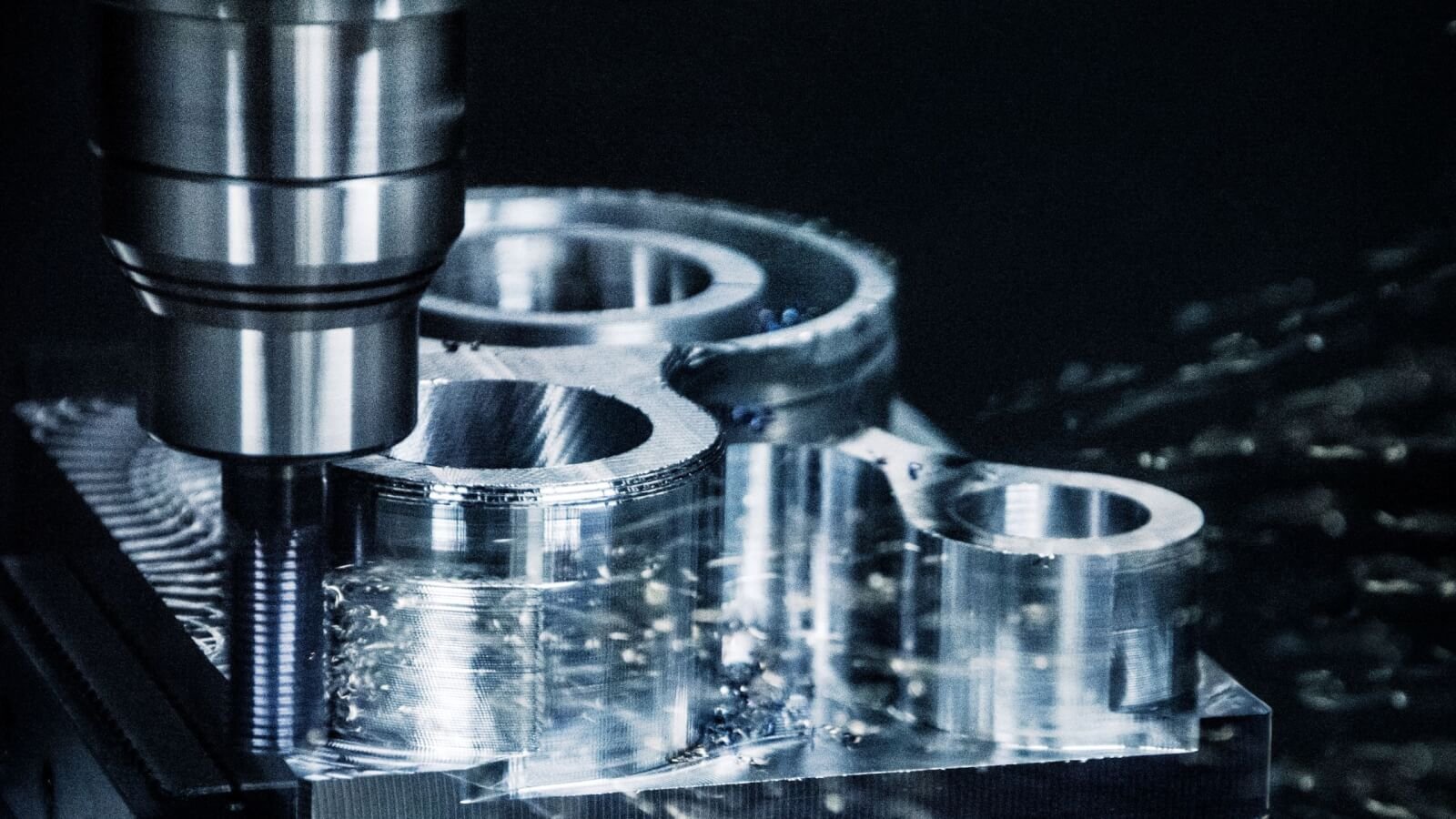

Machining is a traditional manufacturing process that involves removing material from a raw workpiece to create a desired shape or form. It is a subtractive manufacturing technique where material is cut, drilled, milled, or ground away using various tools and machines, either manually or through advanced computer numerical control (CNC) systems. Unlike additive manufacturing (such as 3D printing), machining shapes parts by physically removing excess material from solid workpieces like metals, plastics, and composites to achieve high precision and tight tolerances.

Machining has been fundamental to industrial production for over a century and remains a cornerstone in producing accurate, durable, and complex components used in almost every industry today. It is especially vital for applications requiring high-performance parts with specific mechanical properties, smooth finishes, and reliable dimensional consistency—such as aerospace, automotive, energy, and medical device manufacturing. The versatility of machining allows manufacturers to work with a wide range of materials and geometries, from simple components to intricate designs.

Thanks to continuous advancements in tooling, software, and automation technologies, machining continues to evolve as a highly reliable, efficient, and scalable manufacturing solution, supporting everything from prototyping to high-volume production.

Types of Machining Processes

Machining processes can be broadly classified based on the method of material removal. The most common types include:

1. Turning

Turning involves rotating the workpiece on a lathe while a cutting tool moves linearly to remove material. It’s used to create cylindrical parts such as shafts, rods, and bushings.

Example tools: Lathe machines.

Materials: Metals, plastics.

Applications: Automotive parts, screws, pulleys.

2. Milling

Milling removes material by advancing a rotating cutting tool into a stationary workpiece. It can create flat surfaces, slots, holes, and complex 3D shapes.

Example tools: Vertical and horizontal milling machines, CNC milling centers.

Materials: Metals, plastics, composites.

Applications: Engine blocks, molds, aerospace components.

3. Drilling

Drilling uses a rotating drill bit to cut circular holes into the workpiece.

Example tools: Drill presses, CNC drilling machines.

Materials: Metals, plastics, wood.

Applications: Holes for fasteners, fluid passages.

4. Grinding

Grinding uses an abrasive wheel to remove small amounts of material and produce fine finishes or precise dimensions.

Example tools: Surface grinders, cylindrical grinders.

Materials: Hard metals, tool steels.

Applications: Precision parts, molds, cutting tools.

5. Boring

Boring enlarges an existing hole with a single-point cutting tool to achieve greater accuracy in diameter and finish.

Example tools: Boring mills, CNC boring machines.

Materials: Metals, plastics.

Applications: Engine cylinders, valve bodies.

6. Electrical Discharge Machining (EDM)

EDM removes material by electrical sparks between an electrode and the workpiece submerged in a dielectric fluid. It can cut complex shapes in hard materials without mechanical forces.

Example tools: EDM machines (wire-cut and sinker EDM).

Materials: Hard metals, tool steels, carbides.

Applications: Dies, molds, intricate components.

7. Other Specialized Processes

Broaching: Removes material with a toothed tool to create precise shapes.

Planing and Shaping: Produces flat or contoured surfaces by linear tool movement.

Benefits of Machining

Machining offers several key advantages that make it vital for modern manufacturing:

1. High Precision and Accuracy

Machining can achieve very tight tolerances, often down to microns, making it suitable for critical components where precision is essential.

2. Versatility of Materials

Machining works with a broad range of materials, including metals (steel, aluminum, titanium), plastics, composites, and ceramics, enabling its use across many industries.

3. Surface Finish Quality

Processes like grinding and fine milling produce excellent surface finishes required for parts that must mate or seal precisely.

4. Complex Geometries and Features

CNC machining can produce complex shapes, holes, threads, slots, and intricate patterns that may be difficult or impossible with casting or forging alone.

5. Scalability

Machining supports both one-off prototypes and large-scale production runs, offering flexibility in manufacturing volume.

6. Established Technology and Infrastructure

Machining is a mature industry with well-developed equipment, software, and skilled labor readily available worldwide.

Limitations of Machining

Despite its strengths, machining also has limitations that influence when and how it is used:

1. Material Waste

Since machining removes material from a solid block, it generates considerable scrap compared to additive manufacturing methods.

2. Tool Wear and Costs

Cutting tools wear down and require frequent replacement, which adds to operating costs. Tool life depends on the material being machined and cutting conditions.

3. Time-Consuming for Complex Parts

Complex parts with intricate features may require multiple setups and tools, increasing machining time and cost.

4. Limited to Subtractive Geometry

Machining cannot produce internal cavities or complex internal geometries that are not accessible by cutting tools.

5. High Setup Costs for Small Runs

Setting up CNC machines, programming, and fixturing can be costly, especially for small batch sizes.

6. Energy and Environmental Considerations

Machining often requires coolants, lubricants, and electricity, generating waste fluids and energy consumption concerns.

Applications of Machining

Machining is integral to manufacturing a wide array of products and components across diverse industries:

1. Aerospace Industry

Aerospace components require high precision, tight tolerances, and complex geometries. Machining is used for engine parts, structural components, landing gear, and turbine blades.

2. Automotive Industry

From engine blocks and transmission parts to custom performance components, machining produces parts with durability and precision.

3. Medical Devices

Machining produces surgical instruments, orthopedic implants, dental tools, and custom prosthetics with exact specifications.

4. Electronics and Semiconductor Industry

Machining is used for heat sinks, enclosures, precision connectors, and molds for semiconductor manufacturing.

5. Tool and Die Making

Molds, dies, and tooling components require extremely tight tolerances and fine finishes, often produced by precision machining.

6. Energy Sector

Machined parts are essential in oil & gas, power generation, and renewable energy, including turbine components and valves.

7. Industrial Machinery

Components such as gears, shafts, and housings for industrial machines are produced through machining.

8. Consumer Products

Machining helps produce metal components in appliances, sporting goods, and luxury items.

Machining in Modern Manufacturing

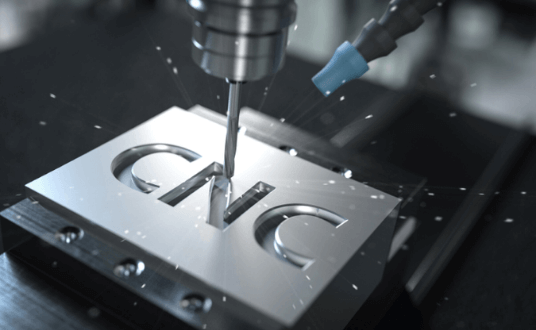

CNC Machining

Computer Numerical Control (CNC) machining has revolutionized machining by automating tool movement through computer programming. CNC machines can precisely control complex tool paths and produce consistent, repeatable parts with minimal operator intervention. This has increased productivity, reduced errors, and enabled the manufacture of intricate parts that would be difficult manually.

Hybrid Manufacturing

In some advanced scenarios, machining is combined with additive manufacturing to create near-net-shape parts that are then finished with machining for precision. This hybrid approach leverages the strengths of both processes.

Conclusion

3D printing and machining represent two complementary pillars of modern manufacturing, each with unique strengths and limitations. 3D printing, as an additive process, excels in rapid prototyping, customization, and producing complex geometries with minimal waste. It opens new possibilities in industries like aerospace, healthcare, and consumer goods by enabling flexible, on-demand production. However, it still faces challenges related to material diversity, build size, and production speed.

On the other hand, machining remains a critical subtractive method prized for its precision, surface finish quality, and versatility across a broad range of materials. It is well-suited for producing durable, high-tolerance parts essential in automotive, aerospace, medical, and industrial sectors. Innovations such as CNC and hybrid manufacturing have improved its efficiency and expanded its capabilities.

Together, these technologies offer manufacturers a powerful toolkit: 3D printing for innovation and customization, and machining for precision and strength. As both fields continue to evolve and integrate with digital manufacturing systems, they will drive more efficient, sustainable, and innovative production processes, shaping the future of manufacturing across diverse industries.

Related posts:

- CNC Machining: 5 Powerful Benefits, How It Works, and Key Applications

- 5-Axis Machining vs 3-Axis Machining – Essential Differences, Applications & Limitations

- Machining and Types of Machining.

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses