Introduction

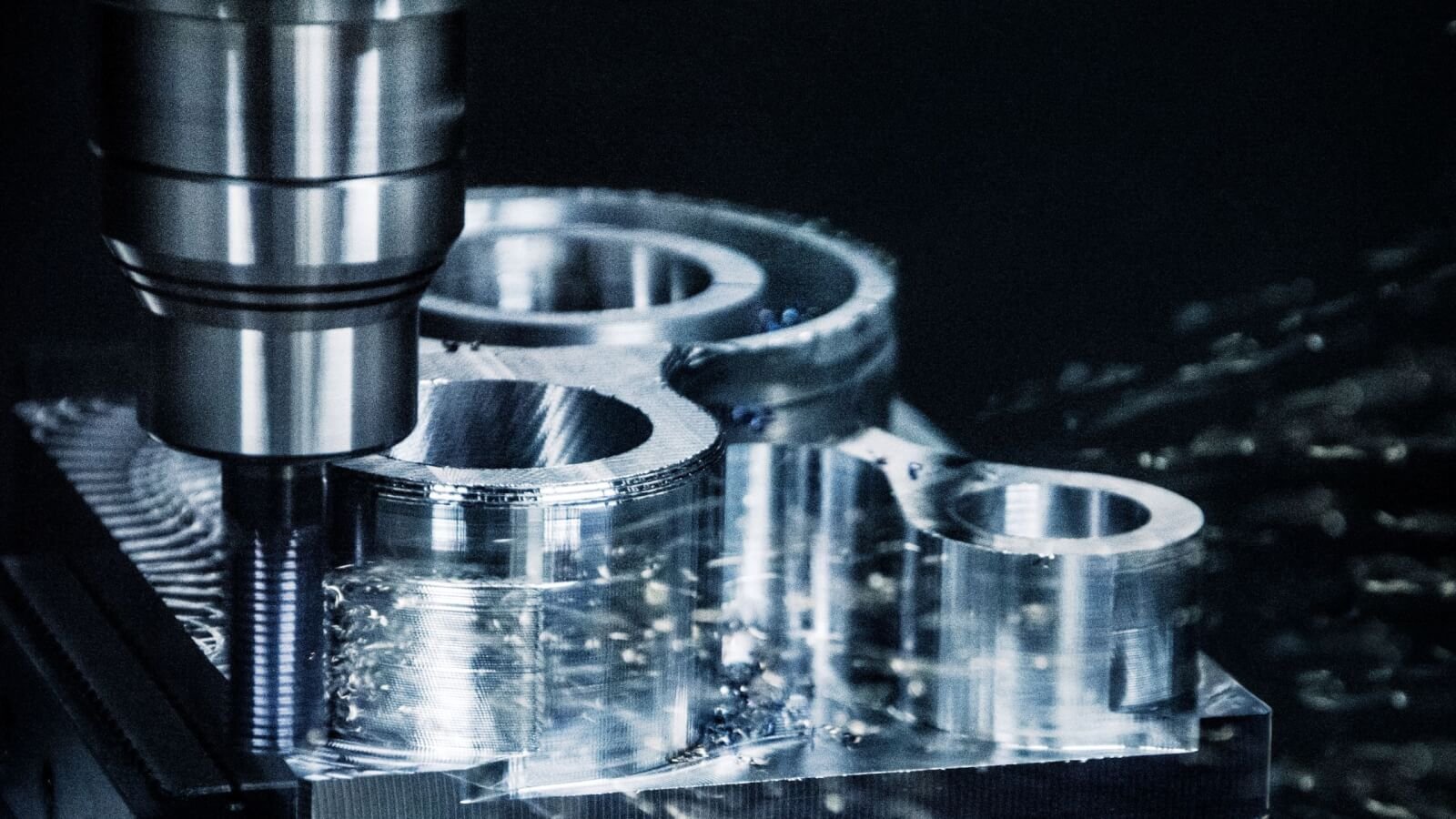

5-axis machining vs 3-axis machining is a crucial comparison in modern manufacturing, especially when precision and efficiency are priorities. Machining technology is essential for producing precise components in many industries. CNC machining includes different methods, with 3-axis and 5-axis machining being two key types. Both use cutting tools to shape materials by removing excess parts. However, they vary greatly in complexity and capabilities. The 3-axis method moves tools along three directions, suitable for simpler shapes. In contrast, 5-axis machining offers more flexibility, allowing movement along five directions for intricate and complex designs. These differences make each method ideal for specific applications depending on the precision and complexity required in manufacturing.

What is 3-Axis Machining?

3-axis machining refers to the CNC process where the cutting tool moves along three linear axes:

X-axis: left to right

Y-axis: front to back

Z-axis: up and down (vertical movement)

In this method, the workpiece remains stationary, and the tool moves along these three axes to remove material. The cutting tool’s orientation remains fixed, meaning it does not tilt or rotate. 3-axis machining is ideal for parts with relatively simple geometries such as prismatic shapes, flat surfaces, and pockets.

What is 5-Axis Machining?

5-axis machining extends the capabilities of 3-axis machining by adding two additional rotational axes to the linear X, Y, and Z movements. These two additional axes allow the cutting tool or the workpiece to rotate, providing the tool access to the part from multiple directions.

Rotational axes (A, B, or C): The tool or the workpiece can rotate about one or two axes, typically around the X, Y, or Z axes, respectively.

This increased flexibility enables machining of complex shapes, undercuts, and intricate 3D geometries in fewer setups, often in a single operation.

Machining Process

3-Axis Machining Process

In 3-axis machining:

The cutting tool moves only in linear X, Y, and Z directions.

The orientation of the tool remains constant, typically perpendicular to the work surface.

The operator or CAM programmer defines tool paths that guide the tool along these axes.

Because the tool can’t tilt or rotate, machining complex angled features requires multiple setups where the workpiece is repositioned manually.

Examples of tool movements include contouring, drilling, pocketing, and simple surface milling.

Programming and operation:

Programming 3-axis machining tends to be less complex.

CAM software calculates tool paths based on 2.5D or 3D models but without tool tilting.

Setup involves securing the workpiece, defining the zero point, and running the program.

5-Axis Machining Process

In 5-axis machining:

The tool moves linearly along X, Y, and Z axes.

Simultaneously, it rotates about two additional axes (A, B, or C).

These rotations allow the tool to approach the workpiece from virtually any angle.

Complex surfaces and contours can be machined in a single setup, significantly reducing the need to reposition the workpiece.

The process requires advanced CAM programming to control both linear and rotational movements precisely.

Tool paths must account for tool orientation, collision avoidance, and efficient machining strategies.

Programming and operation:

- More complex than 3-axis programming.

- Requires software capable of simulating multi-axis movements and avoiding collisions.

- Operators must be highly skilled in machine setup and interpretation of CAM data.

Advantages

Advantages of 3-Axis Machining

Simplicity: The process is straightforward with simpler machine tools and programming.

Cost-effective: 3-axis machines tend to be less expensive to purchase and maintain.

Ease of programming: CAM programming and setup are faster and less demanding.

Good for simple parts: Ideal for components with flat or slightly contoured surfaces.

Widely available: Most machine shops have 3-axis capabilities.

Advantages of 5-Axis Machining

- Complex geometry capability: Can machine intricate shapes, undercuts, and 3D surfaces that are impossible or impractical on 3-axis machines.

- Single setup machining: Reduces the number of setups, improving accuracy and repeatability.

- Improved surface finish: Tool orientation can be optimized for better cutting conditions, reducing tool marks and improving finish.

- Reduced cycle times: By machining multiple features in one setup and using optimized tool angles.

- Better tool life: Proper tool orientation reduces cutting forces and wear.

- Enhanced accuracy: Fewer setups mean less risk of misalignment and dimensional errors.

Limitations

Limitations of 3-Axis Machining

Limited complexity: Unable to machine parts with complex contours, undercuts, or angled features in a single setup.

Multiple setups required: Increases machining time, labor cost, and risk of inaccuracies due to repositioning.

Tool orientation fixed: May lead to suboptimal cutting conditions and tool wear.

Surface finish limitations: Difficult to achieve high-quality finishes on complex 3D surfaces.

Limitations of 5-Axis Machining

High cost: Machines and software are significantly more expensive.

Programming complexity: Requires advanced CAM software and highly skilled programmers.

Maintenance: More moving parts and complexity lead to higher maintenance requirements.

Setup difficulty: Machine setup and calibration are more challenging.

Collision risk: Increased risk of collisions between tool, holder, and workpiece, requiring careful simulation and monitoring.

Applications

Applications of 3-Axis Machining

3-axis machining is widely used in applications where the geometry is relatively simple and the production volumes moderate or high. Typical examples include:

Automotive parts: Engine blocks, simple brackets, and housings.

Consumer products: Flat panels, enclosures, and decorative parts.

Basic molds and dies: For simple shapes and cavities.

Prototyping: Initial designs that do not require complex geometry.

General machining: Drilling, slotting, and pocketing of basic shapes.

Applications of 5-Axis Machining

5-axis machining excels in industries where high precision, complex geometry, and tight tolerances are mandatory:

Aerospace: Turbine blades, airframe components, impellers, and structural parts with complex curvatures.

Medical devices: Prosthetics, implants, surgical instruments requiring complex shapes and biocompatible finishes.

Automotive: Complex molds, engine components, and parts with internal passages.

Energy: Parts for turbines and generators with intricate geometries.

Tool & Die: Complex molds and dies with multi-directional features.

Detailed Comparison & Considerations

Accuracy and Precision

5-axis machining generally provides higher accuracy since fewer setups reduce errors caused by repositioning. With 3-axis machining, multiple setups increase chances of misalignment, leading to dimensional inaccuracies.

Surface Finish

The ability to tilt and rotate the tool in 5-axis machining allows for optimal cutting angles, producing better surface finishes and reducing the need for secondary finishing operations.

Production Efficiency

5-axis machining is more efficient for complex parts due to fewer setups and faster tool paths. However, for simple parts, 3-axis machining may be faster and more economical.

Cost-Benefit Analysis

While 5-axis machining offers advanced capabilities, the higher machine and programming costs must be justified by the complexity of the part or the volume of production. For many applications, 3-axis machining remains the more practical choice.

| Criteria | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Axes of movement | 3 linear (X, Y, Z) | 3 linear + 2 rotational axes |

| Part complexity | Simple to moderate | Highly complex |

| Setup requirements | Multiple setups for complex parts | Usually single setup |

| Cost | Lower | Higher |

| Programming | Easier | More complex |

| Surface finish | Good for flat surfaces | Superior for complex surfaces |

| Cycle time | Longer for complex parts | Shorter due to fewer setups |

| Applications | Automotive, consumer goods, molds | Aerospace, medical, complex molds |

The choice between 5-Axis Machining vs 3-Axis Machining depends primarily on several key factors, including part geometry, production volume, required precision, surface finish, and budget constraints. In the comparison of 5-Axis Machining vs 3-Axis Machining, 3-axis machining remains a cost-effective and efficient solution for producing simple components with basic shapes and minimal contouring. It is widely used in applications where complexity is low and quick turnaround is needed, such as in prototyping or standard manufacturing runs.

However, as part designs become more complex and the demand for tighter tolerances, multi-surface machining, and intricate features increases, 5-axis machining proves to be far more advantageous. It allows for greater flexibility, improved tool access, enhanced accuracy, and significantly shorter cycle times, especially in industries like aerospace, medical device manufacturing, automotive, and high-precision tooling.

When evaluating 5-Axis Machining vs 3-Axis Machining, manufacturers must thoroughly assess their specific production requirements, technical capabilities, and long-term goals. Choosing the appropriate machining technology is essential to maximizing productivity while balancing cost, performance, and part quality. Additionally, investing in the right machining method can lead to fewer setups, reduced human error, and overall improved efficiency in complex manufacturing environments.

Conclusion

Understanding the core differences in 5-Axis Machining vs 3-Axis Machining is essential for choosing the right CNC method for your manufacturing needs. 5-Axis Machining vs 3-Axis Machining highlights two distinct approaches: one offering advanced precision and flexibility, and the other delivering cost-effective solutions for simpler tasks.

When comparing 5-Axis Machining vs 3-Axis Machining, it’s clear that 3-axis machining is best suited for basic geometries and lower-cost production runs. On the other hand, 5-axis machining excels in producing complex parts with tight tolerances and fewer setups, especially in industries like aerospace, medical, and automotive.

Ultimately, evaluating 5-Axis Machining vs 3-Axis Machining helps manufacturers align their production goals with the right technology. By considering the complexity, precision requirements, and budget, you can determine which machining method will deliver the best results for your specific application.

Related posts:

- CNC Machining: 5 Powerful Benefits, How It Works, and Key Applications

- 3D Printing vs Machining: Powerful Comparison of Benefits, Limitations, and Applications

- Machining and Types of Machining.

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses