What is Casting?

Casting is a manufacturing process used to make parts by pouring a liquid material, usually metal, into a mold shaped like the final product. Once the material cools and hardens, it takes on the exact shape of the mold. The solid piece, known as a casting, is then removed and may be cleaned or finished to improve its appearance and performance.

This method is especially useful for creating complex or detailed shapes that would be difficult or too costly to make using other manufacturing techniques. Casting is a basic but important process that has been used for thousands of years and continues to be widely used today due to its flexibility and cost-effectiveness.

The process starts by making a model of the desired object, called a pattern. This pattern is used to form a mold, which is a hollow space in the shape of the final product. Molds can be made from materials like sand, metal, or ceramic, depending on the type of casting being done. After the mold is ready, the chosen material is melted and poured into the mold cavity. As the liquid material cools, it solidifies and takes the shape of the mold. The mold is then removed, and the casting may go through extra steps like trimming, polishing, or machining to meet specific requirements.

Casting is widely used in industries such as automotive, aerospace, construction, and machinery manufacturing. It’s ideal for producing parts like engine blocks, machine housings, pipes, and turbine blades. There are several casting methods, including sand casting, die casting, investment casting, and centrifugal casting, each suited to different needs.

Why Casting is used ?

Another key benefit of casting is its ability to produce large and heavy components such as engine blocks, machine frames, and industrial machinery parts. These types of products often need strong and durable materials like steel or iron, which are well-suited for casting processes. Casting is also highly adaptable, allowing manufacturers to produce anything from single, custom-made items to high-volume production runs, depending on the requirement.

In addition to its size versatility, casting supports a broad range of materials. Metals such as aluminum, copper, bronze, and even some types of plastics can be used, giving manufacturers the flexibility to choose materials based on factors like strength, cost, and performance needs.

Casting also offers production efficiency by reducing the need for extensive machining or assembly work, such as welding. Since the liquid material takes the exact shape of the mold, there is less waste and fewer additional processes required to finish the part. This not only saves time and labor but also makes casting a more economical and resource-efficient manufacturing method.

How Casting is Done ?

Casting is a commonly used manufacturing technique where a material, usually metal, is melted and poured into a mold that has the shape of the desired part. When the material cools and hardens, it takes the shape of the mold, creating the final product. The casting process involves several important steps, each of which plays a crucial role in producing accurate and quality parts.

1. Pattern Making

The first step is to create a pattern, which is an exact replica of the part to be made. This pattern is used to shape the mold cavity. Patterns can be made from materials such as wood, plastic, metal, or wax, depending on the casting method and the level of detail required. Sometimes the pattern is made in multiple pieces to make removing it from the mold easier. It’s also designed to account for metal shrinkage and machining allowances so the finished part meets the required dimensions.

2. Mold Making

Next, the pattern is used to form the mold. The mold contains a hollow cavity shaped exactly like the final product. There are various types of molds, including sand molds (most common and inexpensive), metal molds (used in die casting), and ceramic molds (used in investment casting). The mold also has channels—called the sprue, runners, and gates—that allow molten metal to flow smoothly into the cavity.

3. Melting the Material

The metal or other chosen material is melted in a furnace. The type of furnace depends on the metal and production scale. It’s important to heat the metal to the correct temperature so it flows well and fills every detail of the mold. Any impurities are usually removed during this stage to ensure a good-quality casting.

4. Pouring

Once molten, the metal is poured carefully into the mold through the sprue. It travels through the runners and gates into the mold cavity. Careful pouring is essential to avoid defects like air bubbles, splashing, or incomplete filling, which could weaken or deform the final product.

5. Cooling and Solidification

After pouring, the molten metal cools inside the mold and solidifies. The cooling time varies depending on the metal type and casting size. Proper cooling helps prevent cracks and surface defects and ensures the metal perfectly matches the mold shape.

6. Removing the Casting

When the metal has fully hardened, the mold is opened or broken to remove the casting. For sand molds, the mold is broken apart, while permanent molds are opened and reused. The raw casting usually still has excess metal from the sprue or runners, which must be removed.

7. Finishing

Finally, the casting undergoes finishing processes to improve its shape and surface. This can include trimming off excess material, grinding rough edges, machining for precise dimensions, and polishing or coating for better appearance and protection. After finishing, the part is ready for use or assembly.

Overall, casting is a reliable, efficient process capable of producing a wide range of metal parts—from small, detailed pieces to large, heavy components—making it essential in many industries.

Applications of Casting in Manufacturing

Casting is widely used across various industries to create parts of different sizes and complexities. Common uses include:

Automotive: Making engine blocks, cylinder heads, transmission cases, and brake drums.

Aerospace: Producing turbine blades, engine components, and structural parts.

Construction: Manufacturing pipes, valves, pumps, and heavy equipment bases.

Machinery: Creating machine frames, gearboxes, housings, and pump parts.

Art and Decoration: Crafting sculptures, statues, and decorative items.

Consumer Products: Producing cookware, tools, and hardware items.

Casting is especially useful when parts need detailed shapes or hollow sections that are hard to make with other methods.

Advantages of Casting

Complex Shapes: Casting easily produces intricate and detailed parts that other manufacturing processes may struggle with.

Cost-Effective: Suitable for both small prototype runs and large-scale production.

Material Flexibility: Works with a wide variety of metals like aluminum, steel, bronze, and some plastics.

Large Parts: Ideal for manufacturing large and heavy components.

Minimal Waste: Molten metal fills the mold exactly, reducing leftover material.

Less Machining Needed: Often, cast parts come close to final shape, cutting down on extra machining time and cost.

Disadvantages of Casting

Surface Quality and Accuracy: Cast parts can have rough surfaces and less precise dimensions, often needing additional finishing work.

Defects: Issues like air pockets, shrinkage voids, or impurities can weaken the final product.

Long Cooling Times: Larger castings require extended time to cool and solidify, which can slow production.

Upfront Costs: Creating patterns and molds, especially for complex shapes, can be expensive.

Material Limitations: Some casting methods may not provide the same strength or durability as forged or machined parts.

Various Types of Casting

Based on Mold Type

1. Sand Casting

Uses sand-based molds.

Ideal for large parts and short runs.

Common & cost-effective.

2. Shell Molding

Uses resin-coated sand to form a thin, strong shell mold.

Better surface finish and accuracy than sand casting.

3. Investment Casting (Lost-Wax Casting)

Uses a wax pattern coated with ceramic.

Wax melts away before pouring metal.

Great for intricate, small parts.

4. Lost-Foam Casting

Uses a foam pattern that evaporates when metal is poured.

Good for complex shapes.

5. Plaster Mold Casting

Uses plaster of Paris instead of sand.

Provides fine detail and smooth surface, but not suitable for high-temperature metals.

6. Ceramic Mold Casting

Similar to plaster casting, but with ceramic molds.

Can handle higher temperatures.

Based on Mold Usage

7. Permanent Mold Casting

Uses reusable metal molds.

Better finish and strength than sand molds.

8. Die Casting

High-pressure injection of metal into steel molds (dies).

Fast, accurate, ideal for mass production.

9. Centrifugal Casting

Metal is poured into a spinning mold.

Used for cylindrical or hollow parts.

10. Gravity Die Casting

Metal is poured into a metal mold by gravity, not pressure.

Slower but simpler than pressure die casting.

Based on Pouring Technique

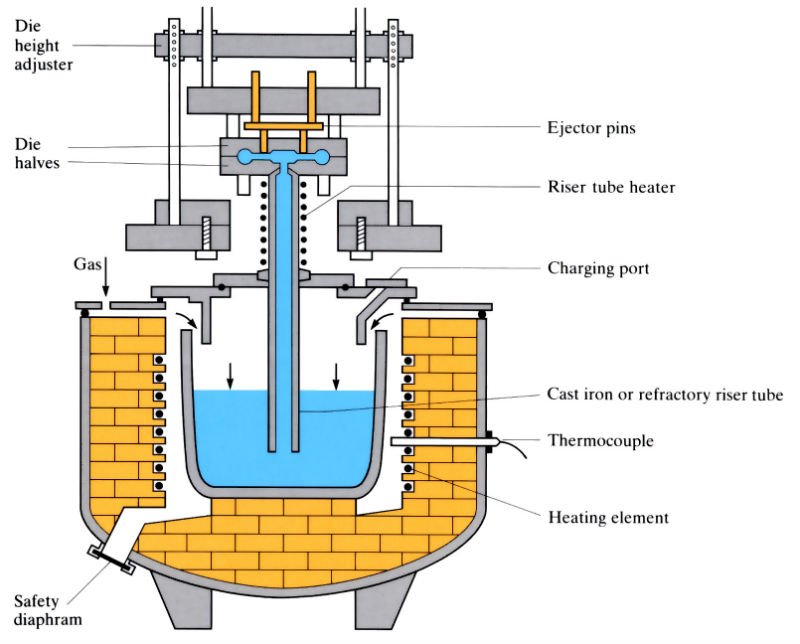

11. Low-Pressure Casting

Metal is pushed into the mold using low gas pressure.

Offers better quality than gravity casting.

12. Vacuum Casting

A vacuum pulls the molten metal into the mold.

Reduces air pockets and defects.

13. Squeeze Casting

Combines casting and forging: metal is poured and then pressed.

Produces very strong parts.

Continuous Casting

14. Continuous Casting

Used in the metal industry to make long shapes (like rods, billets, slabs).

Molten metal is continuously poured and solidified as it moves.

Sand Casting

Sand casting is a common and traditional method used to make metal parts, especially those that are large, heavy, or made in small numbers. The process starts with making a pattern, which is a model of the final object. This pattern is slightly bigger than the actual part to allow for the metal to shrink when it cools. Patterns can be made from materials like wood, metal, plastic, or foam. The pattern is used to shape the space inside a mold where the hot metal will be poured.

If the part needs to have hollow spaces or holes inside, cores are used. These are made from special sand mixed with chemicals to make them strong. The cores are placed inside the mold to block the metal from flowing into certain areas.

Next, the mold is prepared. The pattern is placed inside a box called a flask, and sand is packed tightly around it. This sand is called green sand because it is slightly wet and can hold its shape. The mold is usually made in two halves: the top part is called the cope and the bottom is the drag. After the sand is packed, the pattern is removed, leaving behind a hollow shape. Passages called the sprue, runners, and gates are also made to guide the molten metal into the mold. Small holes called vents may be added to let out gases when the metal is poured.

Once the mold is ready, any cores are placed inside, and the cope and drag are put together and clamped tightly. The metal is then melted in a furnace until it becomes liquid. This molten metal is carefully poured into the mold through the sprue and flows into the mold cavity. Workers must wear safety gear during this step because the metal is extremely hot and dangerous.

After pouring, the metal is left to cool and harden inside the mold. How long this takes depends on the type of metal and the size of the part. Once it has cooled down and solidified, the mold is broken open in a process called shakeout, and the metal part is taken out. The used sand can often be cleaned and reused.

The rough metal part, called a casting, still has extra bits like the gates and risers attached, and there may be some sand stuck to it. These are removed during cleaning and fettling using tools like grinders or machines. The part may also go through further inspection to check for any problems, using methods like visual checks, measuring tools, or even X-rays.

In the final step, the part may be finished or heat-treated to improve its strength or other properties. Sometimes it is also machined to get a smooth surface or exact size.

To sum up, sand casting involves several main steps: making the pattern, preparing the mold and cores, pouring the metal, cooling, removing the casting, cleaning it, inspecting it, and finishing it. It’s a simple and cost-effective method that works well for making big or complex metal parts, although it may not give the smoothest finish or most precise dimensions.

Advantages of Sand Casting

Low Cost of Molds

Sand molds are inexpensive to produce, making sand casting ideal for low-volume or custom parts.Simple Process

The process is straightforward and doesn’t require highly specialized equipment.Versatile for Size and Shape

Suitable for both small and large components, including very large parts like engine blocks or machine frames.Handles Complex Geometries

Intricate shapes, internal cavities, and hollow sections can be created using sand casting with the help of cores.Wide Range of Metals

Works with almost any metal, including cast iron, steel, aluminum, bronze, and more.Reusable Sand (with Treatment)

Much of the sand used in the process can be reclaimed, treated, and reused, reducing waste.

Disadvantages of Sand Casting

Rough Surface Finish

Castings often have a coarse surface and may require additional finishing or machining.Lower Dimensional Accuracy

Compared to other casting methods like die casting or investment casting, sand casting has looser tolerances.Slower Production Rate

The process takes more time due to mold preparation, cooling, and shakeout, making it less ideal for high-volume production.High Labor Involvement

Many steps are manual, which increases labor costs and the chance of human error.Mold Breakage

Sand molds are not reusable, so a new mold must be made for each part.Defects Possible

Sand casting is more prone to defects like porosity, shrinkage, and mold shift if not carefully controlled.

Shell Moulding

Shell moulding is a more modern casting process compared to sand casting. It is often used for making metal parts that require a smoother surface, more precise dimensions, or are produced in larger quantities. This method uses a pattern like sand casting, but instead of packing sand around the pattern, it uses a special resin-coated sand that forms a thin, hard shell when heated.

The process begins with a metal pattern, usually made of iron or steel, which has the exact shape of the final part. This pattern is heated to a high temperature, typically around 175–350°C (350–660°F). Once it’s hot, it is covered with fine sand that has been coated with a thermosetting resin, usually phenolic. When the hot pattern comes in contact with this resin-coated sand, the resin melts and hardens quickly, forming a thin shell around the pattern.

After a few seconds, the mold is turned upside down so that any loose, non-hardened sand falls away. This leaves a hollow shell around the pattern, which is then baked in an oven or with heated air to fully harden it and improve its strength. This shell forms one half of the mold. The same process is repeated to create the other half.

If the part needs hollow sections, cores made from the same resin-coated sand can be used. These are placed between the two halves of the shell mold before pouring.

Once both halves of the shell mold are ready and cooled, they are assembled together with any cores inserted in place. The two shell halves are clamped tightly to prevent any leakage during metal pouring. The molten metal is then melted in a furnace and poured into the mold cavity through a sprue. Since shell molds are thinner than traditional sand molds, they require less material and allow faster heat transfer, helping the metal solidify more quickly and evenly.

After pouring, the metal cools and hardens inside the mold. Once solidified, the shell is broken away to remove the casting. Unlike sand casting, shell molds are not reusable, but the process creates less loose sand and produces a cleaner working environment.

The raw casting still has extra parts like gates and risers, which are removed during the cleaning and fettling stage. The surface finish of shell mold castings is usually smoother, and the dimensional accuracy is better than traditional sand casting. However, final machining may still be required depending on the application.

Parts made using shell moulding are often inspected for quality using visual checks, dimensional measurements, or non-destructive testing methods such as X-ray or ultrasonic inspection.

In the final stage, the casting may be heat-treated to improve its mechanical properties or machined for precision.

To sum up, shell moulding involves several key steps: heating the pattern, forming and curing the shell, assembling the mold and cores, pouring the metal, cooling, removing the casting, cleaning, inspecting, and finishing. It offers better surface quality and accuracy than sand casting, making it suitable for medium- to high-volume production of complex metal parts.

Advantages of Shell Moulding

Better Surface Finish

Shell moulding produces a much smoother surface compared to traditional sand casting, reducing the need for extensive machining.Higher Dimensional Accuracy

Parts cast using shell moulding have tighter tolerances and better precision, making them suitable for applications requiring accuracy.Good Reproducibility

Since the molds are made using precise patterns, this process is excellent for producing consistent, high-quality parts in larger quantities.Complex Shapes Possible

With the use of sand cores, shell moulding can produce complex geometries, including hollow sections and undercuts.Reduced Machining

The improved accuracy and finish often reduce or eliminate the need for further machining or finishing.Faster Cooling and Solidification

The thin shell molds allow better heat transfer, resulting in faster cooling and shorter cycle times.Cleaner Process

The resin-bonded sand used in shell moulding produces less dust and waste, offering a cleaner working environment.

Disadvantages of Shell Moulding

Higher Cost of Patterns and Equipment

Metal patterns and heating equipment are required, making the initial setup more expensive than traditional sand casting.Limited to Medium-Sized Parts

Shell moulding is best suited for small to medium-sized components; it’s not ideal for very large castings.Not Suitable for All Metals

While many metals can be used, shell moulding may not be ideal for extremely high-temperature alloys.Non-Reusable Molds

Like sand casting, the shell mold is broken after each use, so new molds are required for every part.Brittle Molds

Shell molds are more fragile than traditional sand molds and can crack if not handled properly.

Investment Casting (Lost-Wax Casting)

Investment casting, also called lost-wax casting, is a method used to make metal parts that are very detailed, accurate, and smooth. It’s a very old technique but is still popular today, especially for parts that have complex shapes or need to be very precise.

The process starts by making a wax model of the part. This wax model looks exactly like the final metal object. If many parts are being made at once, several wax models are joined together around a central wax rod to form something called a “wax tree.”

Once the wax models are ready, they are dipped into a special liquid ceramic material. Then, fine sand is sprinkled on them. This step is repeated several times until a strong, hard shell forms around the wax. Each layer is allowed to dry before adding the next one.

When the ceramic shell is thick and dry, the whole thing is heated so that the wax melts and drains out. This leaves a hollow ceramic mold in the shape of the part.

Next, the ceramic mold is heated again to make it stronger and ready to hold molten metal. Then, hot liquid metal is poured into the mold, filling the space left by the melted wax.

After the metal cools and hardens, the ceramic shell is broken off, and the metal parts are removed. Any extra metal, like the parts that connected the castings to the main rod, is cut or ground off.

The finished parts may then be cleaned, polished, or machined if needed. They are also checked for quality to make sure there are no defects. Some parts may be heat-treated to make them stronger or more durable.

To sum up, investment casting includes making a wax model, coating it with ceramic, melting out the wax, pouring in metal, and then cleaning and finishing the part. It’s great for making small to medium-sized parts that need fine details, a smooth surface, and high accuracy—like those used in aircraft, medical tools, and machinery.

Advantages of Investment Casting

High Precision

Investment casting can produce parts with very accurate dimensions and fine details, making it ideal for complex designs.Smooth Surface Finish

The parts usually come out with a smooth surface, which reduces the need for extra polishing or machining.Can Create Complex Shapes

It’s easy to cast parts with tricky shapes, thin walls, or hollow sections that would be hard to make with other methods.Wide Range of Materials

Many different metals can be used, including steel, aluminum, bronze, and more.Minimal Waste

Because the part is formed so precisely, there’s very little excess material, which saves resources.Good for Small Parts

It’s especially useful for making small or detailed components, like those used in aerospace, dental tools, or jewelry.

Disadvantages of Investment Casting

Higher Cost

It can be more expensive than other casting methods, especially for low-volume production, due to the cost of materials and mold preparation.Longer Production Time

The process involves many steps (wax pattern making, coating, drying, etc.), so it takes more time.Size Limitations

It is best for small to medium-sized parts. Making very large parts can be difficult and costly.Fragile Molds

The ceramic shell can be delicate and may break if not handled carefully during production.Not Ideal for Very High Volumes

While it works well for medium batches, other methods like die casting are faster and more cost-effective for mass production.

Lost-Foam Casting

Lost foam casting is a modern casting method used to make metal parts with complex shapes, fine details, and smooth surfaces. It is somewhat similar to investment casting, but instead of using wax, it uses foam to create the pattern of the part.

The process begins by making a foam model of the part. This foam pattern is made from a special material called polystyrene, which is lightweight and easy to shape. The foam model looks exactly like the final metal part. If several parts need to be made together, they can be connected to a foam rod to create a structure called a foam tree, just like in investment casting.

Once the foam pattern is ready, it is coated with a thin layer of ceramic slurry to give it strength and protect it from the molten metal. After drying, the coated foam pattern is placed into a box and surrounded by dry, unbonded sand. The sand is packed tightly around the pattern using vibrations to ensure that the mold holds its shape during casting.

Next, the molten metal is poured directly onto the foam pattern. As the hot metal enters the mold, it vaporizes the foam and takes its place, filling the exact shape of the pattern. Since the foam disappears during pouring, the process is called “lost foam” casting.

After the metal has completely filled the mold and cooled down, the sand is removed, and the solid metal part is taken out. Because there’s no need to remove wax or break a ceramic shell like in investment casting, the process is simpler and creates less waste.

The casting may still have extra parts like gates or risers, which are cut or ground off. The part is then cleaned, inspected, and possibly machined or heat-treated to improve its strength or fit.

Advantages of Lost Foam Casting

Complex Shapes Made Easily

It can produce parts with complex designs, fine details, and internal shapes without needing multiple molds or cores.Good Surface Finish

The parts usually come out with a smooth surface, which reduces the amount of polishing or machining needed afterward.No Need to Remove Pattern

The foam pattern burns away when the metal is poured, so there’s no need to take the pattern out of the mold, which simplifies the process.Fewer Joints and Welds Needed

Complex shapes can be cast in one piece, reducing the need for welding or assembly of multiple parts.Less Waste and Lower Cost for Some Parts

The process produces less scrap metal and can be cost-effective for complex or large parts made in medium to large quantities.Faster Mold Setup

Since the sand used is unbonded and dry, it’s quicker and easier to pack around the foam pattern.

Disadvantages of Lost Foam Casting

Foam Patterns Are Single-Use

Each foam pattern can only be used once, so new patterns must be made for every casting, which can increase cost and time for small batches.Pattern Handling Can Be Tricky

Foam is delicate and can be easily damaged during handling or while being coated.Requires Special Equipment

The process needs vibration tables and proper ventilation to safely remove the gases from burning foam.Not Ideal for Very Small Parts

Lost foam casting works better for medium to large parts. Very small parts might not justify the cost and setup time.Environmental Concerns

Burning foam produces gases that need to be controlled with proper ventilation and safety measures.Material Limitations

While many metals can be used, extremely high-temperature alloys may not be suitable for this process.

Plaster Mold Casting

Plaster mold casting is a casting process used to make small, detailed metal parts with smooth surfaces and precise shapes. It is similar to sand casting, but instead of sand, it uses plaster of Paris (a mixture of gypsum and other additives) to create the mold.

The process starts by making a pattern of the final part, usually out of wax, metal, or plastic. This pattern is placed in a special container called a flask. Then, liquid plaster is poured around the pattern and allowed to harden. The hardened plaster forms a mold with the exact shape of the pattern.

Once the plaster sets, the pattern is carefully removed, leaving behind a hollow space. The mold is then dried in an oven to remove moisture and increase strength. Drying is important because any moisture left in the mold can cause problems when hot metal is poured in.

After drying, molten metal is poured into the plaster mold. The metal fills the mold cavity and takes the exact shape of the part. After the metal cools and solidifies, the plaster mold is broken away, and the metal casting is removed.

The casting may then go through cleaning, trimming, and machining if needed. It is also inspected for accuracy and quality before being used.

Plaster mold casting is mostly used for non-ferrous metals like aluminum, magnesium, copper, and zinc, and is best suited for small production runs of parts that require fine details and good surface finish.

Advantages of Plaster Mold Casting

Very Smooth Surface Finish

Produces castings with smooth surfaces, reducing the need for polishing or extra machining.High Dimensional Accuracy

The plaster captures fine details and provides good control over final dimensions.Good for Complex Shapes

Allows casting of parts with thin walls, fine features, and complex geometries.Lower Tooling Costs

Patterns and molds are cheaper compared to die casting or permanent mold casting.Low Pouring Temperatures

Works well with metals that melt at lower temperatures, making it energy-efficient.

Disadvantages of Plaster Mold Casting

Not Suitable for High-Temperature Metals

Plaster molds cannot handle very high temperatures, so it’s limited to non-ferrous metals only.Longer Drying Time

The molds must be carefully dried before pouring metal, which adds time to the process.Lower Strength Molds

Plaster molds are more fragile and can break or crack easily if not handled carefully.Not Ideal for Large Parts

Best suited for small to medium-sized parts due to mold strength and drying limitations.Mold is Single-Use

Like sand and shell molds, plaster molds are destroyed after each casting.

Ceramic Mold Casting

Ceramic mold casting is a manufacturing process used to make metal parts with fine details, accurate shapes, and smooth surfaces. It is similar to investment casting and plaster mold casting but uses a strong ceramic material to form the mold.

The process starts with creating a pattern of the part, usually made of wax, plastic, or metal. This pattern is placed in a container, and a liquid ceramic slurry (a mixture of ceramic materials and a binder) is poured around it. The ceramic fills all the small spaces around the pattern and hardens over time to form a strong mold.

Once the ceramic mold has hardened, the pattern is removed. If it’s made of wax or plastic, it is melted or burned out, leaving behind a hollow mold that has the exact shape of the part to be made. The mold is then fired (heated in a furnace) to make it even stronger and ready for pouring metal.

Next, molten metal (like stainless steel, aluminum, bronze, or other alloys) is poured into the ceramic mold. The metal fills the mold cavity and takes the exact shape of the pattern. After the metal cools and solidifies, the ceramic mold is broken away to reveal the casting.

The final part is then cleaned, trimmed, and inspected, and may go through machining or heat treatment if required.

Ceramic mold casting is often used when high-quality metal parts with excellent surface finish and detail are needed, such as in the aerospace, military, automotive, and medical industries.

Advantages of Ceramic Mold Casting

High Surface Quality

Produces parts with a very smooth surface and fine detail, reducing the need for finishing.Excellent Dimensional Accuracy

Allows for tight tolerances and detailed features, making it good for precision parts.Can Withstand High Temperatures

Ceramic molds can handle metals with high melting points like stainless steel or titanium.Good for Complex Shapes

Great for parts with thin walls, intricate designs, and undercuts.Low Tooling Costs for Small Batches

Cost-effective for short production runs or custom parts.

Disadvantages of Ceramic Mold Casting

More Expensive Than Sand Casting

The materials and steps involved can be costly, especially for large parts or mass production.Longer Production Time

Making and curing ceramic molds takes time, which can slow down the process.Mold is Single-Use

Each mold is destroyed after casting, so it must be remade for every new part.Brittle Molds

Ceramic molds can be fragile and must be handled carefully to avoid cracking before casting.Limited to Smaller Parts

Best suited for small to medium-sized parts due to the fragility and cost of large ceramic molds.

Permanent Mold Casting

Permanent mold casting is a casting process where the same mold is reused multiple times to make metal parts. Unlike sand, plaster, or ceramic molds that are broken after one use, permanent molds are made of strong metals like steel or cast iron, allowing them to be used over and over again.

The process starts by preparing the mold, which is made in two halves. These halves fit together to form a hollow space in the exact shape of the part to be made. Before casting, the inside of the mold is usually coated with a special material (called a mold release agent) to prevent the metal from sticking.

Next, molten metal is poured into the mold, usually using gravity (called gravity die casting), although sometimes pressure or vacuum is used for better results. The metal fills the mold cavity and takes the shape of the part.

Once the metal cools and solidifies, the mold is opened, and the part is removed. Because the mold is made of metal, it cools the casting quickly, which can help improve the strength and surface quality of the part.

The finished casting may then go through trimming, machining, or heat treatment if needed. The mold can then be closed again and reused for the next part.

Permanent mold casting is commonly used for non-ferrous metals like aluminum, magnesium, bronze, and zinc. It’s ideal for medium- to high-volume production where consistent quality and good surface finish are important.

Advantages of Permanent Mold Casting

Reusable Molds

The same mold can be used many times, saving time and cost for larger production runs.Good Surface Finish

Produces smoother surfaces than sand casting, which reduces finishing work.Stronger Castings

The faster cooling in metal molds makes the cast parts denser and stronger.Better Dimensional Accuracy

The rigid mold holds its shape, allowing for more precise and consistent parts.Faster Production

No need to make a new mold for every part, so parts can be made quickly and repeatedly.

Disadvantages of Permanent Mold Casting

High Initial Cost

Making the metal mold is expensive, so it’s not ideal for small quantities.Limited to Simpler Shapes

Complex or intricate parts may not be suitable, especially if undercuts are involved.Size Limitations

Best for small to medium parts; large parts require big, heavy, and costly molds.Only for Low-Melting Metals

Typically used for metals like aluminum or zinc. High-temperature metals like steel can damage the mold.Tool Wear Over Time

After many uses, the mold may wear out and need repair or replacement.

Die Casting

Die casting is a metal casting process used to make high-volume, high-precision parts with a smooth surface and accurate dimensions. It uses a metal mold (called a die) that can be reused many times. This process is especially common for making parts out of non-ferrous metals like aluminum, zinc, and magnesium.

In die casting, the metal dies (molds) are made in two halves that fit together to form the shape of the part. These dies are placed inside a special die casting machine.

The process starts with melting the metal in a furnace. Once it becomes liquid, the metal is injected into the die at high pressure. This pressure makes sure the molten metal fills every corner of the mold quickly and completely.

After injection, the metal is held under pressure until it cools and solidifies. Once the part is solid, the machine opens the die, and the part is ejected using pins.

The part is then trimmed, cleaned, and finished as needed. Any extra bits of metal, like sprues and flash (thin excess metal), are removed. Sometimes, the part may be machined or heat-treated to meet final requirements.

Die casting is ideal for making a large number of parts that must be strong, lightweight, and accurate, such as automotive components, electronic housings, tools, and appliances.

Advantages of Die Casting

High Production Speed

Very fast process—suitable for making thousands of parts quickly.Excellent Surface Finish

Produces smooth and clean surfaces, reducing the need for polishing or grinding.Great Dimensional Accuracy

Parts come out very precise, often requiring little to no machining.Reusable Metal Dies

The molds last a long time, making it cost-effective for mass production.Thin Walls and Complex Shapes

Can produce lightweight parts with fine details and thin walls.

Disadvantages of Die Casting

High Setup Cost

Making the dies and setting up the machine is expensive, so it’s not good for small batches.Limited to Non-Ferrous Metals

Usually used only for metals like aluminum, zinc, and magnesium—not for steel or iron.Not Ideal for Very Large Parts

Better suited for small to medium-sized parts due to equipment limitations.Porosity Can Be an Issue

Trapped air or gas can cause small holes (porosity) inside the part, which may weaken it.Limited Mold Changes

Once a die is made, changing the design is costly and time-consuming.

Centrifugal Casting

Centrifugal casting is a process used to make round, cylindrical, or ring-shaped metal parts, such as pipes, tubes, bearings, and rings. What makes this method special is that the mold spins rapidly, and the molten metal is poured into it while it’s spinning.

The process begins by preparing a round or cylindrical mold, usually made of metal. This mold is mounted on a machine that can spin at high speeds. The mold is heated before casting to help the metal flow smoothly and to reduce thermal shock.

Once the mold is spinning, molten metal is poured into the center. As the mold rotates, centrifugal force pushes the liquid metal outward to the inner walls of the mold. This force helps remove air bubbles and impurities, causing them to move toward the center (which is usually later removed or machined out).

The spinning continues while the metal cools and solidifies, forming a dense, strong casting. After cooling, the machine stops spinning, and the casting is removed from the mold.

The result is a high-quality metal part with few defects and a dense, even structure. Centrifugal casting is used for both horizontal and vertical orientations, depending on the shape of the part.

Advantages of Centrifugal Casting

Strong and Dense Castings

The spinning action forces out gas and impurities, making the part solid and high in strength.Ideal for Cylindrical Parts

Perfect for round shapes like pipes, tubes, bushings, and rings.Less Defects

Reduced chances of porosity (air bubbles), cracks, or inclusions.Good Material Usage

Produces less waste, and excess material in the center can be easily removed.No Need for Cores in Hollow Parts

The centrifugal force creates hollow shapes without the need for sand or ceramic cores.

Disadvantages of Centrifugal Casting

Limited to Round Shapes

Only suitable for cylindrical or symmetrical parts—can’t be used for complex or irregular shapes.High Equipment Cost

Requires special spinning machines and molds, which can be expensive.Size Limitations

Mostly used for medium-sized parts; very large castings need large, expensive equipment.Center May Need Machining

Impurities collect in the center and often need to be removed by machining.Not Ideal for Small Production Runs

Best for medium to high volumes; setup costs are too high for small quantities.

Gravity Die Casting

Gravity die casting is a metal casting process used to make strong and precise metal parts by pouring molten metal into a reusable metal mold using gravity only—without applying any extra force or pressure. It’s also known as permanent mold casting.

The process starts by preparing the metal mold (die), which is made from steel or cast iron. The mold usually comes in two halves that are put together to form the shape of the part. Before casting, the inside of the mold is coated with a lubricant or release agent to make sure the metal doesn’t stick and to help control the cooling rate.

Once the mold is ready, molten metal (such as aluminum, bronze, or magnesium) is poured into the mold from above. Gravity pulls the metal down, filling the cavity completely. Since no pressure is used, the flow of metal is slower and more controlled than in high-pressure die casting.

After pouring, the metal is allowed to cool and solidify inside the mold. The metal mold cools the part faster than sand molds, giving it a tighter grain structure and better strength.

Once the part is solid, the mold is opened, and the casting is removed. It may still have extra bits of metal (like runners and risers), which are cut, trimmed, or machined in the finishing steps.

Gravity die casting is commonly used in the automotive, aerospace, and machinery industries for making parts like engine components, wheels, housings, and brackets.

Advantages of Gravity Die Casting

Reusable Metal Molds

The dies can be used many times, reducing cost over long production runs.Better Surface Finish

Produces smoother surfaces than sand casting, reducing the need for extra finishing.Higher Strength Castings

Faster cooling in metal molds creates stronger and denser metal parts.Good Dimensional Accuracy

Produces consistent parts with accurate shapes and sizes.Lower Porosity than Sand Casting

Controlled metal flow reduces gas pockets and improves part quality.

Disadvantages of Gravity Die Casting

High Initial Cost

Making the metal molds is expensive, so it’s not cost-effective for small runs.Limited to Simple or Moderately Complex Shapes

Not suitable for parts with very complex shapes or deep undercuts.Slow Production Compared to Pressure Casting

Since it uses gravity alone, the process is slower than high-pressure die casting.Manual Pouring Can Be Inconsistent

If done by hand, the quality can vary depending on the operator’s skill.Best for Non-Ferrous Metals

Mostly used for aluminum, magnesium, and copper alloys—not ideal for iron or steel.

Low-Pressure Casting

Low pressure die casting is a metal casting process used to make high-quality, precise metal parts by using low pressure to fill a reusable metal mold with molten metal. It is especially useful for creating complex shapes and reducing porosity in the final product.

The process begins with a metal mold (also called a die), typically made from steel. Like in gravity die casting, the mold usually comes in two halves that are joined together to create the desired shape. Before casting, the inside of the mold is coated with a release agent or lubricant to prevent sticking and to help with cooling control.

Instead of pouring the molten metal into the mold from above, low pressure die casting uses a sealed furnace located below the mold. A metal tube, or riser tube, connects the furnace to the mold cavity. When the process starts, low pressure—usually between 0.3 and 1.5 bar—is applied to the surface of the molten metal in the furnace. This pressure gently pushes the metal up through the tube and into the mold cavity.

The metal fills the mold in a very controlled and consistent way, which helps reduce turbulence and the risk of air entrapment. This results in castings with fewer internal defects and better mechanical properties. The pressure is maintained while the metal solidifies inside the mold.

Once the metal has cooled and hardened, the pressure is released, and the casting is removed from the mold. Like with gravity die casting, any extra metal from channels or risers is removed through trimming or machining during finishing.

Low pressure die casting is widely used in industries like automotive and aerospace, especially for making lightweight aluminum components such as wheels, suspension parts, cylinder heads, and structural parts that require excellent strength and dimensional accuracy.

Advantages of Low Pressure Die Casting

Better Metal Flow Control

The use of controlled low pressure ensures smooth and uniform filling of the mold, minimizing turbulence and defects.High-Quality Castings

Produces parts with low porosity, excellent mechanical properties, and good surface finish.Suitable for Complex Shapes

Ideal for thin-walled and intricate designs that may be difficult to achieve with gravity casting.Improved Material Utilization

Less metal waste due to precise filling and fewer risers or feeders.Consistent and Repeatable Process

Well-suited for mass production where uniformity and precision are critical.Stronger Parts

Slow and controlled solidification results in a fine grain structure and stronger parts compared to sand casting.

Disadvantages of Low Pressure Die Casting

High Initial Equipment Cost

Requires specialized equipment, including a sealed furnace and pressurization system, which increases setup cost.Slower Cycle Time

The process is slower than high-pressure die casting, especially during filling and cooling stages.Limited Part Size

Not suitable for very large or heavy castings, as maintaining low pressure becomes impractical for larger volumes.Complex Setup and Operation

Requires skilled operators and careful control of temperature, pressure, and timing.Higher Maintenance Needs

More moving parts and systems (like pressurized furnaces) mean more frequent and specialized maintenance.

Vacuum Casting

Vacuum casting is a metal casting process used to produce high-precision parts with excellent surface finish and minimal internal defects. It works by drawing molten metal into a mold using a vacuum instead of relying on gravity or pressure. This method is particularly effective for casting parts with complex geometries and thin walls, and for reducing air entrapment and porosity in the final product.

The process begins with the preparation of a mold, which is often made from high-temperature resistant materials such as steel or ceramic, depending on the type of metal being cast. In some applications—especially for prototyping or resin casting—silicone molds are also used. The mold typically consists of two halves that are aligned and sealed together to create the desired cavity shape. Before casting, a release agent is applied inside the mold to prevent sticking and to aid in the smooth removal of the part.

Instead of pouring or pushing the molten metal into the mold, vacuum casting places the mold inside a sealed vacuum chamber. The molten metal is held in a separate container or crucible connected to the mold via a gating system. Once the vacuum chamber is sealed, a vacuum is applied. The pressure difference causes the molten metal to be drawn into the mold cavity evenly and without turbulence.

This smooth and controlled filling reduces the risk of air bubbles and oxide formation, resulting in castings with superior internal quality and fewer defects. After the mold is completely filled, the vacuum is maintained during solidification to ensure consistent metal flow and compact structure.

Once the metal has cooled and solidified, the vacuum is released, and the mold is opened to remove the finished part. Any excess metal from the gates or runners is then trimmed or machined in post-processing.

Vacuum casting is commonly used in the aerospace, automotive, and medical device industries for producing high-strength components where integrity and performance are critical. It is also popular in rapid prototyping, especially when using resin materials, for creating detailed and accurate pre-production models.

Advantages of Vacuum Casting

Excellent Surface Finish

Produces smooth, detailed surfaces, reducing the need for post-processing or machining.Low Porosity

The vacuum removes air from the mold cavity, significantly reducing gas-related defects like air pockets or bubbles.High Dimensional Accuracy

Provides tight tolerances and precise reproduction of mold details, making it ideal for prototype and small-batch production.Suitable for Complex Geometries

Effectively casts intricate designs and thin-walled sections that may be difficult with traditional methods.Reduced Material Waste

Controlled material flow and minimal turbulence reduce spillage and leftover material.Applicable to Various Materials

Can be used with metal alloys, plastics, or resins, depending on the application.

Disadvantages of Vacuum Casting

Higher Equipment and Operating Costs

Requires a vacuum chamber and specialized machinery, leading to increased capital investment and maintenance costs.Not Ideal for High-Volume Production

Generally used for prototyping or small series, as the cycle time and process setup are slower than mass production techniques.Limited Mold Life (for resin casting)

When using silicone molds (especially in resin vacuum casting), mold wear is an issue after 20–30 castings.Size Limitations

The size of parts is restricted by the vacuum chamber capacity, making it less suitable for very large components.Longer Preparation Time

Mold setup, degassing, and vacuum processing can increase overall lead time for each part.

Squeeze Casting

Squeeze casting is a metal casting process used to make strong and high-quality metal parts. It combines casting and forging by pouring molten metal into a mold and then pressing it while it cools. This helps remove air pockets and makes the part stronger and more solid.

The process starts with a metal mold made from strong steel. The mold usually has two halves—a bottom and a top. Before casting, the inside of the mold is sprayed with a release agent to stop the metal from sticking and to help control cooling.

Molten metal (like aluminum or magnesium) is poured into the bottom half of the mold. Then, the top half comes down and pressure is applied using a hydraulic press. This pressure is kept on the metal as it cools and hardens inside the mold.

Applying pressure while the metal solidifies helps push it into every corner of the mold, removes any trapped air, and makes the part stronger and more compact. The metal also cools quickly in the metal mold, which improves its strength and structure.

Once the metal has cooled and hardened, the pressure is released, the mold is opened, and the part is taken out. Any extra metal around the edges is trimmed off in the finishing step.

Squeeze casting is often used in car, airplane, and machinery parts where strong and lightweight components are needed, like suspension arms, brake parts, and engine parts.

Advantages of Squeeze Casting

Stronger Parts

The pressure applied during cooling makes the metal denser and stronger, similar to forged parts.Low Porosity

It greatly reduces air pockets or shrinkage inside the part, leading to better quality.Good Surface Finish

The parts have a smoother surface, reducing the need for extra finishing work.High Precision

It allows for accurate shapes and tight tolerances, which is useful for complex parts.Better Mechanical Properties

The parts have good strength, hardness, and wear resistance.Efficient Cooling

The metal mold cools the part faster, improving production speed and grain structure.

Disadvantages of Squeeze Casting

High Equipment Cost

The process requires a strong hydraulic press and high-quality molds, which can be expensive.Limited to Certain Shapes

It works best for parts that are not too complex or very large.Slower Than High-Pressure Die Casting

Since pressure must be maintained while the metal solidifies, the process takes more time.Not Ideal for High-Volume Production

It is better for medium-sized production runs, not for very large quantities like in die casting.More Complex Setup

The process setup and control require skilled operators and close monitoring.

Continuous Casting

Continuous casting is a metal casting process used to make long shapes of metal, such as slabs, billets, or rods, in a continuous and efficient way. Instead of pouring metal into separate molds, this process allows the molten metal to flow nonstop into a mold and form a solid shape as it cools.

The process starts by pouring molten metal (like steel, copper, or aluminum) from a ladle into a copper mold that is water-cooled. As the metal touches the mold walls, it begins to solidify on the outside while the inside is still liquid.

The partially solid metal is then slowly pulled downward (or horizontally) using rollers. As it moves, it continues to cool and harden into a solid piece. The metal is then cut into desired lengths by mechanical shears or torches.

Continuous casting is widely used in the steel industry and for producing large amounts of metal bars, rods, billets, or slabs that will later be rolled or forged into final products.

Advantages of Continuous Casting

High Production Efficiency

Produces metal continuously, which is faster than batch casting methods.Better Metal Quality

Fewer defects like shrinkage or air pockets, and a uniform grain structure.Less Waste

More metal is used effectively, reducing scrap and leftover material.Lower Costs

Continuous casting saves time, energy, and labor, making it more economical for large-scale production.Good Surface Finish

The process produces a smoother surface, reducing the need for extra machining.

Disadvantages of Continuous Casting

High Initial Setup Cost

The equipment and machinery required are expensive and complex.Limited to Simple Shapes

Mostly used for basic, straight shapes like slabs, billets, and blooms—not for detailed or intricate parts.Not Suitable for Small Production Runs

It is most cost-effective for mass production, not for small quantities.Requires Continuous Operation

The process must be carefully controlled and maintained to run smoothly without interruption.High Skill and Maintenance Needed

Operating and maintaining the system requires trained workers and regular care.

No related posts.