Inspection Methods in Forging

In a forging plant, raw material inspection entails checking materials to ensure they meet defined standards and requirements before use in the forging process. This involves evaluating their physical, chemical, and mechanical properties, and confirming compliance with relevant industry specifications.

Raw Material Verification

- Visual Inspection

- Chemical Composition Analysis

- Mechanical Properties Testing

- Nondestructive Testing

- Metallurgical Testing

Visual Inspection

Visual inspection is the first and one of the most critical steps in the inspection process of raw materials before they enter the forging stage.

This initial inspection involves a careful and thorough visual examination of the surface and general condition of raw materials such as metal bars, rods, billets, or ingots.

The purpose of this inspection is to detect any obvious issues or visible defects that could compromise the integrity of the forging process or the quality of the final product.

During visual inspection, trained personnel or quality inspectors closely observe the raw materials for problems such as cracks, rust, or corrosion.

Cracks are serious defects that can severely weaken the material, leading to failures during or after forging.

Rust and corrosion not only lower the material’s strength but also affect its structural reliability and forgeability.

The inspection process also includes checking for surface defects such as dents, scratches, pits, folds, or any physical damage that might have occurred during storage, transportation, or earlier handling operations.

These surface flaws can create stress concentrations or uneven material flow during forging, which may result in poor-quality forged parts.

A crucial part of the visual inspection is ensuring the raw material is clean and free from any contaminants.

Inspectors look for the presence of oil, grease, dirt, paint, or other foreign substances.

If these contaminants are not removed before forging, they can interfere with heat transfer, cause surface imperfections, or even lead to forging defects.

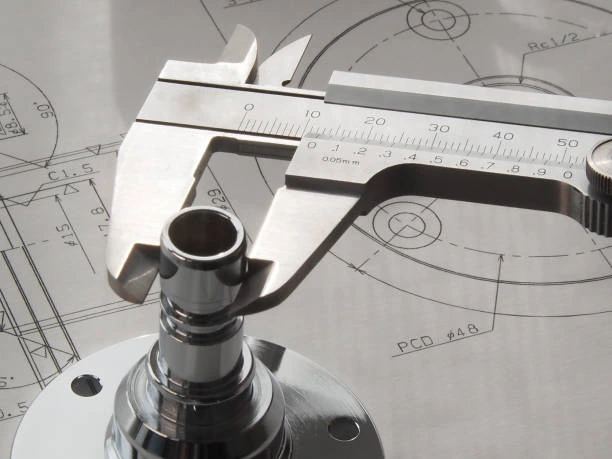

Inspectors also perform a dimensional inspection to verify that the raw material conforms to the required size, shape, and specifications as per production plans.

Using incorrectly sized or shaped material can lead to dimensional nonconformity in forged parts or inefficient forging operations.

Although visual inspection may appear to be a basic quality control step, it is an essential part of the overall inspection and quality assurance system.

By identifying and eliminating substandard material early, visual inspection helps prevent downstream issues, minimizes rework, and improves product consistency.

It supports high-quality standards and enhances efficiency across the entire forging process.

What is Checked in the Visual Inspection?

Cracks

Rust or Corrosion

Surface Defects

Cleanliness

Shape and Size

Why Visual Inspection Important?

Prevents defective material from entering production.

Saves time and cost by reducing scrap and rework.

Helps maintain consistent quality in the final forged parts.

Ensures safety and reliability, especially in critical applications (e.g., automotive, aerospace).

Chemical Composition Analysis

What is the Purpose of Chemical composition Analysis?

Chemical composition inspection is a critical part of the overall inspection process and plays a key role in quality control for raw materials received at a forging plant.

This type of inspection ensures that the material’s elemental composition matches the required chemical specifications for its intended forging application.

The strength, durability, hardness, corrosion resistance, and overall performance of the final forged product are directly influenced by the accuracy of this chemical inspection.

The primary objective of this chemical composition inspection is to verify that the material grade provided by the supplier aligns with recognized standards, such as ASTM, DIN, JIS, or IS specifications.

This inspection targets both major alloying elements—like carbon, manganese, chromium, molybdenum, and nickel—and trace or residual elements, including potentially harmful impurities such as sulfur and phosphorus.

Major elements determine critical mechanical properties like tensile strength, toughness, and heat resistance.

The inspection also ensures that impurity levels remain within acceptable limits to prevent brittleness, cracking, or poor forgeability.

Multiple techniques are employed for this chemical inspection, each chosen based on accuracy needs and material type:

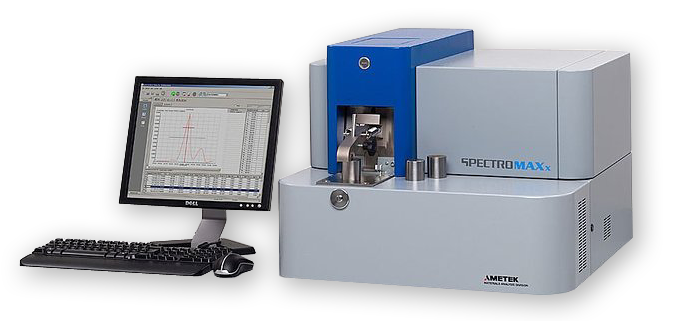

Optical Emission Spectroscopy (OES) is one of the most widely used methods for rapid and precise inspection of metallic samples.

It works by sparking the sample and analyzing the emitted light to determine the elemental composition.

Wet chemical analysis, though more time-intensive, is sometimes used for in-depth inspection or to verify OES results for critical components.

Positive Material Identification (PMI) devices are also employed, particularly in the receiving area, for quick, on-site inspection of alloy types and verification of material certificates.

This inspection step is carried out before the raw material is accepted into production. It serves as a gatekeeper to prevent non-conforming or substandard materials from proceeding to the forging process.

Without proper chemical composition inspection, there is a risk of producing defective or non-compliant forged products, which can lead to mechanical failure, customer rejections, or safety issues.

The process begins with collecting a representative sample from the raw material, either by cutting a small piece or using a test coupon if provided by the supplier. The sample surface is carefully prepared by grinding or polishing to remove any rust, oil, or scale, which can interfere with accurate readings. After the test is performed, the results are recorded and compared to the material specification provided in the purchase order or technical standards. It is also common practice to verify the material’s Mill Test Certificate (MTC) received from the supplier, comparing its data with in-house test results to confirm consistency and compliance.

This step is particularly important in industries where component performance and safety are critical, such as aerospace, automotive, oil and gas, and heavy machinery. If the raw material does not meet the required chemical composition, it can lead to serious defects in the final forged part, resulting in costly rework, delays, or even field failures. Performing thorough chemical analysis not only ensures the material’s suitability for forging but also supports traceability, documentation, and compliance with customer and industry requirements.

What is Analyzed?

Main Elements:

Elements like Carbon (C), Manganese (Mn), Chromium (Cr), Nickel (Ni), Molybdenum (Mo), etc., depending on the alloy or steel grade.

Impurities and Trace Elements:

Sulfur (S), Phosphorus (P), and other unwanted elements are checked to ensure they are within acceptable limits.

Methods Used

Spectrometer Testing:

Optical Emission Spectroscopy (OES) is commonly used for fast and accurate chemical analysis.Wet Chemical Analysis:

Used for more precise or detailed analysis, especially in lab settings.Portable Analyzers (PMI – Positive Material Identification):

Handy for quick checks at the material receiving area, especially for alloy verification.

Why It’s Important:

- Ensures material meets mechanical and chemical standards for forging.

- Prevents wrong or substandard material from entering production.

- Supports traceability and compliance with industry standards (like ASTM, DIN, IS, JIS).

- Critical for safety and performance in high-stress applications.

Process of Chemical Composition Analysis

- In a forging plant, the chemical composition analysis of raw materials is a vital quality control step to ensure the materials meet the required specifications before entering the forging process. The process begins with proper sampling of the raw material, which may be in the form of billets, rods, or ingots. A representative sample is taken from each heat or batch, ensuring that surface contaminants such as oil, rust, or mill scale are removed prior to testing. This is crucial because any contamination can significantly affect the accuracy of the results.

- Once the sample is collected, it undergoes sample preparation, which varies depending on the analysis method. For instance, if Optical Emission Spectroscopy (OES) or X-Ray Fluorescence (XRF) is used, the surface of the metal is ground and polished to create a clean, flat surface for accurate readings. In contrast, if a wet chemistry method or Inductively Coupled Plasma (ICP) analysis is used, the sample may need to be dissolved in acid or other reagents to prepare it for analysis. For carbon and sulfur analysis, combustion methods are typically used.

- The next step is selecting the appropriate analytical technique, based on the type of material and the elements to be measured. Common techniques include OES for fast, multi-elemental analysis of steels and alloys; XRF for non-destructive elemental testing; ICP-OES or ICP-MS for high-precision analysis of trace elements; and combustion analyzers for determining carbon and sulfur content. Calibration of the analytical instruments using certified reference materials (CRMs) is essential before testing to ensure data accuracy and reliability.

- After calibration, the sample is analyzed, and the instrument produces a detailed elemental breakdown. This data is then interpreted and compared against applicable standards—such as ASTM, AISI, or customer-specific requirements—to verify whether the material composition falls within acceptable ranges. A chemical composition report or Mill Test Certificate (MTC) is generated, documenting the actual elemental percentages, material grade, heat number, test method, and other relevant details.

- Finally, the results are reviewed, and a decision is made: if the material complies with the required specifications, it is cleared for forging. If it fails to meet any criteria, it may be rejected, returned to the supplier, or subjected to reprocessing depending on the company’s quality procedures. All analysis records are stored and tracked as part of the quality management system to ensure traceability and accountability.

Mechanical Properties Testing

Common Mechanical Tests

1. Tensile Test

Measures:

Yield Strength

Ultimate Tensile Strength (UTS)

Elongation (%)

Reduction in Area

Equipment: Universal Testing Machine (UTM)

Purpose: Assesses material’s resistance to pulling forces and ductility.

2. Hardness Test

Methods:

Brinell Hardness (BHN)

Rockwell Hardness (HRB, HRC)

Vickers Hardness (VHN)

Purpose: Evaluates resistance to indentation, useful for wear and deformation resistance.

3. Impact Test

Method: Charpy V-Notch Test

Measures: Energy absorbed during fracture (in joules)

Purpose: Determines toughness, especially at low temperatures.

4. Bend Test (if applicable)

Purpose: Assesses ductility and flexibility.

Checks for surface cracks or material brittleness during bending.

5. Fatigue Test (optional, for critical applications)

Purpose: Evaluates material performance under cyclic loading.

Used for materials in dynamic or rotating components.

Testing Process

Sample Preparation:

- Machined test specimens from raw material (as per standards).

- Ensure surface cleanliness and dimensional accuracy.

Test Execution:

Follow standard procedures (ASTM E8 for tensile, ASTM E23 for impact, etc.).

Use calibrated and certified equipment.

Data Recording & Analysis:

- Compare results with material specifications.

- Ensure values fall within acceptable ranges.

Documentation

As part of the process, a Mechanical Properties Test Report should be prepared to record the results of the testing. This report includes important details such as the type and grade of the material, the heat number and batch ID, the results of tests like tensile strength and hardness, and the methods and standards used for testing. It should also mention the date of testing and the name of the technician who performed the tests. This report is then included in the Mill Test Certificate (MTC) or kept as part of the material traceability records, helping ensure that each batch of raw material can be tracked and verified for quality.As part of the quality assurance process in a forging plant, a Mechanical Properties Test Report should be meticulously prepared to document the results of mechanical testing performed on the raw material. This report serves as a formal record and includes essential information such as the type and grade of the material, the heat number, batch or lot identification number, and the results of mechanical tests conducted—typically including tensile strength, yield strength, elongation, hardness, and sometimes impact toughness, depending on the application and standards being followed. It also specifies the testing methods and international or customer-specific standards used (such as ASTM, ISO, or EN), ensuring consistency and compliance. Additionally, the date of testing, name or ID of the technician, and equipment used should be noted to maintain accountability and traceability. This report is then either integrated into the Mill Test Certificate (MTC) or retained as a separate document within the company’s quality and traceability records system. It plays a critical role in verifying that the material not only meets chemical specifications but also possesses the required mechanical properties for safe and effective use in the forging process.

Acceptance Criteria

The acceptance criteria for raw materials in a forging plant are based on the results of mechanical properties testing. If all measured properties—such as tensile strength, hardness, and impact resistance—fall within the specified limits defined by industry standards or customer requirements, the material is approved for forging and released for production. However, if any of the properties fail to meet the required specifications, the material is either rejected outright or subjected to further evaluation. In some cases, non-conforming material may be sent for heat treatment or corrective processing to bring it within acceptable limits. If correction is not feasible, the material may be returned to the supplier. This ensures that only compliant materials proceed to forging, maintaining product integrity and performance.

Nondestructive Testing

Common NDT Methods

1. Visual Testing (VT)

Simple, first-line inspection.

Involves looking for surface defects like cracks, corrosion, or deformation.

Often uses magnifying glasses, mirrors, or cameras.

2. Ultrasonic Testing (UT)

Uses high-frequency sound waves to detect internal flaws.

Sound waves reflect off defects and are picked up by a receiver.

Good for detecting cracks, voids, and thickness variations.

3. Radiographic Testing (RT)

Uses X-rays or gamma rays to view the internal structure.

Produces an image (radiograph) showing any internal defects.

Suitable for welds, castings, and thick materials.

4. Magnetic Particle Testing (MT)

For ferromagnetic materials only (like steel).

Applies magnetic field and iron particles to reveal surface and near-surface cracks.

Defects are visible as particle accumulations.

5. Dye Penetrant Testing (PT)

Applies dye to surface → dye seeps into cracks → excess removed → developer applied.

Cracks become visible as colored lines or spots.

Best for detecting surface-breaking flaws in non-porous materials.

6. Eddy Current Testing (ECT)

Uses electromagnetic induction to detect surface and near-surface flaws.

Effective for conductive materials (e.g., metals).

Can also measure coating thickness and conductivity.

Benefits of NDT

Non-destructive – component remains intact and usable.

Cost-effective for quality control in production.

Allows for early defect detection and preventive maintenance.

Enhances product safety and reliability.

Applications

Used in industries such as:

Forging and manufacturing

Aerospace and automotive

Oil and gas

Power generation

Construction and infrastructure

Metallurgical Testing

Metallurgical testing is a process used to examine the structure and properties of metals and alloys. It helps to determine the quality of the material, understand the causes of any failures, and check whether the material meets required standards. This type of testing can include both destructive methods, where the material is altered or broken during testing, and non-destructive methods, where the material remains intact.

Key Types of Metallurgical Testing

1. Microstructure Examination

This test uses an optical or electron microscope to look at the internal structure of the metal at a very fine level. It helps reveal important features such as grain size, phase distribution, inclusions, and the effects of heat treatment. Understanding the microstructure is key to predicting how a material will perform during manufacturing and in its final application.

2. Macrostructure Examination

Macrostructure examination looks at the larger structure of the metal, usually with the naked eye or at low magnification. This test helps identify surface and internal defects such as cracks, laps, voids, or segregation that may have occurred during casting or forging.

3. Hardness Testing

Hardness testing checks the metal’s resistance to indentation or scratching. It’s a quick way to get an idea of a material’s strength. Common methods include the Brinell, Rockwell, and Vickers tests, each suitable for different types of materials and applications.

4. Tensile Testing

This test measures how strong and ductile a material is by pulling it until it breaks. Key results include yield strength, ultimate tensile strength (UTS), and elongation. These values tell us how much load the material can handle before deforming or failing.

5. Impact Testing

Impact testing is used to find out how tough a material is, especially under sudden or shock loading. The most common method is the Charpy V-notch test, which measures how much energy the material can absorb before it fractures. This is important for parts that may face impacts or low temperatures.

6. Fractography

Fractography involves studying the fracture surfaces of broken metal parts, usually under a microscope. It helps engineers understand why and how a failure happened—whether due to fatigue, brittle fracture, or other issues. This is often used in failure analysis.

7. Chemical Analysis

Chemical analysis determines the elemental composition of the metal. It verifies if the material contains the correct amounts of elements like carbon, manganese, chromium, etc. This test is often paired with microstructure evaluation to confirm the metal meets grade and standard requirements.

Purpose and Benefits

- Confirms material grade and treatment.

- Detects defects, inconsistencies, or heat treatment issues.

- Supports failure analysis and root cause investigations.

- Ensures compliance with manufacturing and industry standards.