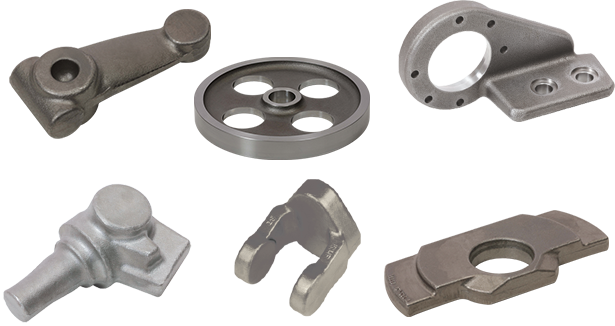

Forging is one of the oldest known metalworking processes, dating back thousands of years to the earliest civilizations. It involves shaping metal through the application of compressive forces, typically using a hammer or a die. Over centuries, forging has evolved from rudimentary blacksmithing to sophisticated, high-precision processes used in modern industry.

Today, forging plays a critical role in manufacturing due to its ability to produce components with exceptional mechanical properties, including superior strength, toughness, and fatigue resistance. These characteristics make forged parts indispensable across a wide range of industries, including automotive, aerospace, oil and gas, construction, agriculture, defense, power generation, marine, and railway sectors. Common forging applications include crankshafts, connecting rods, gears, axles, valves, flanges, turbine components, and structural supports—all essential for ensuring performance, reliability, and safety in demanding environments.

Understanding Forging and Its Types

Before delving into specific industry applications, it is important to understand the basic types of forging processes commonly used today:

Open-Die Forging

Closed-Die Forging (Impression Die Forging)

Cold Forging

Hot Forging

Seamless Rolled Ring Forging, etc

Each forging method is chosen based on material properties, desired mechanical performance, part complexity, and economic considerations.

Know more : Forging, Types of Forging

Automotive Industry

The automotive industry heavily relies on forging applications due to their superior strength, durability, and cost-effectiveness. Forging enhances the mechanical properties of metals by aligning the grain structure along the shape of the part, resulting in improved fatigue resistance and structural integrity. These characteristics are essential in vehicle manufacturing, where safety, performance, and fuel efficiency are top priorities.

Forging applications are widely used across various systems in a vehicle, especially in areas subjected to high stress or repetitive motion. Their ability to withstand extreme loads without failure makes them ideal for critical parts such as crankshafts and connecting rods. For instance, crankshafts made through forging applications can endure the continuous cyclic forces generated during engine operation, ensuring engine reliability and longevity. Connecting rods, also commonly produced through forging applications, are lighter and more resistant to fatigue than cast or machined versions, contributing to better engine performance and reduced weight.

Common forging applications in the automotive sector include:

Crankshafts – Handle high rotational forces in the engine.

Connecting rods – Link pistons to the crankshaft and endure high-speed motion.

Gears and shafts – Transmit torque efficiently in transmissions and drivetrains.

Axles and wheel spindles – Support vehicle weight and transfer motion to wheels.

Steering knuckles – Crucial for handling and suspension systems.

With the rise of electric vehicles (EVs), forging applications have become even more critical. EVs require high-strength forged components in electric motors, drivetrains, and structural frameworks to ensure durability, thermal stability, and crashworthiness. Forged aluminum and high-strength steel, both central to modern forging applications, help reduce vehicle weight and improve overall efficiency—two key factors in EV performance and safety.

Additionally, forging applications offer significant economic advantages in mass production. While initial tooling costs may be higher, the long-term benefits—such as enhanced part reliability, reduced failure rates, and consistent quality—make forging applications a cost-effective manufacturing solution over time.

In conclusion, forging applications remain essential in modern automotive manufacturing. Whether in traditional combustion engines or next-generation electric vehicles, forging applications continue to drive innovation, enhancing vehicle safety, performance, and efficiency at every level.

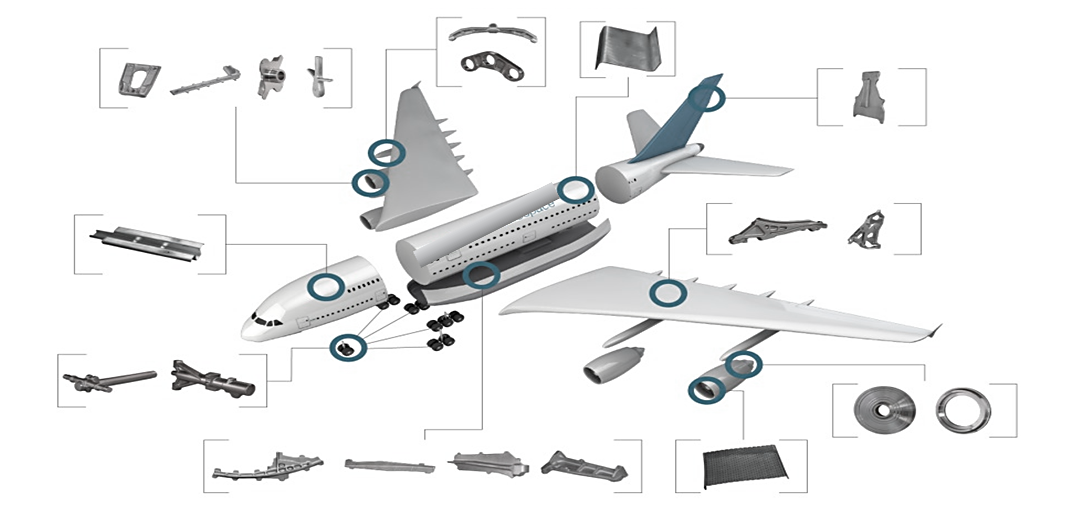

Aerospace Industry

The aerospace industry is one of the most demanding sectors in terms of material performance, safety, and precision. Forging applications play a crucial role in meeting these requirements by producing components with superior mechanical strength, reliability, and resistance to extreme conditions. Because aircraft and spacecraft operate under intense stress, temperature fluctuations, and fatigue, forging applications are essential to ensure long-term durability and structural integrity.

Forging applications are extensively used in both commercial and military aerospace systems. These parts must be lightweight yet strong to support flight efficiency and safety. The forging process refines the grain structure of metals, significantly enhancing the strength-to-weight ratio—an especially critical advantage of forging applications in aerospace design, where every kilogram impacts fuel consumption and payload capacity.

Common forging applications in aerospace include:

Landing gear components – Must withstand high impact forces during takeoff and landing.

Turbine discs and blades – Exposed to extreme heat and pressure inside jet engines.

Structural airframe parts – Provide support and stability to the aircraft body.

Engine mounts and brackets – Secure the engine to the airframe and absorb vibration.

Wing spars and ribs – Load-bearing components that maintain wing integrity.

In aerospace, both aluminum and titanium alloys are widely used in forging applications. Aluminum is valued for its lightweight properties and solid structural performance, while titanium is the material of choice for high-performance forging applications due to its outstanding strength, heat tolerance, and corrosion resistance.

The grain alignment achieved through forging applications contributes to increased resistance to cracking, fatigue, and impact. This makes forging applications ideal for mission-critical aerospace components where failure is not an option. Furthermore, forging applications allow for tighter tolerances and improved material consistency compared to casting or machining, helping reduce potential flaws and defects.

While aerospace forging applications require high precision and strict quality control, the long-term benefits far outweigh the initial costs. Reduced part failure, improved strength-to-weight efficiency, and extended service intervals all contribute to the enhanced reliability and performance of modern aircraft.

In conclusion, forging applications are vital to the aerospace industry. From engine parts to structural components, forging applications ensure that aerospace systems meet the rigorous demands of flight, delivering unmatched strength, safety, and efficiency for both current and next-generation aircraft.

Oil and Gas Industry

The oil and gas industry operates in some of the harshest environments, requiring equipment that can withstand high pressure, corrosive substances, and extreme temperature variations. Forging applications are crucial in meeting these challenges, offering the strength, durability, and reliability needed for safe and efficient operations. From deep-sea drilling rigs to high-pressure pipeline systems, forging applications are used extensively across all stages of oil and gas exploration, extraction, processing, and transportation.

Forging applications enhance the mechanical properties of metals by aligning the grain structure, resulting in components that are tougher and more resistant to fatigue, corrosion, and cracking. This grain refinement is vital in oil and gas environments, where the integrity of every component can determine the safety and success of the operation. In such high-stakes scenarios, forging applications provide a dependable solution that significantly reduces the risk of failure.

Common forging applications in the oil and gas industry include:

Drill bits and heads – Designed to cut through rock formations during exploration and drilling.

Flanges and pipe connectors – Provide secure, leak-resistant joints in pipeline systems.

Valve bodies – Regulate flow and pressure in processing and transportation systems.

High-pressure vessels – Contain and control fluids under extreme conditions.

Subsea equipment – Used in underwater drilling and production operations.

Many forging applications are essential in creating pressure-retaining and load-bearing parts. For instance, forged flanges ensure superior structural integrity and significantly lower the risk of leaks—an absolute necessity in maintaining safe and efficient pipeline operations. Similarly, forging applications like drill collars and subs are engineered to withstand high mechanical stress, impact loads, and continuous vibration during deep drilling.

Another major advantage of forging applications in the oil and gas sector is their role in reducing maintenance demands and unplanned downtime. Forged parts offer exceptional wear resistance and a longer service life, which minimizes operational disruptions and costly repairs. In turn, this contributes to greater economic efficiency and enhances environmental protection by reducing the chances of leaks or catastrophic equipment failures.

From upstream drilling to downstream processing, forging applications support the entire value chain of the oil and gas industry. Whether on offshore rigs, in refineries, or across vast pipeline networks, these components deliver unmatched performance under extreme conditions.

In conclusion, the oil and gas sector depends heavily on forging applications to ensure performance, reliability, and safety in some of the world’s most demanding environments. Through enhanced strength, superior fatigue resistance, and operational longevity, forging applications play an indispensable role in driving safe, efficient, and sustainable energy operations.

Agricultural Equipment

The agricultural industry operates in a wide range of demanding environments—from rocky, uneven terrains to abrasive, dust-filled fields—and must contend with heavy loads, repeated impact, and continuous use. Agricultural equipment requires components that can endure these rigorous conditions while delivering consistent performance. Forging applications play a vital role in meeting these challenges, offering the strength, durability, and reliability essential for efficient and long-lasting farming operations. From tractors and plows to harvesters and seeders, forging applications are extensively utilized across all stages of modern agricultural production.

Forging applications significantly enhance the mechanical properties of metals by refining grain structure, resulting in components that are tougher and more resistant to wear, impact, and fatigue. This grain alignment is particularly important in agricultural settings, where machinery operates for extended hours under harsh outdoor conditions. Equipment failure during crucial planting or harvesting periods can lead to costly delays and yield losses, making the reliability of forging applications indispensable.

Common forging applications in agricultural machinery include:

Plowshares and tillage blades – Engineered to cut through soil, roots, and rocks while maintaining sharpness and structural integrity.

Axles and shafts – Transfer power and bear heavy loads, ensuring efficient motion and torque across rough terrains.

Gear components and drive systems – Crucial for controlling speed and torque in tractors and harvesters.

Connecting rods and crankshafts – Found in internal combustion engines, they withstand high pressures and repetitive motion.

Hitch components and couplers – Provide secure, load-bearing connections between implements and towing vehicles.

Many of these forging applications are specifically designed for high-stress and wear-intensive uses. For instance, forged tillage tools retain sharp edges and resist fractures better than cast alternatives, even in abrasive soil conditions. Similarly, forging applications in gear systems provide enhanced fatigue strength, ensuring smoother operation and fewer breakdowns over long periods.

By utilizing forging applications, agricultural machinery benefits from reduced maintenance needs and increased operational uptime. The superior wear resistance and mechanical strength of forged parts lead to longer service life, minimizing the frequency of replacements and downtime during peak seasons. This directly contributes to improved productivity and efficiency in farm operations.

Furthermore, forging applications support sustainable farming practices. Their long-term durability helps reduce material waste and resource consumption by extending the lifespan of equipment components and limiting the need for frequent part replacements.

In conclusion, the agricultural industry relies heavily on forging applications to ensure durability, reliability, and efficiency under challenging field conditions. With their superior mechanical properties and long-lasting performance, forging applications are critical to powering modern, high-efficiency farming operations—supporting both economic performance and sustainable agricultural growth.

Construction and Mining

Heavy equipment used in construction and mining operates under some of the most extreme conditions, including abrasive materials, high impact forces, and continuous, long-duration use. In such demanding environments, forging applications are essential for ensuring that machinery remains durable, reliable, and efficient. By imparting superior mechanical properties to metal parts, forging applications make components ideally suited for withstanding the stress and wear typical of heavy-duty operations.

Forging applications are specifically designed to endure shock loads, resist wear, and perform reliably over extended periods. The forging process improves the internal grain structure of metals, resulting in enhanced toughness, fatigue resistance, and structural integrity. These benefits are critical for construction and mining equipment, where the failure of a single component can lead to costly downtime and significant project delays.

Common forging applications in construction and mining include:

Hydraulic cylinders and pistons – Critical for heavy lifting and movement in machinery.

Track links and chains – Used in tracked vehicles and must resist wear from abrasive terrain.

Crusher hammers and picks – Subjected to constant impact and abrasion in crushing equipment.

Drill rods and adapters – Handle repeated high-force drilling in rock and soil.

Loader and excavator arms – Experience high mechanical loads during operation.

Many of these forging applications are tailored for high-wear and impact-prone conditions. For example, forged crusher hammers demonstrate superior resistance to chipping and cracking, significantly outlasting their cast counterparts. Similarly, forging applications like track links maintain structural integrity and wear resistance even in the most rugged terrains, reducing the need for frequent maintenance.

The impact of reliable forging applications extends directly to productivity and safety. When heavy machinery operates with minimal breakdowns, projects remain on schedule, and equipment operators face fewer hazards due to mechanical failure. In high-demand sectors like construction and mining, the longevity and performance of forging applications contribute to smoother operations and lower overall operating costs.

Additionally, forging applications support equipment longevity and reduce the environmental footprint by decreasing the frequency of part replacements. This leads to more sustainable operations, aligning with modern industry goals for efficiency and environmental responsibility.

In conclusion, the use of forging applications in heavy equipment is critical to meeting the intense demands of construction and mining industries. Their superior strength, exceptional wear resistance, and extended service life help minimize downtime, enhance safety, and maximize productivity—making forging applications a foundational element of heavy-duty equipment performance.

Marine Industry

The marine industry operates in highly corrosive, high-moisture environments, often under conditions of extreme pressure, vibration, and mechanical stress. Marine vessels and offshore structures require equipment that can withstand these challenging conditions while maintaining performance and safety. Forged components are essential in meeting these demands, offering the strength, corrosion resistance, and structural integrity necessary for reliable and long-term operation. From cargo ships and naval vessels to offshore platforms and underwater systems, forged parts are used extensively across all segments of the marine sector.

Forging improves the mechanical properties of metals by refining the grain structure, resulting in components that are stronger, tougher, and more resistant to fatigue, corrosion, and impact. This is particularly critical in marine applications, where components are constantly exposed to saltwater, high humidity, and dynamic loads. Equipment failure in marine environments can lead to severe operational disruptions, safety hazards, and costly repairs, making the reliability of forged components vital.

Common forged components in the marine industry include:

- Propeller shafts and rudder stocks – Transmit power and steer vessels, requiring high strength and resistance to torsion and corrosion.

- Anchor shackles and mooring components – Secure vessels in place, often under extreme tension and environmental exposure.

- Crankshafts and connecting rods – Found in ship engines, they endure high mechanical loads and continuous operation.

- Flanges and fittings – Ensure secure, leak-proof connections in shipboard piping and hydraulic systems.

- Winch and capstan drums – Handle high loads in anchor and cargo handling systems.

Forging is particularly advantageous for producing critical load-bearing and rotating components. For example, forged propeller shafts deliver superior strength and resistance to torsional stresses, ensuring smooth and reliable propulsion. Similarly, forged crankshafts provide exceptional durability and fatigue resistance, supporting efficient engine operation over long voyages and extended service cycles.

The use of forged components also reduces the frequency of maintenance and extends service life, especially in saltwater environments where corrosion can rapidly degrade lesser materials. Their robustness leads to fewer failures, lower repair costs, and greater vessel availability, all of which are crucial for maintaining profitability and safety in marine operations.

In conclusion, the marine industry depends heavily on forged components to withstand harsh sea conditions and ensure operational reliability. Forging offers the mechanical strength, corrosion resistance, and longevity required to support safe, efficient, and sustainable marine transport and offshore activities in some of the world’s most demanding environments.

Railways

The railway industry operates under intense mechanical loads, continuous vibration, and varying weather conditions, demanding components that offer exceptional strength, wear resistance, and reliability. Railway systems—ranging from high-speed passenger trains to heavy freight locomotives—require durable equipment capable of performing safely and efficiently over long distances and extended service intervals. Forged components play a vital role in fulfilling these requirements, providing the toughness, fatigue strength, and dimensional integrity essential for railway operations. From wheels and axles to couplers and suspension systems, forged parts are widely used throughout rail transport infrastructure and rolling stock.

Forging enhances the mechanical properties of metals by aligning and refining the grain structure, producing components that are stronger, more impact-resistant, and better able to withstand fatigue and deformation. This is particularly important in railway applications, where parts must endure constant stress, shock loading, and harsh environmental exposure without failure. Component reliability directly affects safety, performance, and maintenance costs—making forged parts a cornerstone of modern rail engineering.

Common forged components in the railway industry include:

- Railway wheels and axles – Subjected to heavy loads, high speeds, and dynamic forces, requiring high fatigue and impact resistance.

- Couplers and draft gears – Transfer tensile and compressive forces between cars, demanding superior strength and durability.

- Crankshafts and connecting rods – Found in diesel locomotive engines, built to endure extreme mechanical stress.

- Suspension components (like springs and links) – Absorb shocks and vibrations to ensure ride comfort and track stability.

- Brake system components – Require consistent performance under repetitive thermal and mechanical stress during braking.

Forging is especially beneficial in producing safety-critical and load-bearing components. For example, forged railway wheels and axles provide unmatched durability and resistance to surface defects, reducing the risk of catastrophic failure during high-speed or long-haul operation. Likewise, forged couplers are able to absorb high impact loads and repetitive stress, ensuring secure and safe connections between railcars.

The use of forged components also helps minimize maintenance demands and extend the operational life of rolling stock. Their inherent toughness and resistance to crack propagation reduce the frequency of part replacement and service interruptions, which is essential for maximizing uptime and cost-efficiency in rail transport.

In conclusion, the railway industry relies heavily on forged components to ensure safe, durable, and efficient operation under demanding conditions. Forging delivers the mechanical performance, structural integrity, and long-term reliability necessary to support the high standards of safety, speed, and sustainability required in modern rail systems.

Defense and Military

The defense and military industry operates in some of the most demanding and high-risk environments, requiring equipment that performs reliably under extreme conditions such as intense heat, shock, vibration, and exposure to harsh climates. Whether on land, at sea, or in the air, military operations depend on components that offer maximum strength, resilience, and dependability. Forged components are critical in meeting these requirements, providing the durability, toughness, and structural integrity needed for mission-critical systems. From armored vehicles and aircraft to naval ships and missile systems, forged parts are extensively used across the entire defense sector.

Forging enhances the mechanical properties of metals by refining the internal grain structure, resulting in components that are stronger, more resistant to fatigue, and better able to absorb impact without failure. In military applications, where equipment must function without compromise in life-or-death scenarios, the superior reliability of forged parts is essential. Component failure is not an option—it can lead to mission failure, equipment loss, or even loss of life.

Common forged components in the defense and military industry include:

- Armor and vehicle chassis components – Provide protection and structural support in tanks, personnel carriers, and combat vehicles.

- Gun barrels and breech mechanisms – Require high strength, precision, and heat resistance for accurate and reliable firing.

- Aircraft landing gear and structural parts – Must endure high loads and repeated stress during takeoff, landing, and combat maneuvers.

- Missile and rocket components – Require extreme strength and reliability to perform under high pressure and speed.

- Naval components such as shafts and propellers – Must resist corrosion and mechanical stress in marine combat environments.

Forging is especially valuable for producing high-strength, high-reliability parts that are exposed to shock, impact, and heavy loading. For example, forged gun barrels offer superior fatigue resistance and dimensional stability under rapid, high-temperature firing conditions. Similarly, forged landing gear components in military aircraft deliver unmatched toughness and structural integrity, ensuring safe operation under the most extreme landing forces.

The use of forged components also enhances mission readiness and reduces maintenance requirements. Their long service life, resistance to failure, and reduced wear lower the frequency of part replacement and minimize downtime—crucial advantages in combat and field operations where equipment availability and performance are paramount.

In conclusion, the defense and military sector relies heavily on forged components to maintain operational superiority, safety, and reliability in extreme environments. Forging delivers the mechanical strength, impact resistance, and long-term durability essential to support modern defense systems and ensure success in the most challenging and critical missions.

Industrial Machinery

The industrial machinery sector operates in high-demand environments that involve heavy loads, continuous operation, high temperatures, and exposure to abrasive materials and harsh chemicals. Equipment in this sector must perform with precision, efficiency, and durability to support manufacturing, construction, mining, and other essential industries. Forged components are vital in meeting these requirements, offering superior strength, resistance to fatigue and wear, and long-term reliability. From hydraulic presses and gear systems to cranes and compressors, forged parts are integral to the performance and longevity of industrial machinery.

Forging significantly enhances the mechanical properties of metals by aligning the grain structure, resulting in components that are tougher, stronger, and more resistant to cracking and deformation. This is especially important in industrial applications, where even a single equipment failure can halt production, damage assets, and result in significant financial losses. Forged components are engineered to withstand repetitive stress, dynamic loads, and extreme conditions over extended periods of operation.

Common forged components in industrial machinery include:

- Gears and gear shafts – Transfer power and torque under continuous stress in gearboxes and drive systems.

- Crankshafts and connecting rods – Found in industrial engines and compressors, designed to withstand repetitive motion and high mechanical loads.

- Hydraulic cylinder components – Operate under high pressure in presses, lifts, and heavy machinery.

- Press and die components – Require exceptional toughness and wear resistance for shaping and forming operations.

- Couplings and flanges – Ensure secure, high-strength connections in piping and power transmission systems.

Forging is particularly valuable in producing high-strength, wear-resistant components used in critical load-bearing and motion-transfer applications. For instance, forged gear components maintain their shape and structural integrity under extreme torque and load cycles, minimizing the risk of breakdowns in production machinery. Likewise, forged crankshafts are built to endure high-cycle fatigue, making them essential for large-scale industrial engines operating around the clock.

The use of forged components also leads to reduced maintenance and extended equipment service life. Their high resistance to wear, deformation, and failure ensures fewer unplanned shutdowns and lower long-term operating costs. This reliability is crucial in industrial settings where efficiency, uptime, and safety are top priorities.

In conclusion, the industrial machinery sector depends on forged components to deliver performance, strength, and longevity under demanding operational conditions. Forging provides the mechanical integrity, durability, and precision required to support high-output, high-reliability industrial operations across the globe.