Machine Shop Tools

A well-equipped machine shop is the backbone of manufacturing and fabrication processes. Whether you’re running a small workshop or managing a large industrial facility, having the right tools is essential for accuracy, productivity, and safety. A fully functional machine shop is a dynamic space where raw materials are transformed into finished parts using a variety of processes, including cutting, drilling, milling, and grinding.

To perform these tasks effectively, a machine shop requires an extensive collection of tools and equipment, ranging from precise measuring instruments to powerful machines and versatile hand tools. These tools ensure that every component is crafted to exact specifications and tolerances, reducing errors and improving overall quality.

Below is a detailed breakdown of the essential categories of tools every machine shop should have, including their functions and importance in day-to-day operations.

1. Measuring Tools :

Precision measurement is at the core of machining. Even the most advanced machine is only as effective as the tools used to measure the results. Proper measuring instruments help machinists confirm that each part meets the required specifications and tolerances.

Calipers

Calipers are versatile instruments used to measure the internal and external dimensions of a part, as well as depths and step distances. They come in several types, including digital, dial, and vernier calipers. Digital calipers are especially popular due to their ease of reading and quick conversion between metric and imperial units.

Micrometers

Micrometers offer more precise measurements than calipers and are ideal for critical dimensions. Available in outside, inside, and depth versions, micrometers are used when tolerances are tight, such as when measuring shaft diameters or hole sizes in components requiring high accuracy.

Dial Indicators

Dial indicators are used to measure very small deviations in surface flatness or part alignment. They are essential when setting up workpieces in machines or checking the runout of rotating components.

Edge Finders

Edge finders help machinists locate the precise edges of a workpiece during setup on milling machines. Accurate edge location is vital for part accuracy, especially in complex machining operations.

Center Punch

The center punch is a simple yet vital tool used to mark the center of holes before drilling. It prevents drill bits from wandering and ensures clean, accurate holes.

Combination Square Set

This multi-functional tool combines a ruler, square, and protractor. It is used for layout work, marking, and checking angles and flatness. Its versatility makes it a staple in every machinist’s toolbox.

Feeler Gauges

Feeler gauges are used to measure the gap or clearance between two surfaces. This is especially important when setting up machines or checking tolerances during assembly.

Protractor

Protractors help in measuring and marking precise angles. While simple, they are useful for layout work, especially on angled surfaces or components.

Tape Measure

The tape measure is a general-purpose tool used for layout and rough measurements. Though not used for fine tolerances, it’s invaluable for initial planning and setup.

2. Machines :

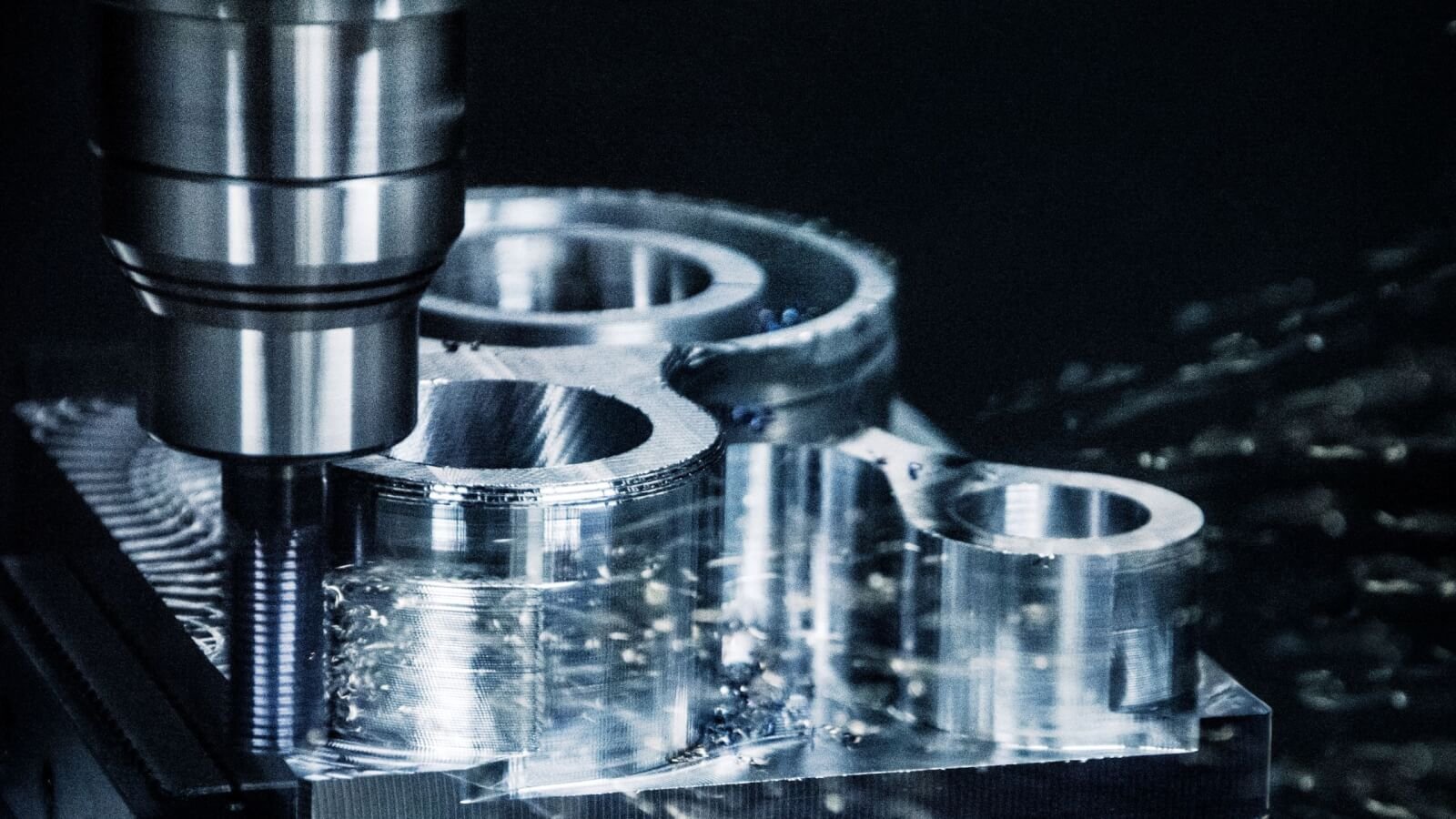

While hand tools and measuring instruments provide support, machines perform the actual material removal processes. Each machine is designed for specific operations such as turning, milling, drilling, and grinding. Having the right machines ensures versatility and efficiency in handling different projects.

Lathes

The lathe is one of the oldest and most versatile machine tools in a shop. It is used to rotate workpieces against a cutting tool to perform operations like turning, facing, threading, and knurling. Lathes are essential for producing cylindrical components such as shafts, bushings, and pulleys.

Modern CNC lathes offer programmable control, allowing for more complex and repeatable machining operations with higher efficiency and accuracy.

Milling Machines

Milling machines remove material using rotating cutting tools. They are used to create flat surfaces, slots, holes, and complex 3D shapes. Vertical and horizontal milling machines can accommodate a wide variety of setups and tooling.

CNC milling machines are widely used in modern shops for producing intricate parts with high accuracy and repeatability. Their ability to work in multiple axes makes them suitable for complex machining tasks.

Drill Presses

Drill presses are designed specifically for creating holes in metal, plastic, or wood. Unlike handheld drills, drill presses provide more control and accuracy, especially when drilling through tough materials or performing repetitive drilling tasks.

They can be equipped with various drill bits, countersinks, and reamers depending on the application.

Grinding Machines

Grinding machines are used for fine finishing and high-precision material removal. They can smooth surfaces, sharpen tools, or bring components to exact dimensions. Surface grinders and cylindrical grinders are common in tool rooms and precision shops.

Grinding is especially important for tools and dies, where high surface quality and dimensional accuracy are critical.

Bandsaw

The bandsaw is used for cutting raw stock into manageable pieces. It can cut through a wide range of materials, including metal bars, tubes, and sheet stock. Horizontal bandsaws are typically used for straight cuts, while vertical bandsaws offer more flexibility for curved and angled cuts.

3. Cutting and Shaping Tools :

In any machine shop, cutting and shaping tools play a crucial role in transforming raw materials into precise, finished parts. These tools are used with machines such as lathes, milling machines, and drill presses to remove excess material and create the desired shapes and features. The right cutting tools not only improve machining efficiency but also enhance surface finish and extend the life of machines and tooling. Let’s explore the essential cutting and shaping tools that every machinist relies on.

Drill Bits

Drill bits are among the most common cutting tools and come in a wide range of shapes and sizes tailored to different applications. The most familiar type is the twist drill bit, which is used to create cylindrical holes in a variety of materials. There are also specialized types such as step drills, which create holes of varying diameters in a single operation, and spade bits, used primarily for larger holes in softer materials.

The choice of drill bit material is critical. High-Speed Steel (HSS) bits are standard for general-purpose drilling, while cobalt bits offer greater heat resistance and durability, ideal for harder metals. Carbide bits are the most wear-resistant and are used for demanding applications where precision and longevity are paramount.

End Mills

End mills are specialized cutting tools used primarily in milling machines. Unlike drill bits that cut straight down, end mills cut laterally, allowing the creation of slots, contours, and complex 3D shapes. End mills come in various profiles, including flat end mills for sharp corners and flat-bottomed slots, ball nose end mills for rounded contours, and corner radius end mills that reduce stress concentration by adding a radius to corners.

These tools can be made from HSS, carbide, or coated materials to enhance wear resistance and performance. End mills are essential for detailed machining tasks such as mold making, aerospace parts, and intricate component shaping.

Reamers

Reamers are precision tools used to finish drilled holes to very accurate dimensions and smooth surface finishes. Unlike drill bits, which remove material to create holes, reamers slightly enlarge holes and improve their roundness and finish. They are ideal when a hole requires a precise diameter, often for press-fit applications where tight tolerances are critical.

Reamers are typically made of HSS or carbide and come in several types including straight-fluted and spiral-fluted varieties, each suited for different materials and hole qualities.

Lathe Cutting Tools

In lathe operations, cutting tools are mounted on tool holders to perform various shaping functions such as turning, facing, grooving, and threading. These tools are often made from carbide inserts, ceramic, or HSS, depending on the material being machined and the required cutting speeds.

The geometry of lathe tools varies widely to optimize cutting performance. For example, threading tools have sharp, precise edges for cutting screw threads, while grooving tools have a profile designed to create narrow slots. Choosing the correct insert and tool holder is critical for achieving desired surface finish and tool longevity.

Deburring Tools

Machined parts often have sharp edges or small metal fragments called burrs, which need to be removed to ensure safety and dimensional accuracy. Deburring tools are specially designed to remove these imperfections efficiently. Using the right deburring tool improves the quality of the finished product and prepares parts for assembly or coating.

Files and Burr Whippets

Files are traditional hand tools used to manually smooth and shape rough edges or surfaces. They come in various shapes and coarseness levels to match specific finishing needs.

For faster and more consistent deburring, burr whippets—rotary tools equipped with abrasive bits—are used. Powered by air or electricity, they are especially effective for cleaning up drilled holes, internal features, and complex contours that are difficult to reach with hand tools.

Hand Tools :

In any machine shop, hand tools are fundamental to daily operations. Though they might seem simple compared to large machines, hand tools are indispensable for setup, adjustment, assembly, and finishing tasks. They provide the precision and control necessary for intricate work and enable machinists to perform quick fixes and fine-tuning with ease. Here’s a look at some of the most essential hand tools that every machinist should have in their toolkit.

Allen Wrench Set (Hex Keys)

Allen wrenches, also known as hex keys, are one of the most commonly used hand tools in a machine shop. These L-shaped tools fit hexagonal socket screws and bolts, which are prevalent in machinery and tooling assemblies. Their simple design allows machinists to tighten or loosen fasteners in tight spaces where traditional wrenches can’t reach. Allen wrenches come in various sizes to match different screw heads and are indispensable for machine setup, maintenance, and repair.

Adjustable Wrenches (Crescent Wrenches)

Adjustable wrenches, often called crescent wrenches, are versatile tools capable of gripping a wide range of bolt and nut sizes. Their adjustable jaw allows machinists to use one wrench for multiple fasteners, making them ideal for machine assembly and adjustments. These wrenches are particularly helpful during tool changes or when specific fixed-size wrenches are unavailable, offering flexibility and convenience on the shop floor.

Tap Handle

A tap handle is a specialized tool used for manual threading operations. It holds taps, which are cutting tools designed to create internal threads in pre-drilled holes. Using a tap handle gives the machinist control and precision, allowing for clean, accurate threads. It also ensures the tap stays aligned, reducing the risk of cross-threading or damaging the workpiece. Tap handles come in various sizes to accommodate different tap shank diameters.

Dead-Blow Hammer

The dead-blow hammer is a valuable tool for applying controlled force without causing damage. Unlike traditional hammers, it contains a sand or shot-filled head that absorbs impact shock and prevents rebound. This feature makes it ideal for aligning machine parts, seating components, or driving pieces into place gently. Using a dead-blow hammer minimizes the risk of marring delicate surfaces and improves assembly accuracy.

Calculator

Though it may seem out of place among physical tools, a calculator is essential for machinists. It aids in quick calculations related to machining parameters such as cutting speeds, feed rates, tool paths, and dimensional conversions. Accurate calculations are vital to prevent mistakes and optimize machining efficiency. Many machinists prefer handheld calculators for convenience during setups and programming.

Taps and Dies

Taps and dies are cutting tools used to create or repair threads on metal parts. Taps cut internal threads inside holes, allowing bolts or screws to fit securely. Dies, on the other hand, cut external threads on rods or shafts. Having a complete set of taps and dies enables machinists to fabricate custom threaded parts, fix damaged threads, or prepare components for assembly. Proper use of these tools ensures mechanical reliability and part compatibility.

Rivets and Riveting Gun

Rivets provide a strong, permanent method for joining sheet metal or other materials, especially when welding or screws aren’t feasible. They are widely used in fabrication and repair work to fasten components securely without requiring access to both sides of the joint. A riveting gun simplifies this process by delivering consistent force, speeding up production and ensuring strong, reliable connections. This tool is essential in many manufacturing and maintenance scenarios.

Other Important Equipment in a Machine Shop

While measuring tools, machines, cutting tools, and hand tools form the core of any machine shop, several other pieces of equipment play vital roles in ensuring smooth and efficient operations. These additional tools and utilities, though sometimes overlooked, contribute significantly to the shop’s overall productivity, safety, and maintenance. In this section, we’ll explore some of the most important supplementary equipment: air compressors, welding machines, and cleaning supplies.

Air Compressor

An air compressor is an essential piece of equipment in nearly every modern machine shop. Its primary function is to generate and supply compressed air, which powers a wide variety of pneumatic tools. Pneumatic tools are favored in many workshops because they are lightweight, powerful, and typically more durable than their electric counterparts.

Common pneumatic tools powered by compressed air include impact wrenches, nail guns, spray guns, and air ratchets. These tools make assembly, disassembly, and finishing tasks quicker and easier, significantly improving workflow and reducing operator fatigue.

Besides powering tools, compressed air is also invaluable for cleaning. Machinists often use air blowers or air hoses to remove chips, dust, and coolant from machines, work surfaces, and intricate parts. This helps maintain a clean environment and prevents debris from interfering with machine accuracy or damaging sensitive components.

Air compressors can vary in size and capacity, from small portable units suitable for occasional use to large stationary systems that serve an entire shop. Depending on the size of your operation, investing in a reliable air compressor system can enhance tool versatility and overall shop efficiency.

Welding Machine

Although welding is technically a separate process from machining, it is often indispensable in machine shops, particularly when fabrication or repair work is involved. Machinists and fabricators frequently need to join metal components, build custom fixtures, or fix broken parts. A reliable welding machine allows the shop to handle these tasks in-house without relying on external vendors.

There are several types of welding machines commonly found in machine shops:

MIG (Metal Inert Gas) Welders: MIG welding is widely used because it is versatile, easy to learn, and provides clean, strong welds. It uses a continuously fed wire electrode and shielding gas to protect the weld from contamination.

TIG (Tungsten Inert Gas) Welders: TIG welding offers greater precision and is ideal for welding thin or exotic metals. It requires more skill but produces very high-quality, aesthetically pleasing welds.

Stick Welders: Stick welding is a more traditional method and is useful for thicker materials or outdoor work where shielding gas is not practical.

By having welding capabilities onsite, a machine shop can quickly adapt to various projects and repair needs, saving time and reducing costs.

Cleaning Supplies

A clean and organized workspace is crucial for maintaining safety, efficiency, and quality in any machine shop. Accumulated dirt, metal shavings, and coolant residue can cause accidents, machine malfunctions, and inaccurate measurements. Therefore, cleaning supplies are a critical yet often underappreciated component of shop equipment.

Common cleaning essentials include:

Rags and Wipes: For wiping down machines, tools, and work surfaces.

Degreasers and Solvents: Used to remove oil, grease, and tough residues from metal parts and machinery.

Coolant Recovery Tools: Coolants are widely used to cool cutting tools and workpieces during machining. Proper management of coolant through filtering and recycling systems extends its life and keeps the shop environment cleaner.

Brushes and Scrapers: For removing chips and debris from tight spaces and machine components.

Regular cleaning routines not only prolong the life of expensive equipment but also create a safer working environment by reducing slips, trips, and respiratory hazards from dust or chemical fumes.

Related posts:

- Machining and Types of Machining.

- CNC Machining: 5 Powerful Benefits, How It Works, and Key Applications

- 5-Axis Machining vs 3-Axis Machining – Essential Differences, Applications & Limitations

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses

- 3D Printing vs Machining: Powerful Comparison of Benefits, Limitations, and Applications