Difference Between MIG and TIG Welding

| Feature / Aspect | MIG Welding (GMAW) | TIG Welding (GTAW) |

|---|---|---|

| Full Name | Gas Metal Arc Welding (GMAW) | Gas Tungsten Arc Welding (GTAW) |

| Electrode Type | Consumable wire electrode | Non-consumable tungsten electrode |

| Filler Material | Continuously fed wire | Manually fed filler rod (optional) |

| Shielding Gas | Usually argon + CO₂ or pure argon | Typically pure argon |

| Precision & Control | Moderate | Very high – excellent for intricate work |

| Ease of Use | Easier to learn; beginner-friendly | More difficult; requires more skill and coordination |

| Speed | Faster, suitable for high-production environments | Slower, focused on quality over speed |

| Appearance of Welds | Fair to good; may require cleanup | Excellent; clean and smooth with minimal or no cleanup |

| Spatter / Slag | Can produce spatter | Minimal to none |

| Applications | Automotive, construction, manufacturing | Aerospace, piping, art, high-end fabrication |

| Material Suitability | Best for thicker materials; steel, stainless steel, aluminum | Best for thin or sensitive materials; aluminum, magnesium, stainless steel |

| Equipment Cost | Generally lower | Higher due to specialized torches and accessories |

| Skill Requirement | Lower – more forgiving | Higher – demands steady hands and foot control (pedal) |

| Portability | More portable; widely used in field work | Less portable; used more in controlled environments |

Detailed Explanation

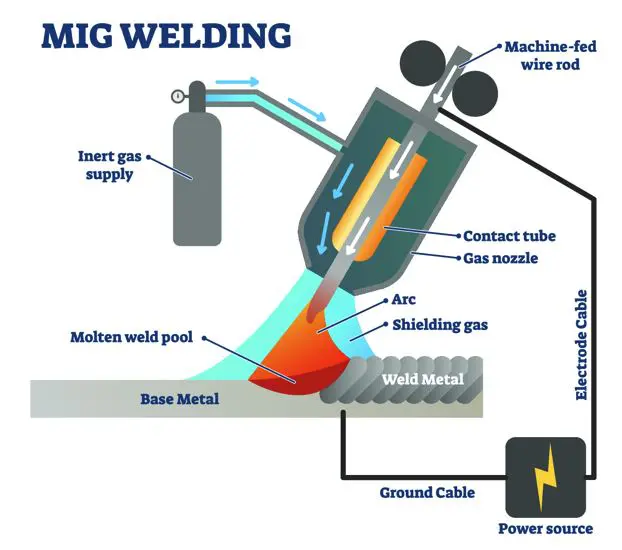

MIG Welding (Metal Inert Gas Welding)

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a widely used welding process that involves the use of a continuously fed consumable wire electrode and a shielding gas. The process is known for its speed, efficiency, and ease of use, making it a popular choice in various industries such as automotive repair, construction, and manufacturing.

At the core of MIG welding is the concept of creating an electric arc between the wire electrode and the base metal. This arc generates heat that melts both the wire and the base material, allowing them to fuse together to form a strong weld joint. The wire serves a dual purpose: it acts as the electrode to conduct electricity and as the filler material to complete the joint.

One of the key advantages of MIG welding is its user-friendly nature. It is considered relatively easy to learn compared to other welding techniques, such as TIG (Tungsten Inert Gas) welding. The semi-automated setup with a wire-feed mechanism allows for consistent and continuous welding, which is especially helpful for beginners or those working on general-purpose projects.

Speed is another major benefit of MIG welding. The continuous feed of the wire electrode significantly reduces the time required to stop and start the welding process, unlike stick welding or TIG welding. This makes MIG welding an efficient choice for large-scale industrial projects, where productivity and time management are critical.

In terms of applications, MIG welding is incredibly versatile. It is commonly employed in automotive repair, especially for bodywork and structural components. In construction and fabrication, it is used to assemble steel frameworks, machinery parts, and metal furniture. In manufacturing, MIG welding is favored for mass production due to its compatibility with automation and robotic welding systems.

MIG welding can be used on a variety of materials, including carbon steel, stainless steel, and aluminum. It performs especially well on thicker sections of metal, making it a go-to method for heavy-duty fabrication. However, the correct type of wire and shielding gas must be chosen depending on the metal being welded. For instance, aluminum typically requires pure argon gas and a softer wire feed system to ensure a clean and strong weld.

The shielding gas is crucial in protecting the molten weld pool from atmospheric contamination, which can lead to porosity, oxidation, or weak welds. A common shielding gas mixture is argon and carbon dioxide (CO₂), which balances arc stability and penetration. For non-ferrous metals like aluminum, pure argon is preferred due to its inert properties.

In conclusion, MIG welding is a highly efficient, versatile, and accessible welding technique. Its ease of use, speed, and adaptability across different materials and industries make it a vital tool for both professional welders and hobbyists alike.

Advantages of MIG Welding

Easy to Learn and Use: MIG (Metal Inert Gas) welding is known for its simplicity, making it an excellent choice for beginners. The process is relatively straightforward compared to other welding methods, allowing new welders to get started with minimal training.

Faster Welding Process: The continuous wire feed in MIG welding ensures a smooth and consistent arc, which significantly increases the welding speed. This results in faster project completion times, especially when compared to manual methods like stick welding.

High Productivity: MIG welding is well-suited for high-volume, repetitive tasks. Its efficiency and speed make it a preferred method in industrial and manufacturing settings where time and output are critical.

Clean Welds with Minimal Cleanup: Since MIG welding uses a shielding gas to protect the weld pool, it produces cleaner welds with minimal spatter or slag. This reduces the time and effort required for post-weld cleaning.

Highly Versatile: MIG welding works effectively with a variety of metals including carbon steel, stainless steel, and aluminum. This versatility makes it useful for many different applications.

Strong on Thicker Materials: It performs well on medium to thick materials, providing deep penetration and strong joints.

Automation-Friendly: MIG welding is compatible with automated and robotic systems, enhancing efficiency in mass production environments.

Limitations of MIG Welding

Requires Clean Surfaces for Quality Welds: MIG welding is sensitive to contaminants like rust, oil, dirt, and paint. To achieve strong, high-quality welds, the workpiece must be thoroughly cleaned beforehand. Failure to do so can result in poor penetration, porosity, and weak joints.

Less Portable Equipment: MIG welding systems typically require bulky equipment, including a constant power supply and gas cylinders for shielding. This setup makes it less portable than some other welding methods, such as stick welding, which is more compact and easier to transport.

Not Suitable for Outdoor Conditions: The shielding gas used in MIG welding can be easily disrupted by wind, which compromises weld quality. For this reason, MIG welding is not ideal for outdoor work unless wind barriers or specialized shielding methods are used.

Risk of Burn-Through on Thin Materials: The high heat and fast wire feed rate can cause burn-through when welding very thin metals. This limits its effectiveness for delicate sheet metal or precision applications.

Less Precision Than TIG Welding: MIG welding is generally less precise and less suited for intricate or artistic welds, where TIG welding excels.

Ongoing Consumable Costs: The continuous need for wire electrodes and shielding gas can result in higher long-term operating costs compared to some other welding methods.

Example of MIG Welding:

MIG welding is widely used in the automotive repair industry due to its speed, efficiency, and strong weld quality. For example, when a vehicle’s body panel or frame is damaged in a collision, technicians often use MIG welding to repair or replace the affected parts. The process involves feeding a continuous wire electrode through the welding gun, which melts and fuses the replacement metal to the existing structure. The shielding gas, commonly a mix of argon and carbon dioxide, protects the weld from contamination and oxidation, resulting in a clean, durable joint.

This method is particularly advantageous in auto body shops because it allows for quick repairs, reducing vehicle downtime and labor costs. The continuous wire feed eliminates frequent stops and starts, making it easier to create long, consistent welds. Additionally, MIG welding’s versatility means it can be used on various metals commonly found in vehicles, including steel and aluminum.

The ease of learning MIG welding also enables many repair technicians to perform high-quality welds without extensive training. Overall, MIG welding’s speed, reliability, and adaptability make it an ideal choice for automotive repair, ensuring strong and safe vehicle repairs while maintaining production efficiency.

TIG Welding (Tungsten Inert Gas Welding)

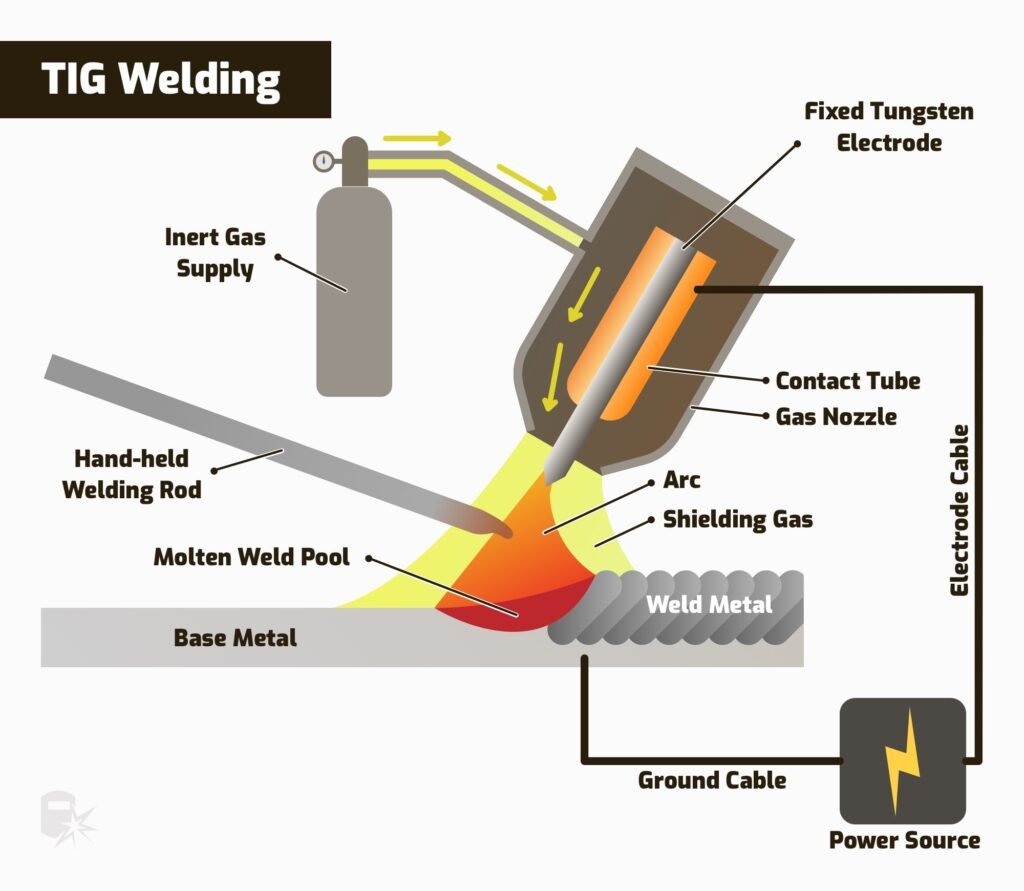

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a precision welding process that utilizes a non-consumable tungsten electrode to produce the weld. Unlike MIG welding, which uses a continuously fed wire, TIG welding typically involves manually adding a separate filler rod when needed. The welding area is shielded from atmospheric contamination by an inert gas, usually argon, which protects the molten metal and ensures a clean, high-quality weld.

One of the most notable features of TIG welding is its exceptional precision and control. The process allows welders to finely regulate heat input and manipulate the weld pool with accuracy, making it ideal for intricate and delicate work. This precision is especially valuable in applications where appearance and minimal distortion are important.

Another significant advantage of TIG welding is the cleanliness and quality of the welds it produces. Because the process does not involve spatter or slag, the resulting welds are smooth, aesthetically pleasing, and often require little to no post-weld cleanup. The controlled environment provided by the shielding gas also helps prevent oxidation and contamination, which contributes to the strength and durability of the weld.

TIG welding is commonly used in industries and applications where quality and precision are critical. For example, it plays a major role in aerospace manufacturing, where even the smallest defects in a weld can lead to serious performance issues. It is also widely used in pipe welding, custom metal artwork, and high-end fabrication, where visual appearance and exacting standards are paramount.

The process is particularly well-suited to thin materials and non-ferrous metals, such as aluminum, magnesium, copper, and their alloys. These metals are often sensitive to contamination and heat distortion, making TIG welding a preferred method due to its clean, controlled arc and focused heat. It can also be used on stainless steel and other challenging materials with great results.

Despite its many advantages, TIG welding is more difficult to master compared to other welding processes like MIG or stick welding. It typically requires the use of both hands—one to control the welding torch and the other to feed the filler rod—making coordination and skill essential. Additionally, the slower pace of TIG welding means it is less efficient for large-scale production, but it excels in applications where quality takes precedence over speed.

In conclusion, TIG welding is a versatile and highly precise welding technique that delivers top-tier results in demanding environments. While it requires a higher level of skill and patience to learn, the clean and strong welds it produces make it indispensable in fields where weld integrity and appearance matter most. From aerospace components to artistic metalwork, TIG welding remains a vital tool for professionals who demand excellence.

Advantages of TIG Welding

Produces High-Quality, Clean, and Attractive Welds: TIG (Tungsten Inert Gas) welding is renowned for creating precise and visually appealing welds. The process allows for smooth, clean finishes that require little to no post-weld grinding or finishing, making it ideal for visible or cosmetic applications.

Excellent Control Over Heat and Weld Pool: TIG welding provides the welder with fine control over the welding arc and heat input. This control is especially useful when working on complex joints or when precision is critical, enabling more accurate and consistent welds.

Ideal for Thin or Heat-Sensitive Materials: Thanks to its precise heat control, TIG welding is perfect for welding thin metals without causing burn-through or distortion. This makes it an excellent choice for detailed work or delicate components.

Compatible with a Wide Range of Metals: TIG welding can be used on a variety of ferrous and non-ferrous metals, including aluminum, stainless steel, copper, titanium, and magnesium. This versatility makes it useful across many industries.

No Spatter or Slag: Since TIG welding does not rely on filler wire or flux in all cases, it produces clean welds with virtually no spatter or slag, reducing cleanup time.

Preferred for High-Integrity Applications: TIG is often used in industries like aerospace, food processing, and custom fabrication, where both structural integrity and appearance are crucial.

Stable Arc with Non-Consumable Tungsten Electrode: The use of a non-consumable tungsten electrode results in a stable, consistent arc, enhancing weld quality and precision throughout the process.

Limitations of TIG Welding

Slower Welding Process: TIG welding is a relatively slow method compared to MIG or stick welding. Due to the precise nature of the process and the need for careful control, it is not ideal for high-volume or time-sensitive production work where speed is a priority.

Requires High Skill Level: TIG welding demands significant hand-eye coordination and practice. The welder must simultaneously control the torch, filler rod, and foot pedal (if used), making it one of the most technically demanding welding techniques to master.

More Expensive Equipment and Setup: TIG welding equipment tends to be more complex and costly than other methods. In addition to the welding machine itself, a high-quality tungsten electrode, shielding gas, and additional accessories are needed, increasing the initial investment.

Limited Portability: Like MIG welding, TIG welding requires a stable power supply and shielding gas, which limits its portability. It is less convenient for remote or mobile work sites.

Sensitive to Environmental Conditions: The shielding gas can be disrupted by wind, making TIG welding unsuitable for outdoor environments without proper protection.

Not Effective on Contaminated Metals: Dirty, oily, or rusty surfaces must be thoroughly cleaned before TIG welding, as contaminants can severely impact weld quality.

Longer Learning Curve: Compared to MIG or stick welding, TIG takes more time and training to learn properly, making it less accessible for beginners.

Example of TIG Welding:

TIG welding is widely used in the aerospace industry where precision, strength, and weld quality are paramount. For instance, when manufacturing aircraft components such as fuel tanks, engine parts, or structural frames, TIG welding allows welders to join thin sheets of aluminum or stainless steel with exceptional accuracy. The non-consumable tungsten electrode produces a stable arc that can be precisely controlled, minimizing heat input and reducing the risk of warping or distortion in delicate parts.

The shielding gas, typically pure argon, protects the weld area from contamination, ensuring clean, high-quality joints free of oxidation or impurities. Unlike other welding methods, TIG welding produces virtually no spatter or slag, which means little to no post-weld cleanup is required—a critical factor when working with complex or sensitive aerospace components.

TIG welding’s ability to handle exotic metals and alloys also makes it essential in custom fabrication, such as creating stainless steel piping for pharmaceutical equipment or artistic metal sculptures where visual appearance is important. Although TIG welding is slower and requires greater skill compared to MIG welding, its precision and superior weld quality make it the preferred choice for applications where safety and aesthetics cannot be compromised.

Conclusion

Both MIG and TIG welding are essential and widely used welding processes, each with its own strengths and ideal applications. MIG welding offers speed, ease of use, and versatility, making it perfect for large-scale production, thicker materials, and beginners. Its efficiency suits industries like automotive repair and construction where productivity is key. On the other hand, TIG welding provides unmatched precision, control, and clean welds, excelling in delicate or high-quality work on thin and specialized metals. While TIG requires more skill and is slower, it is the preferred choice for applications demanding superior weld integrity and appearance, such as aerospace and custom fabrication. Ultimately, the choice between MIG and TIG welding depends on the specific requirements of the project—balancing speed and ease versus precision and finish quality.