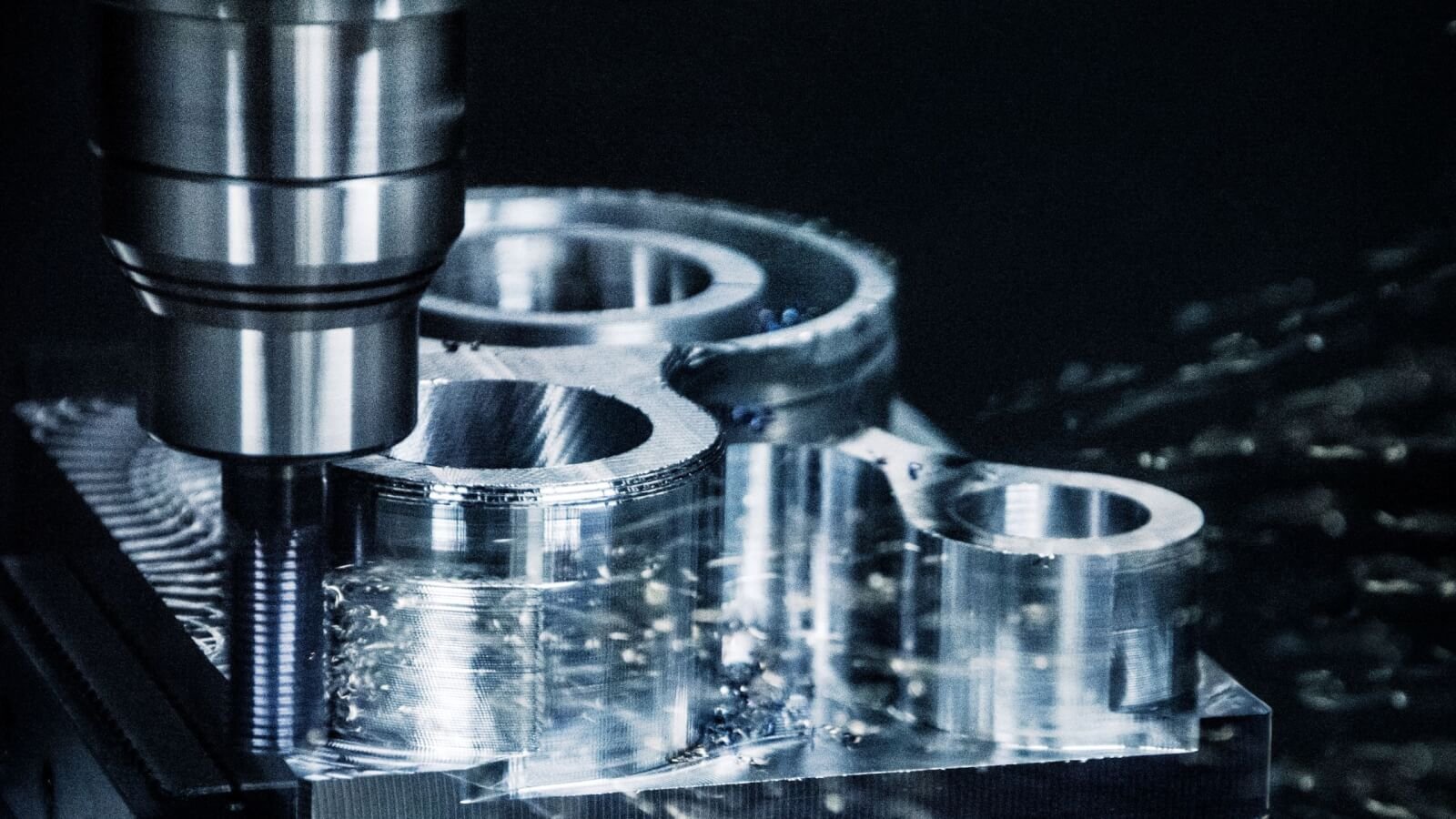

What is Machining?

Machining is a manufacturing technique that shapes a workpiece by cutting away excess material using various tools. As a subtractive process, it removes material rather than adding it. This method is commonly employed in industries such as aerospace, automotive, and medical device production due to its precision and versatility.

Types of Machining

- Turning

- Milling

- Drilling

- Grinding

- Boring

- Broaching

- Sawing

- Electrical Discharge Machining (EDM)

- Waterjet Cutting

- Laser Cutting

- Planing

- Shaping

- Honing

- Lapping

- Reaming

- Knurling

- Ultrasonic Machining (USM)

- Chemical Machining (CHM)

- Plasma Arc Machining (PAM)

- Electron Beam Machining (EBM)

- Ion Beam Machining (IBM)

- Cryogenic Machining

- Know more

Turning

Turning is a fundamental machining process in which a cutting tool removes material from the surface of a rotating workpiece to form cylindrical shapes. This subtractive process is typically carried out on a lathe, where the cutting tool moves in a straight path while the workpiece spins.

Types of Turning

Straight Turning

Removes material along the length of the workpiece to produce a uniform diameter.Taper Turning

Forms a conical shape by gradually reducing the diameter along the length.Profiling

Creates curved or complex external contours on the workpiece.Facing

Flattens the end of the workpiece by cutting across its face.Parting (Cut-off)

Separates a section of the workpiece by cutting completely through it.Grooving

Cuts narrow channels or recesses into the outer surface.Thread Cutting

Produces helical grooves (threads), commonly used for screws and bolts.Boring

Enlarges existing holes with high accuracy and surface finish.Drilling (on a lathe)

Uses a stationary drill bit to bore into the center of a rotating workpiece.

Applications of Turning

Turning is widely used across various industries to manufacture:

General Parts: Shafts, bushings, bolts, nuts, pistons

Automotive: Engine components, drive shafts, axles

Aerospace: Hydraulic rods, fasteners, precision connectors

Medical: Orthopedic implants, surgical instruments

Industrial: Tooling components, spindles, machine parts

Machines Used in Turning

Engine Lathe

Manually controlled, versatile for general machining tasks.Turret Lathe

Allows for quick tool changes and is suitable for batch production.CNC Lathe (Computer Numerical Control)

Automated and programmable, ideal for high precision and complex, repetitive tasks.Capstan Lathe

Similar to a turret lathe, used for medium-volume work.Bench Lathe

Small and compact, used for light-duty tasks and educational purposes.

Advantages of Turning

Advantages of Turning

High precision and dimensional consistency (especially with CNC)

Excellent surface finish quality

Adaptable to a variety of shapes and sizes

Compatible with many materials including metals, plastics, and composites

Straightforward setup and operation

Disadvantages of Turning

Disadvantages of Turning

Only suitable for parts with rotational symmetry

Generates material waste due to its subtractive nature

Manual operation requires skilled machinists

Inefficient for producing highly complex, non-cylindrical geometries

CNC setups involve higher initial and tooling cost

Milling

Milling is a machining process that involves a rotating cutting tool removing material from a stationary or moving workpiece. As a subtractive manufacturing method, it is used to produce flat surfaces, slots, holes, and complex 3D shapes. The operation is typically performed on a milling machine, which allows movement along multiple axes (X, Y, and Z) to achieve the desired geometry.

Types of Milling

Face Milling

Primarily cuts with the end of the cutter, ideal for creating flat surfaces.Peripheral (Slab) Milling

Cutting occurs along the sides of the tool, used for machining large, flat surfaces parallel to the tool’s axis.End Milling

Utilizes end mills for cutting slots, contours, and pockets—well-suited for complex 3D surfaces.Slot Milling

Involves cutting narrow grooves or channels using a slim cutter.Angular Milling

Performs cuts at specific angles to the horizontal plane, used for chamfers or angled surfaces.Form Milling

Employs specially shaped cutters to generate curved or irregular profiles.Gear Milling

Uses form tools to cut gear teeth profiles accurately.Straddle Milling

Two cutters operate simultaneously on opposite sides of a workpiece to machine two parallel surfaces.Gang Milling

Involves multiple cutters mounted on a single arbor to perform several cuts in one pass.

Applications of Milling

Milling is widely utilized in various industries for manufacturing components such as:

Mechanical Parts: Brackets, housings, engine blocks

Tooling Equipment: Molds, dies, jigs, fixtures

Automotive Components: Transmission parts, cylinder heads

Aerospace Structures: Wing elements, housings, precision fittings

Electronics: Heat sinks, device enclosures

Medical Devices: Prosthetics, surgical instruments, orthopedic implants

Machines Used in Milling

Vertical Milling Machine

Features a vertical spindle; commonly used for face and end milling tasks.Horizontal Milling Machine

Has a horizontal spindle, suited for slab and gang milling operations.Universal Milling Machine

Offers both vertical and horizontal spindle orientations for enhanced versatility.CNC Milling Machine

Fully automated and programmable, capable of high-precision and complex multi-axis machining.Manual Milling Machine

Manually operated, ideal for small-scale projects and prototyping.Bed-Type Milling Machine

Provides a fixed workpiece bed for improved stability, used for large or heavy parts.

✅ Advantages of Milling

Capable of producing complex geometries and detailed features

Supports a wide variety of materials, including metals, plastics, and composites

Offers high precision and repeatability, especially with CNC machines

Well-suited for flat surface machining, slots, and cavities

Multi-axis movement allows for intricate 3D contouring

❌ Disadvantages of Milling

Generates material waste due to its subtractive nature

Involves more complex setup than simpler operations like turning

Less efficient for purely cylindrical parts compared to turning

Requires skilled operators or programmers, particularly for CNC systems

High initial investment for CNC equipment and tooling

Drilling

Drilling is a machining process that uses a rotating drill bit to create round holes in a workpiece. As a subtractive method, it’s commonly used for preparing holes for fasteners, fluid flow, or further machining operations.

Types of Drilling

Standard Drilling – Produces straight, cylindrical holes.

Center Drilling – Accurately starts holes to guide deeper drilling.

Deep Hole Drilling – Used for holes with high depth-to-diameter ratios.

Reaming – Enlarges and finishes existing holes with high precision.

Counterboring – Creates a flat-bottom recess for bolt or screw heads.

Countersinking – Produces a conical hole entry for flat-head screws.

Spot Drilling – Marks exact locations to begin drilling.

Applications of Drilling

Drilling is essential in many fields, including:

Automotive: Engine components, mounting brackets

Construction: Beams, structural frameworks

Electronics: PCBs, casing holes

Manufacturing: Tooling, jigs, and fixtures

Medical: Surgical tools, implant preparation

Machines Used in Drilling

Drill Press (Bench/Floor) – Common for precise vertical drilling.

Radial Drilling Machine – Suited for large or heavy parts.

CNC Drilling Machine – Automated and accurate, ideal for mass production.

Handheld Drill – Versatile and portable for on-site tasks.

Lathe (Drilling on Lathe) – Drills axial holes in cylindrical workpieces.

✅ Advantages of Drilling

Fast and straightforward

Cost-effective and widely available

Compatible with various materials

High efficiency with CNC automation

❌ Disadvantages of Drilling

Limited to circular holes

Surface finish may be rough without further finishing

Tool wear can reduce precision

May leave burrs that need secondary operations

Grinding

Grinding machining is a process that removes small amounts of material using a special wheel made of tiny, hard particles (called abrasives). It’s mostly used to give parts a smooth finish and very accurate size, often after other cutting processes. It works on both metal and non-metal materials.

1. What is Grinding?

Grinding is a way to smooth and shape a surface by using a spinning abrasive wheel. This wheel slowly removes small bits from the surface of a part.

2. Types of Grinding

There are different methods of grinding based on the shape and type of part:

a. Surface Grinding

Flattens and smooths surfaces using a rotating wheel.

b. Cylindrical Grinding

Shapes the outside of round objects (like rods or shafts).

c. Centerless Grinding

Similar to cylindrical grinding, but the part isn’t held in place by centers. It rests on a support and is rotated by a second wheel.

d. Internal Grinding

Works on the inside of round holes or cylinders.

e. Creep Feed Grinding

Removes a lot of material slowly and deeply in one pass.

f. Form Grinding

The wheel is shaped to match the pattern or contour of the part being ground.

g. Gear Grinding

Specifically used to shape and finish gears.

3. Uses of Grinding

Grinding is used in many industries, especially where precision is important:

Making tools and molds

Auto parts like gears, bearings, and shafts

Aircraft components

Making sharp tools (e.g., drills, cutters)

Surgical tools and precision parts

Polishing molds and dies

4. Machines Used in Grinding

There are different machines for different grinding jobs:

Surface grinder

Cylindrical grinder

Centerless grinder

Internal grinder

Tool & cutter grinder

Bench grinder (usually small and used manually)

Belt grinder

Jig grinder

Gear grinder

5. Advantages of Grinding

Very smooth surface finish

Can reach high accuracy

Works on very hard materials

Can be automated in factories

Good for complex shapes

6. Disadvantages of Grinding

Slow compared to other cutting processes

Can get very hot, which might harm the part

Expensive machines and grinding wheels

Needs cooling liquid to control heat and dust

Not great for soft materials (they clog the wheel)

Boring

Boring is a process used in manufacturing to enlarge an existing hole in a part. It uses a cutting tool (called a boring bar) to make the hole bigger, smoother, and more accurate. It’s often used after drilling to improve the size and finish of the hole.

1. What is Boring?

Boring is a type of machining process where a single-point cutting tool is used to make a hole larger and more precise. It can improve the diameter, roundness, and surface finish of the hole.

2. Types of Boring

There are different types of boring, depending on how and where it’s done:

a. Horizontal Boring

The tool moves horizontally. Used for large or long parts.

b. Vertical Boring

The tool moves vertically. Often used for heavy and round parts.

c. Line Boring

Enlarges multiple holes in a straight line, often in large parts like engine blocks.

d. Back Boring

Enlarges a hole from the opposite side of the part, usually in tight spaces.

e. Jig Boring

Very high-precision boring done with special machines, often for holes that need tight tolerances.

3. Uses of Boring

Boring is used in many industries to improve hole quality:

Engines (e.g., cylinder bores)

Gearboxes

Aerospace parts

Large machine parts

Pipes and tubes

Tool and die making

4. Machines Used in Boring

Here are some common machines used for boring:

Boring mills (horizontal or vertical)

CNC boring machines (automated, very accurate)

Jig boring machines (for precise holes)

Lathes (can also be used for boring on round parts)

Machining centers (with boring heads)

5. Advantages of Boring

Improves hole size and finish

Can handle large and deep holes

Works on both soft and hard materials

Very accurate and consistent

Can be automated in CNC machines

6. Disadvantages of Boring

Slower than drilling for removing lots of material

Requires a pre-drilled hole

Machines can be large and expensive

Tool deflection can happen with long boring bars

Setup and alignment can be complex for precision work

Broaching

Broaching is a machining process used to remove material with a special tool called a broach. It’s used to create accurate shapes such as holes, keyways, splines, and flat surfaces in one pass. It is fast and very precise.

1. What is Broaching?

Broaching is a cutting process where a long tool with many cutting teeth (the broach) is pushed or pulled across a surface or through a hole. Each tooth removes a little more material, so the shape is made in just one pass.

2. Types of Broaching

Broaching can be divided into several types based on the direction and where it is used:

a. External Broaching (Surface Broaching)

Removes material from the outside of a part to make flat or contoured surfaces.

b. Internal Broaching

Used to enlarge or shape the inside of a hole (e.g., making keyways, hexagonal holes, or splines).

c. Push Broaching

The broach is pushed through the workpiece.

d. Pull Broaching

The broach is pulled through the workpiece (most common method).

e. Rotary Broaching

The broach rotates as it cuts, often used on lathes to make shapes like hex holes.

f. Continuous Broaching

Used in mass production. Parts move continuously while the broach cuts.

3. Uses of Broaching

Broaching is used when high precision and complex shapes are needed quickly:

Keyways in gears and pulleys

Splines and serrations in shafts

Hex or square holes

Rifle barrels (internal rifling)

Turbine disks

Aerospace and automotive components

4. Machines Used in Broaching

Broaching requires special machines called broaching machines:

Horizontal broaching machine (for long or large parts)

Vertical broaching machine (for internal broaching)

Continuous broaching machine (for mass production)

Rotary broaching attachment (used with lathes or milling machines)

5. Advantages of Broaching

Very fast and efficient for high production

Accurate and repeatable results

Can make complex shapes in one pass

Produces good surface finish

Great for internal profiles that are hard to machine otherwise

6. Disadvantages of Broaching

High initial cost of broaches (custom tools are expensive)

Not flexible – one broach is made for one shape

Limited to softer materials (very hard materials wear out the tool)

Not ideal for low-volume production

Broaching machines are specialized and costly

Sawing

Sawing is a basic machining process used to cut materials into smaller pieces using a blade with teeth. It’s most often used to cut metal bars, rods, pipes, or sheets before they go through other machining steps.

1. What is Sawing?

Sawing is a cutting process where a toothed blade moves across a material to slice through it. It’s known for being fast, simple, and great for straight cuts.

2. Types of Sawing

Different sawing methods are used depending on the material and shape needed:

a. Band Sawing

A continuous looped blade (like a toothed belt) cuts straight or curved shapes. Ideal for both metal and wood.b. Circular Sawing

A fast-spinning circular blade (disk-shaped) is used mostly for straight cuts.c. Hack Sawing

A straight blade moves back and forth. Often used in manual or light cutting jobs.d. Power Sawing / Reciprocating Sawing

The blade moves quickly in a back-and-forth motion using a motor, suitable for tougher or thicker materials.e. Abrasive Sawing (Cut-off Saw)

Instead of teeth, it uses an abrasive wheel to cut hard materials like metals and ceramics.

3. Common Uses of Sawing

Sawing is often the first step in manufacturing. It helps prepare materials for other operations:

Cutting metal rods, bars, and pipes

Preparing raw material stock

Cutting metal sheets or plates to size

Making rough cuts for construction, automotive, or aerospace parts

Cutting wood, plastic, and ceramics

4. Sawing Machines

Various machines are used depending on the job:

Band saw machine

Circular saw machine

Hack saw machine (manual or powered)

Cold saw (precise cutting for metals)

Abrasive cut-off saw

CNC sawing machine (automated, high-precision cutting)

5. Advantages of Sawing

Fast and easy to set up

Cuts many types of materials

Can handle large or long pieces

Uses simple tools and machines

Some saws (like band saws) create less material waste

6. Disadvantages of Sawing

Less accurate than other machining processes

Often leaves rough edges that need extra finishing

Not ideal for detailed or fine cuts

Blade wear can reduce cut quality

May produce noise and vibrations

Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is a non-traditional machining process that removes material from a workpiece by means of electrical discharges (sparks). It is especially useful for machining hard metals or those difficult to machine with traditional techniques.

Definition of EDM

EDM is a process in which an electrically conductive workpiece is shaped using rapid, recurring electric sparks between the workpiece and an electrode submerged in a dielectric fluid. The spark generates intense heat (up to 12,000°C), which melts and vaporizes small amounts of material.

Types of EDM

Sinker EDM (Ram EDM / Cavity Type EDM)

Uses a shaped electrode (usually graphite or copper) that is sunk into the workpiece.

Primarily used for complex cavity shapes in molds and dies.

Wire EDM (Wire Cut EDM)

Uses a continuously moving thin wire (usually brass) as an electrode.

Used to cut complex 2D and 3D shapes in hard materials.

Hole Drilling EDM (Small Hole EDM)

Specialized for drilling very small, deep holes (e.g., in turbine blades).

Uses a tubular electrode and flushing system to remove debris.

Machines Used in EDM

Sinker EDM Machines: Vertical machines with tank setups.

Wire EDM Machines: CNC controlled, with high-precision wire feeding mechanisms.

Hole Drilling EDM Machines: Designed with rotating tubular electrodes and high-pressure flushing systems.

Uses of EDM

Die and mold making (e.g., injection molds, forging dies).

Aerospace components (e.g., turbine blades, fuel injector holes).

Medical devices (e.g., surgical tools, implants).

Automotive (e.g., engine parts, transmission components).

Electronics (e.g., micro-components, connectors).

Advantages of EDM

Can machine hard materials: Works with hardened steels, carbides, etc.

Complex shapes: Ideal for intricate, fine, or internal contours.

No mechanical stress: No contact between tool and workpiece.

High precision and surface finish: Very accurate for fine features.

Disadvantages of EDM

Slow material removal rate: Not ideal for high-volume or large parts.

Only conductive materials: Cannot machine non-conductive materials (plastics, ceramics).

Tool wear: Electrode wear can affect dimensional accuracy.

High operating costs: Due to electrodes, dielectric fluid, and machine maintenance.

Waterjet Cutting

Waterjet cutting is a non-thermal, non-traditional machining process that uses a high-pressure stream of water—sometimes mixed with abrasive particles—to cut a wide range of materials. It is known for its precision, cold-cutting capabilities, and versatility.

Definition of Waterjet Cutting

Waterjet cutting is a material-cutting process where a jet of water (up to 60,000 psi or more) is used to erode the material along a programmed path. When cutting hard materials like metal or stone, abrasives such as garnet are added to the water stream to enhance cutting capability.

Types of Waterjet Cutting

Pure Waterjet Cutting

Uses only high-pressure water.

Suitable for soft materials like rubber, foam, textiles, paper, and food.

Abrasive Waterjet Cutting

Adds abrasive particles (like garnet) to the water stream.

Used to cut hard materials such as metal, stone, glass, and composites.

Machines Used in Waterjet Cutting

Waterjet Cutting Machine Components:

Pump: Pressurizes water (intensifier or direct-drive pump).

Cutting Head/Nozzle: Focuses the water stream and mixes abrasives (if used).

CNC Controller: Controls cutting path and speed.

Work Table: Where the material is placed for cutting.

Abrasive Delivery System (for abrasive jets).

Uses of Waterjet Cutting

Aerospace (e.g., cutting titanium and aluminum parts).

Automotive (e.g., interior components, body parts).

Construction (e.g., tiles, marble, granite cutting).

Food industry (e.g., precise cutting of frozen meat, pastries).

Metal fabrication (e.g., custom sheet metal parts).

Electronics (e.g., circuit boards, insulators).

Advantages of Waterjet Cutting

Cold cutting process: No heat-affected zones (HAZ); no thermal distortion.

Cuts virtually any material: Metal, plastic, glass, stone, rubber, composites.

High precision and edge quality: Minimal need for secondary finishing.

Environmentally friendly: No toxic fumes or chemical reactions.

No tool wear: No mechanical contact with the material.

Disadvantages of Waterjet Cutting

Slower than laser/plasma for thin metals.

High initial and operating costs: Pumps, abrasives, water filtration.

Large floor space needed for equipment and water management.

Abrasive disposal: Used garnet must be handled and disposed of properly.

Limited depth of cut: Efficiency decreases with very thick materials.

Laser Cutting

Laser cutting is a thermal-based, non-contact machining process that uses a focused, high-powered laser beam to cut, melt, or vaporize materials. It is widely used for high-precision cutting of metals, plastics, wood, and other materials.

Definition of Laser Cutting

Laser cutting involves directing a concentrated beam of light (laser) through optics to a small, precise spot on a material. The intense heat either melts, burns, or vaporizes the material, with assist gases (oxygen, nitrogen, or air) used to improve cutting quality and remove molten material.

Types of Laser Cutting

CO₂ Laser Cutting

Uses a carbon dioxide gas mixture.

Good for cutting non-metallic materials like wood, plastics, glass, fabrics, and some metals.

Moderate power levels and lower operating costs.

Fiber Laser Cutting

Uses a solid-state laser made with optical fiber.

Best for cutting metals (steel, aluminum, brass, copper).

Faster and more energy-efficient than CO₂ lasers for metals.

Nd:YAG / Nd:YVO (Crystal Lasers)

High energy output; used for very fine, high-precision cuts.

Suitable for both metal and non-metal, but with higher operating costs.

Machines Used in Laser Cutting

Laser Cutting Machine Components:

Laser Source: CO₂, fiber, or crystal.

Cutting Head: Focuses the beam with a lens.

CNC Controller: Directs the laser movement.

Assist Gas System: Uses oxygen, nitrogen, or compressed air to aid cutting.

Work Table: Fixed or movable platform where the material is placed.

Uses of Laser Cutting

Metal fabrication (e.g., sheet metal, brackets, enclosures).

Electronics (e.g., PCB cutting, battery components).

Automotive (e.g., body panels, interior parts).

Aerospace (e.g., precision components).

Signage and decoration (e.g., acrylic letters, wood art).

Medical (e.g., surgical tools, implant parts).

Advantages of Laser Cutting

High precision and accuracy: Suitable for intricate designs.

Clean cuts with smooth edges: Often no post-processing required.

Fast cutting speed: Especially for thin materials.

Minimal material waste: Narrow kerf width.

Automation-ready: Easily integrated into CNC and robotic systems.

Disadvantages of Laser Cutting

High equipment cost: Expensive machines and maintenance.

Heat-affected zone (HAZ): Possible thermal distortion on some materials.

Limited thickness: Not suitable for very thick materials.

Material restrictions: Some materials (e.g., reflective metals, PVC) are harder or hazardous to cut.

Requires ventilation: Fumes and gases may be toxic depending on the material.

Planing

Planing is a traditional machining process in which material is removed from a workpiece using a single-point cutting tool. In this process, the workpiece moves linearly while the cutting tool remains stationary (opposite of shaping, where the tool moves and the workpiece stays still). Planing is mainly used for producing flat surfaces.

Definition of Planing

Planing is a mechanical machining process where a large workpiece is mounted on a reciprocating table that moves it back and forth under a stationary cutting tool. The tool removes material during the forward stroke, while the return stroke is idle (non-cutting).

Types of Planing

Standard Planing (Horizontal Planer)

Horizontal movement of the workpiece under a fixed vertical cutting tool.

Used for flat and angular surfaces.

Pit Planing

The table is fixed, and the tool reciprocates (used in older or special large setups).

Commonly used in shipbuilding or very large workpieces.

Edge Planing (Edge Planer)

Designed for machining the edges of long plates or beams.

Typically used in structural steel fabrication.

Machines Used in Planing

Planer Machine Components:

Reciprocating Table: Moves the workpiece back and forth.

Tool Head: Holds the cutting tool, which can move vertically or across the table width.

Columns and Cross Rail: Support and guide the tool head movement.

Driving Mechanism: Provides the reciprocating motion.

Uses of Planing

Machining large flat surfaces (e.g., machine beds, tables).

Creating slots, grooves, and keyways in large components.

Planing structural components in shipbuilding and heavy equipment.

Repairing or resurfacing worn-out industrial equipment.

Advantages of Planing

Ideal for large workpieces: Can handle very heavy and large parts.

Simple setup: Good for producing flat and angular surfaces.

Uniform finish: Provides smooth and even surfaces.

Cost-effective for low-volume, heavy machining tasks.

Disadvantages of Planing

Low productivity: Material is removed only during the forward stroke.

High idle time: No cutting during return stroke.

Not suitable for small parts: More efficient processes exist for small-scale work.

Obsolete in many industries: Replaced by milling and CNC machining in most modern applications.

Manual tool setting: Less automated compared to modern machines.

Shaping

Shaping is a traditional machining process where a single-point cutting tool moves back and forth in a linear reciprocating motion to remove material from a stationary workpiece. It is mainly used to produce flat surfaces, grooves, and other simple geometries.

Definition of Shaping

Shaping is a machining process in which the tool moves, while the workpiece remains stationary (the opposite of planing). During the forward stroke, the cutting tool removes material, and during the return stroke, the tool lifts off slightly to avoid cutting.

Types of Shaping

Standard Shaping

The tool moves horizontally over the stationary workpiece.

Used mainly for flat surfaces, slots, and grooves.

Vertical Shaping

The tool moves vertically.

Useful for machining keyways or T-slots on shafts.

Angular Shaping

The tool or the workpiece is set at an angle to produce angular surfaces.

Machines Used in Shaping

Shaper Machine Components:

Ram/Slide: Holds the cutting tool and moves back and forth.

Work Table: Holds and clamps the workpiece; may swivel or move vertically.

Tool Head: Adjustable for height and angle.

Drive Mechanism: Powers the reciprocating motion of the ram.

Uses of Shaping

Machining flat surfaces on small to medium-sized workpieces.

Cutting slots, grooves, and keyways.

Producing irregular or curved surfaces by controlling tool movement.

Creating internal shapes inaccessible by other processes.

Advantages of Shaping

Simple and inexpensive machine.

Good for small to medium-sized workpieces.

Capable of machining flat and irregular surfaces.

Easy to operate and maintain.

Suitable for job-shop work and small batch production.

Disadvantages of Shaping

Low productivity: Cutting only occurs during the forward stroke.

Limited to relatively simple shapes.

Not suitable for large workpieces.

Manual setup: Less automation compared to modern CNC machines.

High idle time during the return stroke.

Honing

Honing is a process used to make the inside of holes (like in engine cylinders) super smooth, very accurate in size, and perfectly round. It’s like using a very fine sandpaper attached to a special tool to gently polish the inside of a hole.

What is Honing?

Honing is a way to finish the inside surface of holes using a tool with abrasive stones (gritty materials). These stones rub against the surface while spinning and moving back and forth. It removes tiny amounts of material to make the surface very smooth and precise.

Types of Honing

Manual Honing – Done by hand, mostly for small jobs or repairs.

Machine Honing – Done using a machine; faster and more accurate.

Single-Pass Honing – The tool goes through the hole only once.

Horizontal or Vertical Honing – Depends on how the machine is set up.

Machines Used in Honing

Honing Tool: Holds the abrasive stones.

Work Holder: Holds the part (like an engine block).

Motor: Makes the tool spin and move back and forth.

Where is Honing Used?

Cars – To smooth and size engine cylinders.

Aerospace – For parts that need very tight tolerances.

Factories – For making precise holes in tools and machines.

Repairs – To fix worn-out or scratched bores.

Advantages of Honing

Makes surfaces very smooth and shiny.

Makes holes very accurate in size and shape.

Helps parts last longer and run smoother.

Creates a pattern that holds oil, which reduces wear.

Doesn’t change the shape of the part from heat or force.

Disadvantages of Honing

Takes time – not good for removing a lot of material.

Needs special tools and machines.

The abrasive stones wear out and need replacement.

Mostly for inside holes – not used on outer surfaces.

Lapping

Lapping is a very gentle and precise finishing process used to make surfaces extremely flat, smooth, and shiny. It removes tiny bits of material using a soft tool and fine abrasive paste, similar to polishing—but much more accurate.

What is Lapping?

Lapping is done by rubbing the workpiece (the part you want to finish) against a flat surface called a lapping plate, with a gritty paste (abrasive slurry) in between. The tiny particles in the paste slowly wear away the surface, making it super smooth and flat.

Types of Lapping

Manual Lapping

Done by hand.

Used for small parts or high-precision polishing.

Machine Lapping

Uses a lapping machine with rotating plates.

Good for larger or multiple parts needing exact flatness.

Single-Sided Lapping

The workpiece is pressed against one lapping surface.

Double-Sided Lapping

The part is placed between two plates and both sides are lapped at once.

Machines Used in Lapping

Lapping Plate: A flat surface (usually made of cast iron or other soft metals).

Abrasive Slurry: A mix of oil or water and fine abrasive particles (like diamond or aluminum oxide).

Lapping Machine: Spins the plate and applies pressure to parts.

Where is Lapping Used?

Optics – To polish lenses and mirrors.

Mechanical parts – Like engine valves, seals, or metal plates.

Tool and die making – For extremely flat and smooth surfaces.

Measuring instruments – Where precision and flatness are critical.

Advantages of Lapping

Very smooth and shiny surface.

Makes surfaces extremely flat and accurate.

Great for parts that must fit together perfectly.

Works well on hard and soft materials.

Doesn’t heat or distort the material.

Disadvantages of Lapping

Very slow – removes only a tiny amount of material.

Not good for shaping – only for finishing.

Messy – the abrasive slurry can be hard to clean.

Needs skilled handling for best results.

High cost for precision applications.

Reaming

Reaming is a process used to make holes smooth, accurate, and the exact size. It is done after drilling to improve the finish and roundness of the hole using a special tool called a reamer.

What is Reaming?

Reaming is done by inserting a tool called a reamer into a hole that’s already been drilled. The reamer removes a small amount of material from the sides of the hole to make it perfectly round, smooth, and the correct size.

Types of Reaming

Hand Reaming

Done manually with a hand tool.

Used for small or precise jobs.

Machine Reaming

Done with a machine (like a drill press or lathe).

Faster and more consistent.

Fixed Reamer

Has a set size; can’t be adjusted.

Adjustable Reamer

Size can be slightly changed for flexibility.

Tapered Reamer

Used to enlarge holes with a taper (wider at one end).

Machines Used in Reaming

Drill Press

Lathe

Vertical Milling Machine

Hand Reaming Tool

Where is Reaming Used?

Automotive – For making accurate engine holes.

Aerospace – Where tight tolerances are critical.

Manufacturing – To finish holes for bolts, shafts, or pins.

Toolmaking – For fitting parts that must slide or press-fit.

Advantages of Reaming

Very accurate hole size.

Smooth surface finish inside the hole.

Fast and easy when done with a machine.

Less wear on tools than drilling large holes.

Great for improving drilled holes without reshaping them completely.

Disadvantages of Reaming

Can’t remove much material – the hole must be close to final size before reaming.

Only works on round holes – not for slots or irregular shapes.

Not suitable for very hard materials without special tools.

Reamers can be costly for custom sizes.

Needs precise alignment – otherwise, the hole may not be straight.

Knurling

Knurling is a process used to create a textured pattern (usually crisscrossed or straight lines) on the surface of a round metal part. This rough pattern makes the part easier to grip or can be used for decorative purposes.

What is Knurling?

Knurling is done by pressing a hard patterned tool (called a knurling tool) against a rotating workpiece (like a metal rod) on a lathe machine. It forms raised patterns on the surface by displacing the metal—not cutting it.

Types of Knurling Patterns

Straight Knurling

Parallel lines.

Used for grips that move in a straight line (like handles or knobs).

Diagonal Knurling

Slanted lines in one direction.

Mainly for decorative purposes.

Diamond Knurling

Crisscross pattern (most common).

Excellent grip, often seen on tool handles.

Machines Used in Knurling

Lathe Machine: The main machine used for knurling.

Knurling Tool: A tool with hardened rollers that press the pattern into the metal.

Where is Knurling Used?

Tool handles – For better grip.

Machine knobs – So they don’t slip in your hand.

Metal rods – To press-fit into plastic or other materials.

Decorative parts – For a patterned, professional look.

Fasteners and nuts – To provide grip or lock them in place.

Advantages of Knurling

Improves grip on metal surfaces.

Quick and easy to do on a lathe.

No material is removed – it’s just reshaped.

Looks decorative and professional.

Can be used to resize a slightly undersized part by increasing diameter.

Disadvantages of Knurling

Only works on round parts.

Requires a lathe and special tool.

Can damage soft metals if not done carefully.

Needs practice to get clean patterns.

Poor setup can cause tool chatter or pattern misalignment.

Ultrasonic Machining (USM)

Ultrasonic Machining (USM) is a special method of cutting hard and brittle materials (like glass, ceramics, or gemstones) using high-frequency sound vibrations. Instead of using sharp tools, it uses a vibrating tool and tiny particles to gently grind away the material.

What is Ultrasonic Machining?

In USM, a tool vibrates very fast (at ultrasonic frequency – around 20,000 to 40,000 times per second). It doesn’t cut the material directly. Instead, it transfers its vibrations to tiny abrasive particles in a slurry (a mix of water and abrasive powder), which then remove material from the workpiece by tiny impacts.

Types of Ultrasonic Machining

Conventional Ultrasonic Machining

Uses abrasives in a liquid slurry.

Most common form.

Rotary Ultrasonic Machining (RUM)

Tool vibrates and rotates at the same time.

Used for drilling or shaping holes in hard materials.

Machines Used in USM

Power Supply – Converts electrical energy into ultrasonic frequency.

Transducer – Converts electricity into vibrations.

Booster – Increases the amplitude of vibrations.

Horn/Tool Holder – Connects the vibrating system to the cutting tool.

Tool – Usually made of soft metals like brass or stainless steel (shaped like the hole you want).

Slurry Delivery System – Provides the abrasive liquid (usually with aluminum oxide or silicon carbide).

Where is Ultrasonic Machining Used?

Glass and ceramics – To make holes or cut shapes.

Jewelry – For precise and delicate cuts in gemstones.

Aerospace and medical – For hard, brittle, and delicate materials.

Electronics – For micro-machining silicon or other sensitive parts.

Precision dies and tools – For shaping small, detailed features.

Advantages of USM

Can cut very hard and brittle materials (like glass, quartz, and ceramics).

No heat produced – so no damage from heat.

Can make complex and delicate shapes.

No chemical reactions – safe for sensitive materials.

Great for materials that are difficult to machine by traditional methods.

Disadvantages of USM

Slow material removal rate – not good for big parts.

Tool wear – tools need frequent replacement.

Only works on brittle materials – not effective on soft metals.

High setup cost – machines are expensive.

Needs constant supply of abrasive slurry – can be messy and hard to manage.

Chemical Machining (CHM)

Knurling is a process used to create a textured pattern (usually crisscrossed or straight lines) on the surface of a round metal part. This rough pattern makes the part easier to grip or can be used for decorative purposes.

What is Chemical Machining?

In CHM, a metal part is coated with a protective layer (called a mask or resist). Then, the areas where you want to remove metal are uncovered, and the part is dipped into a chemical bath. The chemical etches away the exposed metal.

Types of Chemical Machining

Chemical Milling

Removes material from large areas.

Used to reduce thickness or shape big metal parts.

Chemical Blanking

Cuts or shapes thin sheets by removing material in specific patterns.

Similar to stamping but without force or heat.

Photochemical Machining (PCM)

Uses light to create very fine patterns on the metal.

Used for electronics, screens, and tiny metal parts.

Machines and Tools Used in CHM

Cleaning Equipment – To remove oils or dirt before processing.

Masking Materials – Waxes, paints, or photoresists to protect certain areas.

Chemical Tanks – Filled with acid or etchant.

Rinse and Drying Stations – To clean and finish the parts after etching.

Where is Chemical Machining Used?

Aerospace – To reduce weight by thinning out metal panels.

Electronics – For making circuit boards and metal screens.

Medical devices – For precise, small metal components.

Decorative items – Like nameplates, logos, or fine metal artwork.

Automotive – For detailed and lightweight metal parts.

Advantages of Chemical Machining

No cutting tools needed – no tool wear or vibration.

Can make very fine, detailed parts.

Works on very thin or delicate materials.

Good for making many parts at once.

No heat involved – no warping or hardening.

Disadvantages of Chemical Machining

Only works on certain materials (mostly metals that react with chemicals).

Chemicals can be dangerous – need special handling and disposal.

Not suitable for thick parts – only removes small amounts of material.

Slower than mechanical cutting for large jobs.

Accuracy depends on masking quality and chemical control.

Plasma Arc Machining (PAM)

Plasma Arc Machining (PAM) is a process that uses a high-velocity jet of hot plasma (ionized gas) to cut, melt, or remove material from a workpiece, usually metal. The plasma can reach temperatures of 20,000°C or more, which is hotter than the surface of the sun!

How Does It Work?

A gas (like nitrogen, argon, or hydrogen) is forced through a small nozzle.

An electric arc is created between an electrode and the metal surface.

This arc ionizes the gas and turns it into plasma.

The hot plasma melts the metal, and the force of the jet blows it away.

Types of Plasma Arc Machining

Transferred Arc PAM:

Arc is between the electrode and the workpiece.

More heat is transferred.

Mostly used for cutting.

Non-Transferred Arc PAM:

Arc is between the electrode and the nozzle.

Plasma jet hits the workpiece indirectly.

Used for applications like spraying or surface treatment.

Machines Used

Plasma cutting machines

CNC plasma machines (computer-controlled)

Handheld plasma torches

Robotic plasma systems (for automation)

Machines usually include a power supply, gas supply, plasma torch, and cooling system.

Applications

Cutting stainless steel, aluminum, copper, and titanium

Shipbuilding, automobile, aerospace, and construction

Cutting thick and hard metals

Making precise shapes or holes

Surface treatment or cleaning

Advantages

Very fast cutting speeds

Can cut thick and hard materials

High precision and clean edges

Works on electrically conductive materials

Less heat distortion compared to other thermal methods

Disadvantages

Only works on conductive materials

Produces noise, smoke, and UV radiation (needs safety precautions)

Expensive equipment

Requires skilled operators

Not suitable for fine, delicate work

Electron Beam Machining (EBM)

Electron Beam Machining (EBM) is a type of non-traditional machining where a beam of high-speed electrons is focused on a material to melt and vaporize it. This process is done in a vacuum chamber, and it’s mainly used for very precise and small-scale machining, especially on metals.

How Does It Work?

Electrons are generated by heating a filament (cathode).

These electrons are accelerated using a high voltage (up to 200,000 volts).

A magnetic lens focuses the beam onto a small spot on the workpiece.

The beam hits the surface with high energy and melts or vaporizes the material.

All this happens in a vacuum, so the electrons don’t scatter.

Types of EBM (Based on Application)

Continuous Beam:

Used for deep penetration, like drilling.

Beam is on constantly.

Pulsed Beam:

Used for precise cutting or micro-machining.

Beam is turned on and off in pulses.

Machines Used

Electron beam machine with:

Electron gun (filament + high-voltage source)

Magnetic focusing system

Worktable inside a vacuum chamber

Computer control (for CNC EBM systems)

Applications

Micro-drilling of very small holes (jet engine parts, fuel nozzles)

Welding and cutting very thin or delicate metals

Machining hard or brittle materials

Used in aerospace, electronics, medical devices, and nuclear industries

Creating fine patterns or shapes

Advantages

Can machine very small, precise holes

Works on hard and tough materials

No physical contact – no tool wear

Minimal heat-affected zone

Highly focused energy – excellent for micro-work

Disadvantages

Requires a high vacuum, making it expensive

Only works on conductive materials

Slow process for large parts

Not suitable for thick materials

Needs highly skilled operators

Ion Beam Machining (IBM)

Ion Beam Machining (IBM) is a non-traditional machining process where a beam of high-energy ions (charged particles) is used to remove material from a surface. It’s extremely precise and is mostly used for micromachining or surface modification in electronics and optics.

How Does It Work?

A gas (like argon) is ionized (turned into charged particles).

These ions are accelerated using a high voltage.

The ion beam is focused and directed at the surface.

When the ions hit the surface, they knock atoms out – this process is called sputtering.

It all happens in a vacuum chamber.

Types of Ion Beam Machining

Ion Beam Milling (Sputtering):

Material is slowly removed by physical bombardment.

Used for etching or shaping very small features.

Reactive Ion Etching (RIE) (in some setups):

Ions react chemically with the material.

Gives faster and more selective material removal.

Machines Used

Ion source/generator

Accelerator (for ion speed)

Focusing system (electrostatic or magnetic)

Vacuum chamber

CNC or computer control system

Applications

Making microchips and semiconductor devices

Patterning in microelectronics and nanotechnology

Etching optical lenses and mirrors

Precision shaping of MEMS devices (Micro-Electro-Mechanical Systems)

Thin film shaping or removal

Advantages

Extremely precise – can remove atoms layer by layer

No physical contact – no tool wear

Works on hard, brittle, or heat-sensitive materials

Can create complex nano-scale features

Very clean and controlled process

Disadvantages

Very slow material removal rate

Needs high vacuum – costly setup

Expensive to operate and maintain

Not suitable for large parts

Requires skilled technicians

Cryogenic Machining

Cryogenic Machining is a machining process where extremely cold fluids (like liquid nitrogen or carbon dioxide) are used to cool the cutting tool or workpiece during machining. This helps to reduce heat, improve tool life, and enhance surface finish, especially when cutting hard or tough materials.

Instead of traditional coolants (like oil or water), cryogenic fluids cool things down to very low temperatures (as low as -196°C).

How Does It Work?

A cryogenic fluid (usually liquid nitrogen (LN2) or liquid carbon dioxide (CO₂)) is stored in a tank.

The fluid is directed to the cutting zone through special nozzles.

It rapidly cools the cutting tool, the chip, or the workpiece.

This reduces heat, friction, and tool wear.

Types of Cryogenic Machining

External Cryogenic Cooling:

Coolant is sprayed on the tool or workpiece from outside.

Internal Cryogenic Cooling:

Coolant is passed through internal channels in the tool.

More efficient and targeted cooling.

Cryogenic Pre-Cooling:

The workpiece is cooled before machining begins.

Used for difficult materials like titanium.

Machines Used

Standard CNC machines with:

Cryogenic fluid storage tank

Pressure regulator and flow control

Insulated delivery lines and nozzles

Modified tool holders for internal cooling (if needed)

Applications

Aerospace (e.g., machining titanium, Inconel)

Medical implants (for smooth, clean cuts)

Automotive parts

Hard-to-machine metals like stainless steel and nickel alloys

Precision machining requiring excellent surface finish

Advantages

Reduces tool wear – tools last longer

Better surface finish

Handles difficult-to-machine materials

Eco-friendly – no toxic oils or fluids

Reduces thermal damage to the workpiece

Less need for post-processing

Disadvantages

High initial cost (equipment and cryogenic fluid)

Needs special equipment and safety precautions

Not suitable for all types of materials

Requires training for operators

Cryogenic fluids evaporate – not reusable

If there are any additional types of Machining that we may have missed, we welcome your input. Please feel free to leave a comment to help us improve and expand our understanding. Your feedback is valuable and appreciated..

Related posts:

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses

- 10 Must Have Machine Shop Tools Every Highly Efficient Workshop Needs

- Cutting Fluids in Machining – Types and Their 5 Critical Roles in Boosting Machining Quality

- 10 Best Materials Used in Machining: A Complete Guide for Manufacturers

- 8 Common Mistakes in Machining and How to Avoid Them