The machining industry is rapidly evolving due to automation, digitization, and sustainability. Automation enhances efficiency by using advanced robotics and CNC machines, reducing human error and boosting productivity. Digitization integrates IoT and data analytics, enabling real-time monitoring and predictive maintenance, which cuts downtime and improves quality. Sustainability is driving eco-friendly practices like energy-efficient equipment and waste reduction, aligning with global environmental goals. These trends collectively increase competitiveness and innovation within the sector. As machining adapts to these changes, companies embracing technology and green initiatives are better positioned to meet future demands and maintain industry leadership.

1. Automation & Smart Machining

The machining industry is experiencing a transformative phase fueled by advances in automation, robotics, and intelligent maintenance systems. These trends are reshaping traditional manufacturing processes to enhance productivity, precision, and sustainability.

a. CNC Automation

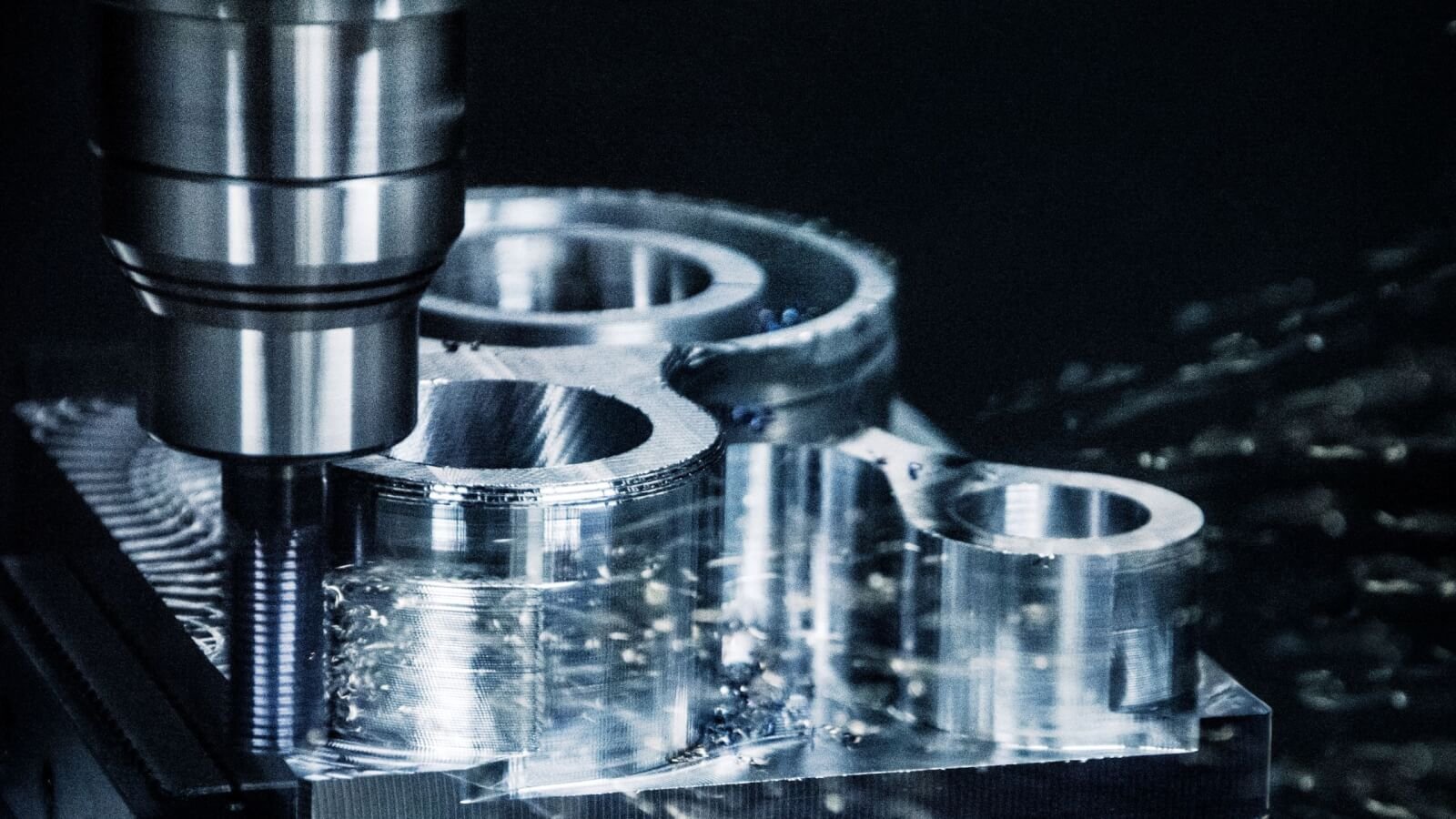

One of the most impactful trends in machining is the rise of automated CNC (Computer Numerical Control) machines. Modern CNC systems are increasingly integrated with robotic arms and automatic tool changers, creating highly efficient production lines. Automated CNC machining reduces the need for manual labor and minimizes human error, resulting in higher throughput and consistent quality.

A prime example of this advancement is lights-out manufacturing, where facilities operate autonomously 24/7 with minimal human supervision. In such environments, CNC machines, combined with robots, manage loading, machining, tool changes, and unloading seamlessly. This setup not only maximizes machine utilization but also significantly lowers labor costs. By running continuously, manufacturers can meet growing demands with faster turnaround times, making CNC automation a cornerstone of modern machining efficiency.

b. Robotic Integration

Robotic integration complements CNC automation by handling various peripheral tasks that traditionally required human intervention. Collaborative robots, or cobots, are gaining popularity because of their ability to safely work alongside humans. Cobots are often employed for loading and unloading parts, performing inspections, and assisting in assembly operations.

Unlike traditional industrial robots, cobots are flexible, easy to program, and ideal for small-batch or customized production runs. They improve worker safety by taking over repetitive or hazardous tasks, while freeing skilled operators to focus on more complex activities.

Additionally, custom automation cells are being designed around machining centers. These cells combine CNC machines, cobots, conveyors, and sensors into a streamlined production ecosystem. The integration enables seamless communication between machines and robotics, optimizing workflow, reducing cycle times, and boosting overall productivity.

c. Predictive Maintenance

Another critical advancement transforming machining is predictive maintenance, driven by the Internet of Things (IoT) and artificial intelligence (AI). IoT sensors installed on machines continuously monitor vital parameters such as temperature, vibration, and tool wear in real time. AI algorithms analyze this data to detect patterns indicating potential machine failures before they occur.

Predictive maintenance allows manufacturers to schedule maintenance activities precisely when needed, avoiding unexpected breakdowns and costly downtime. This shift from reactive to proactive maintenance enhances machine reliability and extends equipment lifespan.

Moreover, predictive maintenance contributes to cost savings by reducing unnecessary routine maintenance and preventing damage that could require expensive repairs. Real-time health monitoring also supports quality control by ensuring machines operate within optimal parameters, minimizing defective parts.

2. Industry 4.0 & Digital Transformation

The machining industry is increasingly leveraging digital technologies to enhance efficiency, precision, and flexibility. Key innovations such as digital twin technology, cloud-based platforms, and data-driven machining are revolutionizing how manufacturing processes are designed, monitored, and optimized.

a. Digital Twin Technology

Digital twin technology is transforming machining by creating virtual replicas of physical machining systems. These digital twins enable manufacturers to simulate and analyze machining processes in a virtual environment before applying changes on the shop floor. By replicating machine behavior, tooling, and process conditions, operators can optimize parameters, predict outcomes, and troubleshoot potential issues without halting production.

Real-time data from sensors continuously updates the digital twin, allowing for dynamic process control and adjustments. This capability improves precision and reduces errors, leading to higher-quality parts and lower scrap rates. Furthermore, digital twins facilitate scenario testing, enabling manufacturers to explore different machining strategies and materials virtually, thus accelerating innovation and reducing costly trial-and-error on actual machines.

b. Cloud-Based Platforms

Cloud-based platforms have become vital for modern machining operations by enabling remote monitoring, data analysis, and centralized management of machine fleets across multiple locations. Through cloud connectivity, manufacturers gain real-time visibility into machine status, performance metrics, and maintenance needs regardless of geographical barriers.

These platforms support predictive analytics by aggregating data from diverse sources, helping companies make informed decisions about production scheduling, resource allocation, and maintenance planning. Cloud solutions also improve collaboration by allowing engineers, operators, and managers to access shared dashboards and reports on any device.

The scalability of cloud infrastructure means manufacturers can easily expand operations and integrate new machines without heavy IT investments. Security features built into cloud platforms ensure that sensitive operational data is protected while enabling seamless software updates and integrations with other enterprise systems.

c. Data-Driven Machining

Data-driven machining leverages artificial intelligence (AI) and machine learning (ML) to enhance manufacturing precision and efficiency. By analyzing historical and real-time data, AI algorithms can predict tool wear, optimize cutting parameters, and implement adaptive control strategies tailored to specific machining tasks.

Predicting tool wear accurately helps in scheduling timely tool changes before failure occurs, preventing defects and unplanned downtime. AI-powered optimization adjusts cutting speeds, feed rates, and other parameters on the fly to maximize material removal rates while maintaining part quality and extending tool life.

Adaptive control systems use feedback from sensors to modify machining conditions dynamically, compensating for variations in material properties or machine vibrations. This intelligent approach improves consistency, reduces cycle times, and minimizes operator intervention.

Together, these AI and ML applications enable smarter, more autonomous machining processes that respond intelligently to changing conditions, pushing the boundaries of manufacturing performance.

3. Sustainability & Green Machining

The machining industry is increasingly prioritizing sustainability through innovations that reduce energy consumption, waste, and environmental impact. Key advancements such as energy-efficient machines, coolant recycling systems, and near-net shaping technologies are driving a greener manufacturing future.

a. Energy-Efficient Machines

Original Equipment Manufacturers (OEMs) are focusing on designing energy-efficient machining equipment to minimize power consumption without compromising performance. These machines incorporate advanced motor technologies, optimized drive systems, and improved thermal management to reduce energy waste.

Better thermal control systems help maintain consistent operating temperatures, which enhances machine accuracy and reduces wear on components. By lowering electricity use, energy-efficient machines contribute to significant cost savings over time and support manufacturers’ goals to reduce their carbon footprint.

This trend aligns with global initiatives encouraging sustainable industrial practices, making energy-efficient machining a critical component for companies aiming to meet environmental regulations and corporate social responsibility targets.

b. Coolant Recycling Systems

Coolant fluids are essential in machining for cooling and lubrication, but traditional systems generate large amounts of waste and pose environmental hazards. To address this, closed-loop coolant recycling systems have been developed, enabling the filtration, purification, and reuse of cutting fluids.

These systems capture and separate metal chips from coolant, filter out contaminants, and replenish fluid quality, drastically reducing the volume of waste coolant disposed of. The recycling process not only lowers operational costs by reducing coolant purchase and disposal expenses but also improves workplace safety by minimizing exposure to harmful chemicals.

By managing chip and coolant waste more effectively, manufacturers reduce environmental pollution and comply more easily with increasingly strict waste management regulations.

c. Near-Net Shaping

Near-net shaping technologies aim to minimize material waste by producing parts that are very close to final dimensions, reducing the amount of machining and material removal needed. Additive manufacturing, or 3D printing, is a prime example, often integrated with traditional subtractive machining in hybrid machines.

Hybrid machines combine additive processes like metal deposition with precision machining in a single setup. This approach allows manufacturers to build complex geometries layer by layer and then finish parts with high accuracy, optimizing material use.

Near-net shaping reduces raw material consumption, energy use associated with excessive cutting, and scrap generation. This not only lowers production costs but also supports circular economy principles by conserving valuable resources.

4. Workforce Evolution

The machining industry is undergoing a profound workforce transformation driven by automation, digitization, and advanced technologies. As machines become more intelligent and connected, the roles of human workers are evolving. Key trends shaping this shift include changes in skill demands, the adoption of immersive training technologies like AR/VR, and greater human-machine collaboration on the shop floor.

a. Skills Shift

The traditional role of the manual machinist is gradually being replaced or redefined as advanced technologies take over routine and repetitive tasks. Today, the industry increasingly seeks professionals with expertise in automation, robotics, data analytics, and digital systems integration.

Technologists, robotics engineers, and data analysts are in high demand to design, manage, and optimize complex machining systems. These roles require a strong understanding of both mechanical systems and digital tools such as CAD/CAM software, IoT platforms, and AI-driven analytics.

As a result, machining careers are shifting toward interdisciplinary skill sets, blending engineering, software, and operations knowledge. Manufacturers are investing more in workforce upskilling and collaborating with technical institutes to build talent pipelines for the next-generation workforce.

b. Training with AR/VR

Training and upskilling workers for these evolving roles have become more effective with the adoption of augmented reality (AR) and virtual reality (VR) technologies. VR enables immersive, interactive simulations of real-world machining environments, allowing operators to practice machine setup, tool changes, and maintenance procedures in a safe and controlled virtual space.

Trainees can engage with 3D models of machines, experience realistic failure scenarios, and learn step-by-step processes without risking damage to expensive equipment or personal injury. This speeds up the learning curve and increases confidence before entering live production environments.

AR, on the other hand, overlays digital instructions and real-time data onto physical machines using tablets or smart glasses, guiding workers through complex tasks with visual aids. This technology supports just-in-time learning and remote assistance, particularly valuable for troubleshooting and maintaining equipment in real-time.

c. Human-Machine Collaboration

As automation and intelligent systems become more prevalent, the role of the human operator is evolving from hands-on machining to supervisory and optimization functions. Rather than manually operating machines, workers now monitor systems, analyze performance data, and make adjustments to improve efficiency and quality.

This collaborative model enhances productivity while leveraging the strengths of both machines and humans. Machines handle repetitive, high-precision tasks, while human operators provide critical thinking, problem-solving, and decision-making skills. The result is a smarter and more agile production environment.

Human-machine collaboration also improves safety, as workers are distanced from hazardous operations, and enables more flexible production setups that adapt quickly to changes in demand or design.

5. Advanced Machining Techniques

The machining industry is embracing advanced technologies to meet the demands of high-performance, high-precision manufacturing. Key developments such as hybrid machining, micromachining, and multi-axis/multi-tasking machines are enabling manufacturers to produce complex components with greater speed, flexibility, and accuracy. These innovations are crucial for industries like aerospace, electronics, and medical devices, where performance and precision are non-negotiable.

a. Hybrid Machining

Hybrid machining combines additive and subtractive processes in a single machine, offering the benefits of both technologies. A common example is the integration of laser cladding (additive) with CNC milling (subtractive) in one system. This allows manufacturers to build up material where needed—such as for repairs or near-net shapes—and then finish the part to tight tolerances using traditional machining.

The ability to add material precisely and then machine it to final dimensions streamlines production and enables complex geometries that would be difficult or impossible to create using subtractive methods alone. Hybrid machines are particularly useful for high-value components in aerospace, tooling, and energy sectors, where part customization, repair, and design flexibility are critical.

Additionally, by reducing the number of separate manufacturing steps and setups, hybrid machining enhances efficiency and shortens lead times, offering significant competitive advantages.

b. Micromachining & Precision Manufacturing

Micromachining is gaining momentum as industries demand smaller, more intricate components with exacting tolerances. Sectors such as medical devices, electronics, and aerospace require micro-scale features and ultra-precise surface finishes that traditional machining cannot deliver.

Micromachining employs specialized tools and machines capable of handling parts measured in microns. It enables the production of microfluidic channels, stents, optical components, and miniature sensors with extreme accuracy. Advances in machine stability, vibration control, and spindle technology have made it possible to machine delicate materials like titanium, ceramics, and high-performance polymers at micro scales.

Precision manufacturing also involves tight process control, temperature regulation, and high-resolution measurement systems to maintain repeatability. This level of accuracy is critical for safety-critical applications like medical implants and aerospace components, where even the smallest deviation can lead to failure.

c. Multi-Axis & Multi-Tasking Machines

Multi-axis (such as 5-axis) and multi-tasking machines are revolutionizing how complex parts are produced. These machines can perform multiple operations—milling, turning, drilling, tapping—in a single setup and often on multiple axes simultaneously. This reduces the need for part transfers between machines, minimizes handling errors, and significantly shortens production cycles.

5-axis machining, in particular, allows for the creation of complex geometries with fewer tool changes and improved surface finishes. It is especially beneficial in industries where intricate contours and tight tolerances are essential.

Multi-tasking machines further streamline operations by combining multiple capabilities in one machine, improving efficiency, space utilization, and consistency across batches. They enable manufacturers to produce high-precision, complex parts faster and more reliably, while also reducing labor and operational costs.

Conclusion

The machining industry is undergoing a transformative shift driven by automation, digitization, and sustainability. At the core of this evolution lies the concept of Smart Machining—a comprehensive, future-focused approach that blends advanced technologies, data intelligence, and automation to create highly efficient, precise, and adaptive manufacturing environments.

CNC automation, robotic integration, and lights-out manufacturing are redefining productivity by minimizing manual intervention and maximizing machine utilization. These systems not only increase throughput but also improve accuracy, consistency, and scalability in complex part production. Complementing automation are digital innovations such as digital twin technology, predictive maintenance, and cloud-based platforms, which empower manufacturers to monitor operations in real time, simulate performance, and make data-driven decisions across multiple facilities and production lines.

Sustainability is equally central to the industry’s direction. Energy-efficient machinery, closed-loop coolant recycling systems, and near-net shaping methods are significantly reducing material waste, environmental impact, and operational costs—supporting both ecological goals and business efficiency. These sustainable approaches are also aligned with global regulations and corporate environmental responsibility commitments.

In parallel, the role of the workforce is evolving. The demand for traditional manual skills is giving way to positions requiring expertise in robotics, automation systems, data analysis, and process engineering. Advanced training tools like augmented reality (AR) and virtual reality (VR) are accelerating workforce development by providing immersive, hands-on learning environments without risk. Human-machine collaboration is also gaining importance, positioning workers as supervisors, analysts, and strategic decision-makers in increasingly autonomous and intelligent manufacturing systems.

Manufacturers that invest in Smart Machining are not just modernizing their processes—they are building resilience, innovation capacity, and long-term competitiveness. By embracing intelligent automation, digital connectivity, and sustainable practices, they can remain agile, future-ready, and equipped to meet the rising demands of global markets that prioritize quality, speed, customization, and environmental responsibility.

Related posts:

- Machining and Types of Machining.

- 5-Axis Machining vs 3-Axis Machining – Essential Differences, Applications & Limitations

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses

- 10 Must Have Machine Shop Tools Every Highly Efficient Workshop Needs

- 3D Printing vs Machining: Powerful Comparison of Benefits, Limitations, and Applications