Introduction

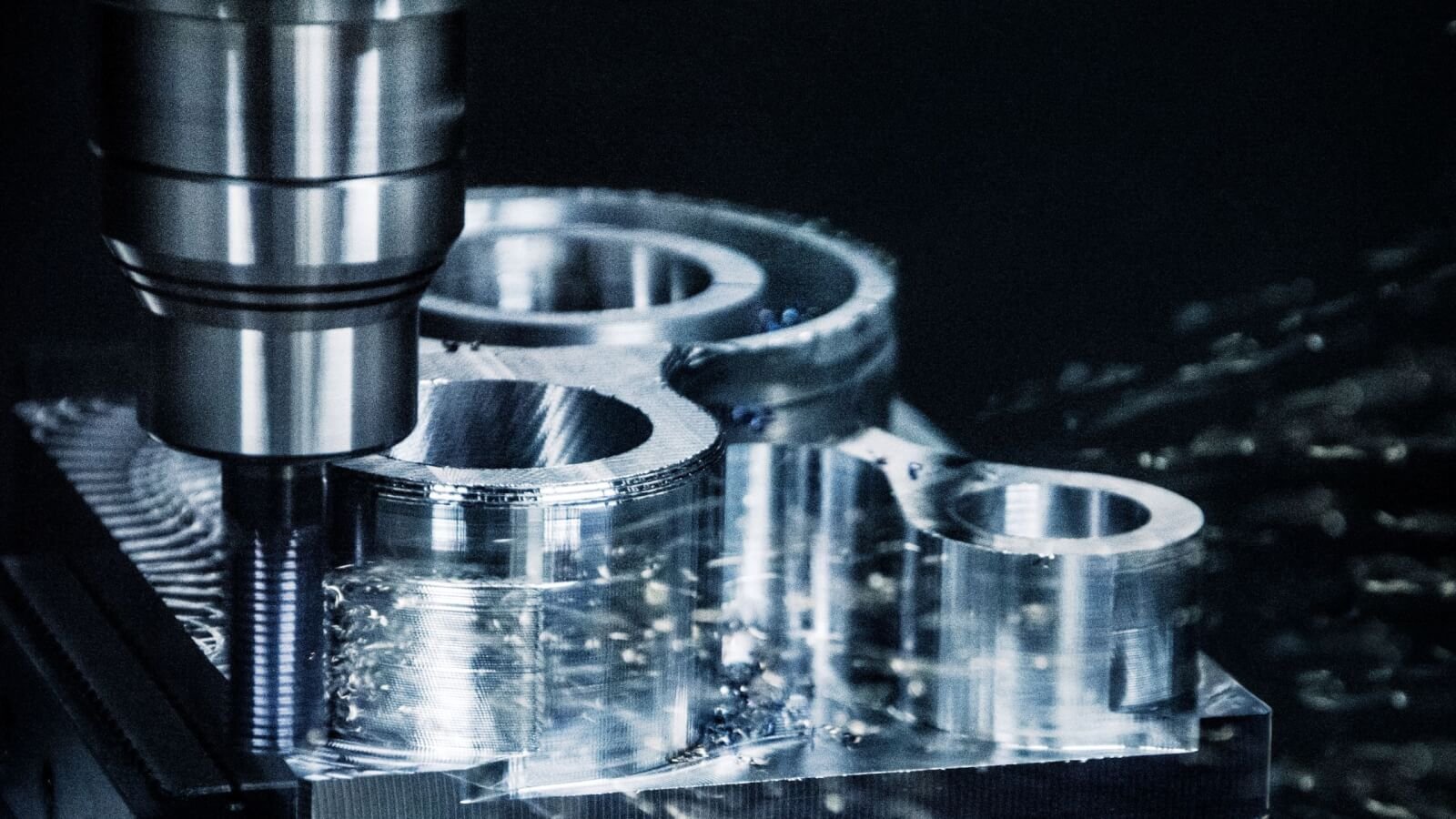

Machining is a fundamental manufacturing process that involves removing material from a workpiece to shape it into a desired geometry using various cutting tools. It plays a crucial role in modern industry, from precision medical devices to automotive components and aerospace parts. One of the most critical factors affecting the success, efficiency, and quality of machining operations is the choice of materials—both the material being machined (workpiece material) and the material of the cutting tool. Understanding the properties, challenges, and appropriate applications of these materials is essential for optimizing performance, reducing costs, and improving product quality.

This essay provides a detailed overview of materials used in machining. It discusses different types of workpiece materials and their machinability, the materials used for cutting tools, and the factors that influence material selection. The goal is to give a holistic understanding of how materials impact the machining process and what considerations must be taken into account to ensure successful outcomes.

1. Workpiece Materials

Workpiece materials refer to the materials being machined or shaped in the process. They exhibit a wide range of mechanical, thermal, and chemical properties that directly impact machinability—the ease with which a material can be machined.

1.1 Ferrous Metals

1.1.1 Carbon and Alloy Steels

Carbon steels and alloy steels are among the most commonly machined materials in manufacturing. They contain varying amounts of carbon and alloying elements like chromium, molybdenum, and nickel to improve properties such as strength and toughness.

Low-carbon steels are relatively easy to machine but may produce poor surface finishes.

Medium- and high-carbon steels are stronger but harder to machine due to increased hardness and reduced ductility.

Alloy steels offer improved mechanical properties and corrosion resistance but require special cutting tools and coolants to avoid excessive tool wear.

1.1.2 Stainless Steels

Stainless steels are corrosion-resistant alloys containing chromium, nickel, and sometimes molybdenum. Common grades include 304 and 316.

Machinability challenges: High toughness, work-hardening behavior, and low thermal conductivity.

Applications: Medical devices, food processing equipment, and marine parts.

1.1.3 Cast Iron

Cast iron is known for its good machinability due to its brittleness and graphite content, which acts as a lubricant during cutting.

Types: Gray iron (easy to machine), ductile iron (more difficult).

Applications: Engine blocks, machine bases, pipes.

1.2 Non-Ferrous Metals

1.2.1 Aluminum and Its Alloys

Aluminum is lightweight, corrosion-resistant, and easy to machine. It is highly popular in industries like aerospace, automotive, and electronics.

Advantages: High thermal conductivity, excellent surface finish, low tool wear.

Challenges: Tendency to stick to cutting tools (galling), especially in high-speed operations.

1.2.2 Copper and Brass

Copper is highly conductive and used in electrical applications, while brass (a copper-zinc alloy) is more machinable and used for fittings and valves.

Copper: Soft and ductile, but can cause built-up edge formation on cutting tools.

Brass: Excellent machinability, produces small chips and a good finish.

1.2.3 Titanium and Its Alloys

Titanium is known for its high strength-to-weight ratio and corrosion resistance. It is widely used in aerospace, medical, and military applications.

Challenges: Low thermal conductivity leads to localized heat, accelerating tool wear. It also has a tendency to work-harden.

1.3 Non-Metallic Materials

1.3.1 Plastics

Plastics such as Nylon, PTFE (Teflon), and acrylic are increasingly used in engineering applications.

Advantages: Lightweight, corrosion-resistant, low machining forces.

Challenges: Tendency to melt or deform under heat; requires sharp tools and proper speed/feed rates.

1.3.2 Composites

Composites like carbon fiber reinforced polymer (CFRP) and glass fiber reinforced plastic (GFRP) are used in aerospace and sports equipment.

Challenges: Extremely abrasive; wear out tools quickly; tend to delaminate or splinter.

1.3.3 Ceramics

Engineering ceramics such as alumina and silicon nitride are used where extreme hardness and wear resistance are needed.

Machining: Typically done using grinding, laser cutting, or ultrasonic machining due to extreme hardness.

2. Tool Materials

The cutting tool material is another essential aspect of machining. It must be harder than the workpiece and capable of withstanding high temperatures and wear.

2.1 High-Speed Steel (HSS)

HSS is an alloy of steel with elements such as tungsten, molybdenum, chromium, and vanadium.

Advantages: Tough, inexpensive, and can be easily sharpened.

Applications: Drills, taps, reamers, and low-speed cutting tools.

2.2 Cemented Carbide

Cemented carbides are composed of tungsten carbide (WC) particles bonded with cobalt.

Advantages: High hardness, wear resistance, suitable for high-speed machining.

Limitations: Less tough than HSS; brittle under impact.

2.3 Ceramics

Ceramic tools are made from aluminum oxide or silicon nitride.

Advantages: Very hard, maintain strength at high temperatures, chemically inert.

Limitations: Brittle and prone to chipping under shock or interrupted cuts.

2.4 Cubic Boron Nitride (CBN)

CBN is second only to diamond in hardness and is used for machining hardened steels.

Advantages: Exceptional hardness, thermal stability.

Limitations: Expensive; not suitable for softer materials.

2.5 Polycrystalline Diamond (PCD)

PCD tools are made by sintering diamond particles with a metallic binder.

Advantages: Extremely hard, wear-resistant, ideal for aluminum, plastics, and composites.

Limitations: Reacts with ferrous metals at high temperatures, leading to rapid wear.

3. Material Selection Considerations

Choosing the right material for both workpiece and cutting tool involves evaluating a range of factors.

3.1 Machinability

Machinability refers to how easily a material can be cut. It affects tool life, surface finish, and production costs. Factors include:

Hardness

Ductility

Work-hardening tendency

Thermal conductivity

Chip formation behavior

3.2 Mechanical Properties

For workpiece materials:

Strength and toughness affect how the material behaves under load and how easily it deforms.

Elastic modulus influences dimensional stability.

For tool materials:

Hardness ensures the tool can cut the workpiece without deformation.

Toughness prevents the tool from chipping or breaking.

3.3 Thermal Properties

High thermal conductivity in tool materials helps dissipate heat and prolong tool life.

Low conductivity in workpiece materials like titanium increases the risk of localized heating and tool damage.

3.4 Chemical Reactivity

Chemical interaction between tool and workpiece can lead to tool wear. For instance, aluminum tends to stick to steel tools, while ferrous materials react with diamond tools at high temperatures.

3.5 Cost and Availability

Material cost and availability can influence the choice for both tools and workpieces, especially in high-volume production where efficiency and economics are critical.

4. Recent Advances and Trends

4.1 Coated Tools

Modern machining increasingly relies on coated cutting tools to meet the demands of high-speed, high-precision manufacturing. Tool coatings significantly enhance performance by improving wear resistance, reducing friction, and allowing tools to operate at higher temperatures without degradation. Common coatings include Titanium Nitride (TiN), known for its excellent hardness and golden appearance; Titanium Aluminum Nitride (TiAlN), which provides superior oxidation resistance and performs well in dry machining; and Diamond-Like Carbon (DLC), offering extremely low friction and high wear resistance, ideal for machining non-ferrous metals and plastics. These coatings extend tool life, enhance surface finish, and reduce the need for cutting fluids, leading to more efficient and sustainable operations.

4.2 Superalloys

Nickel-based superalloys, such as Inconel, Hastelloy, and Waspaloy, are engineered to retain strength, corrosion resistance, and stability at extremely high temperatures. These properties make them essential in aerospace, power generation, and medical applications. However, these same characteristics also make them very difficult to machine. They generate high cutting forces, rapidly wear tools, and tend to work-harden, requiring the use of high-performance carbide or ceramic tools, optimized cutting strategies, and advanced cooling systems. Despite these challenges, their ability to maintain mechanical properties under extreme conditions justifies their use in critical components like turbine blades and heat exchangers.

4.3 Additive and Hybrid Manufacturing

Emerging technologies like additive manufacturing (AM) and hybrid machining systems are transforming how materials are processed. Hybrid systems combine additive (3D printing) and subtractive (machining) methods in a single platform, enabling the creation of complex geometries followed by precise finishing. These methods introduce new material combinations and challenges, such as variations in density or surface hardness, demanding innovative tooling solutions and adaptive machining strategies. As this field evolves, it’s redefining material capabilities and machining flexibility in advanced manufacturing.

5. Practical Case Examples

Machining plays a vital role across various high-precision industries, where material selection and tool performance significantly influence product quality and production efficiency.

In the aerospace industry, materials like titanium and aluminum alloys are extensively used due to their excellent strength-to-weight ratios, corrosion resistance, and ability to withstand extreme operating conditions. However, these materials are notoriously difficult to machine. Titanium has low thermal conductivity, leading to high cutting temperatures that can damage tools. Aluminum, though easier to machine, can cause material build-up on the cutting edge. To address these challenges, carbide tools with advanced coatings—such as Titanium Aluminum Nitride (TiAlN)—are employed for their hardness, heat resistance, and durability under high-speed conditions.

In the medical field, implants are commonly made from stainless steel and titanium, chosen for their biocompatibility, corrosion resistance, and mechanical strength. Machining these materials requires extreme precision and care, as surface finish and dimensional accuracy are critical to patient safety and implant functionality. Tools must operate with minimal thermal generation to prevent surface degradation or alterations in material properties. High-quality carbide or ceramic tools are often used, ensuring tight tolerances and smooth finishes suitable for sterile and in-body applications.

The automotive industry focuses on high-efficiency, mass production. Cast iron and aluminum are widely used for engine blocks, cylinder heads, and other structural parts due to their machinability, thermal properties, and cost-effectiveness. These components are machined in highly automated, high-speed environments using durable carbide tools. The emphasis is on tool life, process stability, and consistent part quality across large production runs.

Each sector demands tailored machining strategies and tool materials to meet unique performance, safety, and productivity requirements. Selecting the right combinations of workpiece and tool materials is crucial for success across these diverse manufacturing environments.

Conclusion

Materials in machining are a cornerstone of modern manufacturing. The nature of the workpiece material—its hardness, toughness, thermal properties, and chemical reactivity—directly influences tool selection, machining parameters, and the quality of the final product. Similarly, the choice of cutting tool material determines how efficiently and accurately the workpiece can be shaped.

As technology evolves, the range of materials being machined continues to grow, requiring deeper knowledge and more advanced solutions. With increasing demand for precision, performance, and sustainability, manufacturers must make informed decisions about both workpiece

Related posts:

- Machining and Types of Machining.

- Materials Used in Forging, Chemical Composition, Applications, Examples

- 5-Axis Machining vs 3-Axis Machining – Essential Differences, Applications & Limitations

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses

- 10 Must Have Machine Shop Tools Every Highly Efficient Workshop Needs