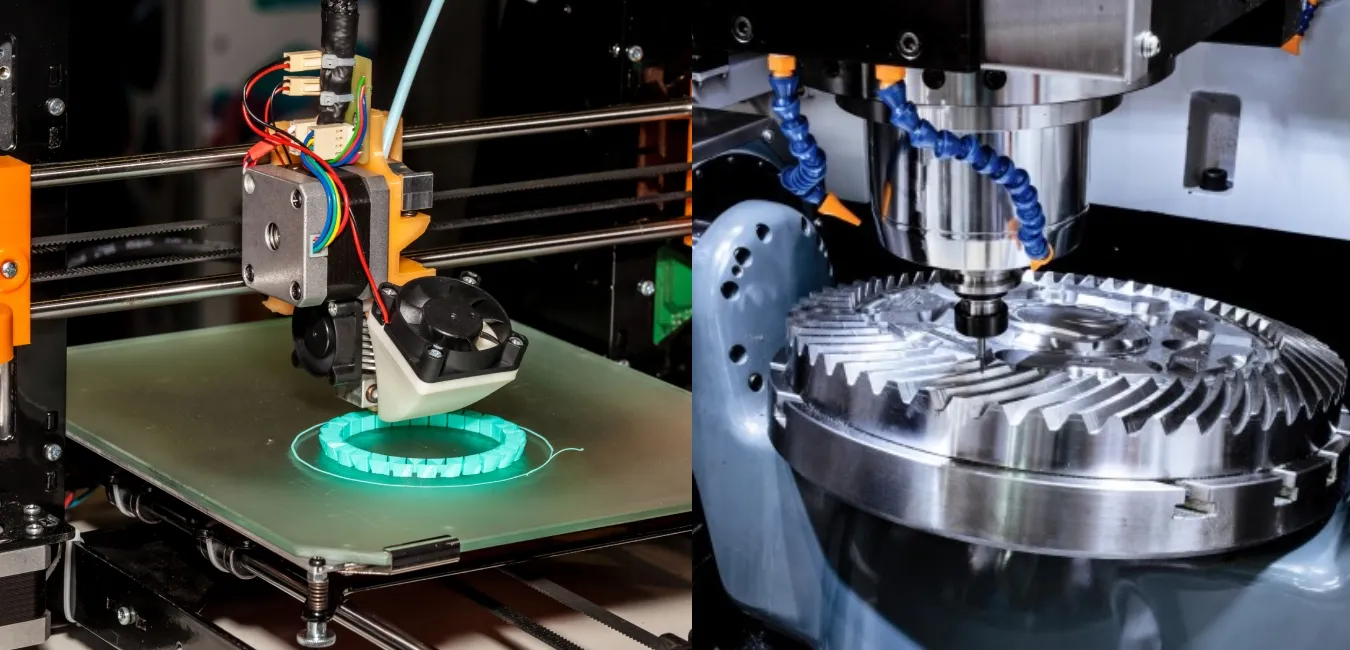

Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on ItLaser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses3D Printing vs Machining: Powerful Comparison of Benefits, Limitations, and Applications10 Must Have Machine Shop Tools Every Highly Efficient Workshop NeedsAdvanced Machining & Automation: 5 Exciting Industry Trends to Watch Introduction to Machining Mistakes Machining is a manufacturing process that involves removing material from a workpiece to achieve desired dimensions and surface finishes. This process is critical across various industries, including aerospace, automotive, and medical fields, where precision and accuracy are paramount. The primary objective of machining is to create parts that not only meet stringent specifications but also enable optimal functionality in their intended applications. However, even the most experienced machinists can encounter challenges that result in common mistakes during the machining process. The significance of precision in machining cannot be overstated; any deviation from the required specifications can lead to severe repercussions. These can range from increased production costs due to material waste, to delays in manufacturing timelines, and ultimately affect product quality. As such, understanding the common errors that may arise during machining is essential for anyone involved in the production process, from operators to engineers. Common mistakes in machining may arise from various factors, including misalignment of tools, incorrect settings on machines, or use of subpar materials. These errors not only compromise the quality of the final product but can also lead to equipment damage and unsafe working conditions. By identifying these pitfalls early on, it becomes possible to implement strategies that can mitigate their effects, enhancing overall manufacturing efficiency. In this blog post, we will explore typical machining mistakes and discuss proactive measures that can be taken to avoid them. By fostering a culture of precision and attention to detail, organizations can significantly improve their machining processes and, consequently, their overall productivity. Understanding and addressing machining mistakes is crucial for maintaining high standards in manufacturing and ensuring the quality of finished products. Mistake #1: Incorrect Tool Selection Choosing the correct cutting tool is a critical aspect of the machining process that can significantly impact productivity, surface finish, and tool life. One of the most common mistakes is selecting the wrong tool for a specific operation or material, which can lead to various complications such as excessive wear, poor dimensional accuracy, and even tool breakage. Understanding the interplay between material properties and tool specifications is essential to avoid these pitfalls. Different materials require specific types of cutting tools to achieve optimal results. For instance, harder materials like titanium or high-strength steels necessitate robust tools that resist wear and deformation. Using a tool that is suited for softer materials on harder workpieces can result in inadequate cutting performance and premature tool failure. Conversely, using an overly aggressive tool on softer materials can lead to poor finishes and reduced machining efficiency. Additionally, the geometry of the cutting tool plays a significant role in its performance. Factors such as rake angle, clearance angle, and cutting edge shape directly influence cutting efficiency and chip formation. Understanding these parameters allows machinists to select the appropriate tool that not only fits the material but also aligns with the specific machining requirements, such as speed and feed rates. To mitigate the risk of incorrect tool selection, machinists should conduct thorough research on the properties of the materials being machined and the specifications of the available tools. Consulting manufacturer datasheets and leveraging available machining software can provide valuable insights. Furthermore, utilizing testing strategies through trial runs can help identify the most effective tool for specific machining conditions, allowing for adjustments before committing to full production runs. Mistake #2: Improper Speed and Feed Rates In machining operations, the correct selection of speed and feed rates is crucial for achieving optimal results. The speed at which a tool moves through the material and the rate at which material is fed into the machine directly influence the machining process. Improperly set speed and feed rates can lead to a range of complications, such as increased tool wear, excessive heat generation, and even tool breakage. Furthermore, they can result in poor surface finishes that may compromise the quality of the final product. Each machining operation, whether it involves turning, milling, or drilling, requires specific speed and feed settings based on the material being processed and the type of tooling used. For instance, harder materials typically require slower speeds and lower feed rates to mitigate the risk of tool damage, while softer materials may allow for faster speeds. Therefore, understanding the material properties is essential in determining the appropriate parameters. Machinists can employ several strategies to identify the correct speed and feed rates. Utilizing manufacturers’ recommendations is a useful starting point; most tool manufacturers provide guidelines tailored to their products. Additionally, machinists can refer to chart resources that list optimal speeds and feeds based on various materials and tooling combinations. Testing different settings through trial runs can also help find the most effective parameters, as real-world results can differ from theoretical calculations. By carefully considering the speed and feed rates in their machining processes, machinists can enhance tool life, improve surface finish quality, and reduce the likelihood of costly disruptions caused by tool failure. It is vital to prioritize these considerations to uphold efficiency and quality in machining tasks. Mistake #3: Failure to Maintain Equipment In the realm of machining, the importance of regular equipment maintenance cannot be overstated. Equipment failures can lead to significant downtime, increased costs, and compromised work quality. Failing to maintain machinery is a prevalent oversight that can severely impact the accuracy of machining processes and the longevity of tools. When tools are not properly maintained, their performance degrades over time, leading to inaccuracies in finished products, inefficiencies, and lost productivity. Regular maintenance schedules are a practical means of ensuring that equipment operates at peak performance. A well-structured maintenance plan typically includes routine inspections, cleaning, lubrication, and calibration. Depending on the equipment’s usage and complexity, maintenance can occur daily,