Machining and Types of Machining.

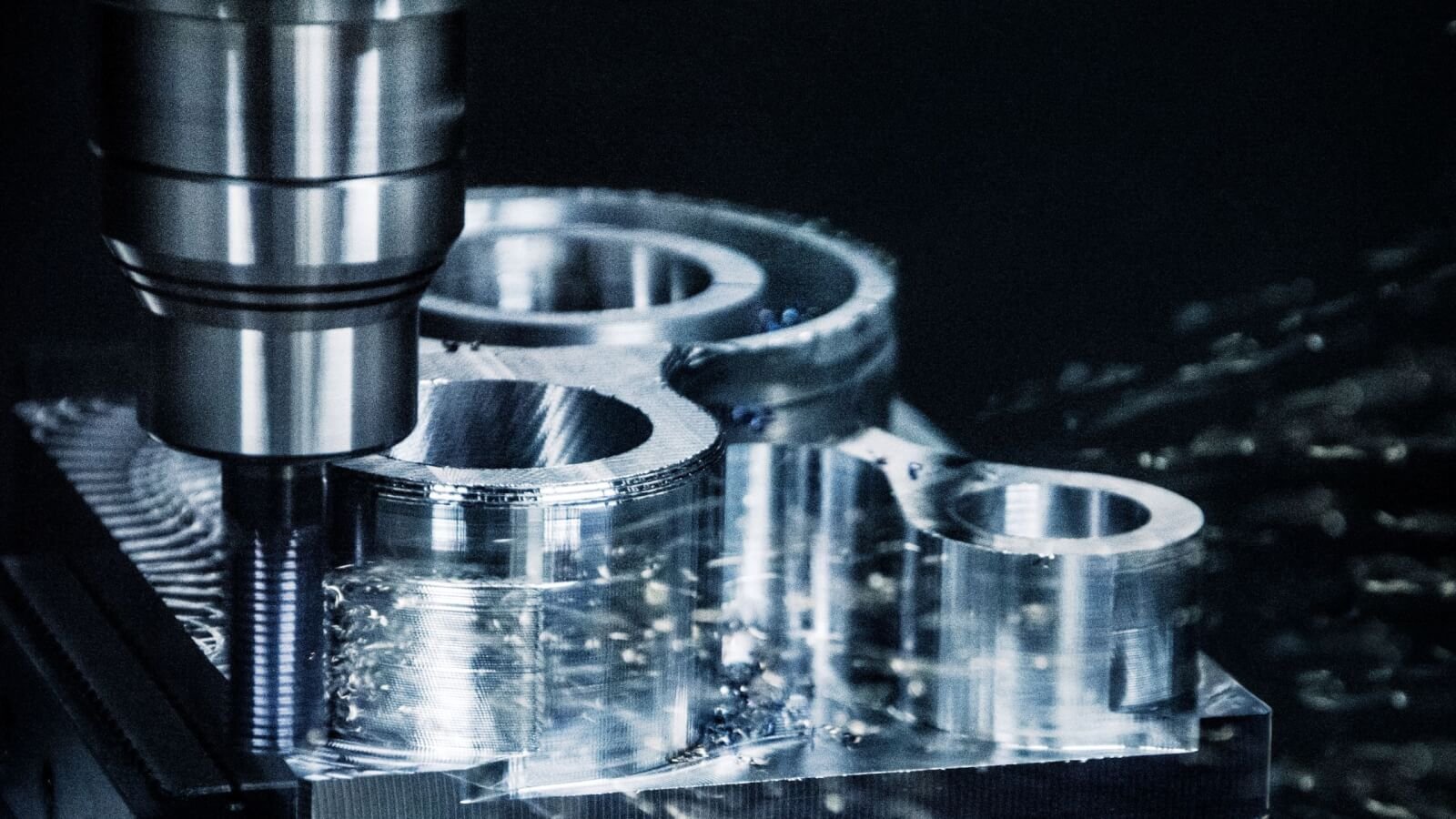

What is Machining? Machining is a manufacturing technique that shapes a workpiece by cutting away excess material using various tools. As a subtractive process, it removes material rather than adding it. This method is commonly employed in industries such as aerospace, automotive, and medical device production due to its precision and versatility. Types of Machining Turning Milling Drilling Grinding Boring Broaching Sawing Electrical Discharge Machining (EDM) Waterjet Cutting Laser Cutting Planing Shaping Honing Lapping Reaming Knurling Ultrasonic Machining (USM) Chemical Machining (CHM) Plasma Arc Machining (PAM) Electron Beam Machining (EBM) Ion Beam Machining (IBM) Cryogenic Machining Know more Turning Turning is a fundamental machining process in which a cutting tool removes material from the surface of a rotating workpiece to form cylindrical shapes. This subtractive process is typically carried out on a lathe, where the cutting tool moves in a straight path while the workpiece spins. Types of Turning Straight TurningRemoves material along the length of the workpiece to produce a uniform diameter. Taper TurningForms a conical shape by gradually reducing the diameter along the length. ProfilingCreates curved or complex external contours on the workpiece. FacingFlattens the end of the workpiece by cutting across its face. Parting (Cut-off)Separates a section of the workpiece by cutting completely through it. GroovingCuts narrow channels or recesses into the outer surface. Thread CuttingProduces helical grooves (threads), commonly used for screws and bolts. BoringEnlarges existing holes with high accuracy and surface finish. Drilling (on a lathe)Uses a stationary drill bit to bore into the center of a rotating workpiece. Applications of Turning Turning is widely used across various industries to manufacture: General Parts: Shafts, bushings, bolts, nuts, pistons Automotive: Engine components, drive shafts, axles Aerospace: Hydraulic rods, fasteners, precision connectors Medical: Orthopedic implants, surgical instruments Industrial: Tooling components, spindles, machine parts Machines Used in Turning Engine LatheManually controlled, versatile for general machining tasks. Turret LatheAllows for quick tool changes and is suitable for batch production. CNC Lathe (Computer Numerical Control)Automated and programmable, ideal for high precision and complex, repetitive tasks. Capstan LatheSimilar to a turret lathe, used for medium-volume work. Bench LatheSmall and compact, used for light-duty tasks and educational purposes. Advantages of Turning High precision and dimensional consistency (especially with CNC) Excellent surface finish quality Adaptable to a variety of shapes and sizes Compatible with many materials including metals, plastics, and composites Straightforward setup and operation Disadvantages of Turning Only suitable for parts with rotational symmetry Generates material waste due to its subtractive nature Manual operation requires skilled machinists Inefficient for producing highly complex, non-cylindrical geometries CNC setups involve higher initial and tooling cost Milling Milling is a machining process that involves a rotating cutting tool removing material from a stationary or moving workpiece. As a subtractive manufacturing method, it is used to produce flat surfaces, slots, holes, and complex 3D shapes. The operation is typically performed on a milling machine, which allows movement along multiple axes (X, Y, and Z) to achieve the desired geometry. Types of Milling Face MillingPrimarily cuts with the end of the cutter, ideal for creating flat surfaces. Peripheral (Slab) MillingCutting occurs along the sides of the tool, used for machining large, flat surfaces parallel to the tool’s axis. End MillingUtilizes end mills for cutting slots, contours, and pockets—well-suited for complex 3D surfaces. Slot MillingInvolves cutting narrow grooves or channels using a slim cutter. Angular MillingPerforms cuts at specific angles to the horizontal plane, used for chamfers or angled surfaces. Form MillingEmploys specially shaped cutters to generate curved or irregular profiles. Gear MillingUses form tools to cut gear teeth profiles accurately. Straddle MillingTwo cutters operate simultaneously on opposite sides of a workpiece to machine two parallel surfaces. Gang MillingInvolves multiple cutters mounted on a single arbor to perform several cuts in one pass. Applications of Milling Milling is widely utilized in various industries for manufacturing components such as: Mechanical Parts: Brackets, housings, engine blocks Tooling Equipment: Molds, dies, jigs, fixtures Automotive Components: Transmission parts, cylinder heads Aerospace Structures: Wing elements, housings, precision fittings Electronics: Heat sinks, device enclosures Medical Devices: Prosthetics, surgical instruments, orthopedic implants Machines Used in Milling Vertical Milling MachineFeatures a vertical spindle; commonly used for face and end milling tasks. Horizontal Milling MachineHas a horizontal spindle, suited for slab and gang milling operations. Universal Milling MachineOffers both vertical and horizontal spindle orientations for enhanced versatility. CNC Milling MachineFully automated and programmable, capable of high-precision and complex multi-axis machining. Manual Milling MachineManually operated, ideal for small-scale projects and prototyping. Bed-Type Milling MachineProvides a fixed workpiece bed for improved stability, used for large or heavy parts. ✅ Advantages of Milling Capable of producing complex geometries and detailed features Supports a wide variety of materials, including metals, plastics, and composites Offers high precision and repeatability, especially with CNC machines Well-suited for flat surface machining, slots, and cavities Multi-axis movement allows for intricate 3D contouring ❌ Disadvantages of Milling Generates material waste due to its subtractive nature Involves more complex setup than simpler operations like turning Less efficient for purely cylindrical parts compared to turning Requires skilled operators or programmers, particularly for CNC systems High initial investment for CNC equipment and tooling Drilling Drilling is a machining process that uses a rotating drill bit to create round holes in a workpiece. As a subtractive method, it’s commonly used for preparing holes for fasteners, fluid flow, or further machining operations. Types of Drilling Standard Drilling – Produces straight, cylindrical holes. Center Drilling – Accurately starts holes to guide deeper drilling. Deep Hole Drilling – Used for holes with high depth-to-diameter ratios. Reaming – Enlarges and finishes existing holes with high precision. Counterboring – Creates a flat-bottom recess for bolt or screw heads. Countersinking – Produces a conical hole entry for flat-head screws. Spot Drilling – Marks

Machining and Types of Machining. Read Post »