Introduction

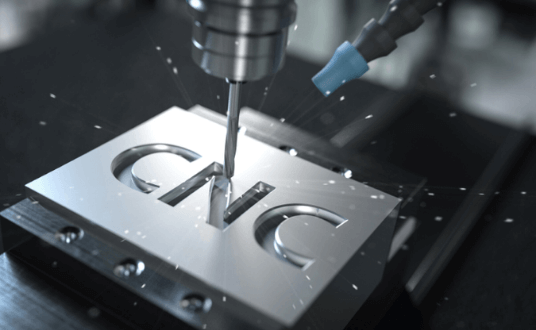

CNC machining is a cornerstone of modern manufacturing, enabling the production of precise, complex parts with minimal human intervention. But what exactly is CNC machining, and why is it so important in today’s industries?

CNC, or Computer Numerical Control, represents a shift from manual craftsmanship to automation-driven precision. It allows manufacturers to fabricate components that meet extremely tight tolerances, which is crucial in industries like aerospace, automotive, and medical device manufacturing. With CNC technology, even the most intricate designs can be executed consistently and efficiently, regardless of batch size.

As demand grows for faster production cycles and higher accuracy, CNC machining has become essential for maintaining competitiveness and innovation. In this article, we’ll explore how CNC machining works, the types of CNC machines available, their advantages, and where they’re used today.

What is CNC Machining?

CNC machining stands for Computer Numerical Control machining, a highly precise and automated manufacturing process that uses computer software to control the movement of machines and cutting tools. Instead of being operated manually, CNC machining relies on pre-programmed code—typically in the form of G-code or M-code—that directs every movement, speed, and toolpath involved in the machining process. This allows CNC machining to cut, drill, mill, grind, or shape a wide variety of materials such as metal, plastic, wood, and composites with outstanding accuracy and repeatability.

The key advantage of CNC machining over traditional manual machining is its level of automation and precision. In manual operations, human operators control the tools by hand, which increases the chance of variability and error. CNC machining removes these risks by executing exact instructions from a digital design file, ensuring that every part produced is consistent, accurate, and reliable. Whether used for prototyping or full-scale production, CNC machining is ideal for manufacturing complex components with tight tolerances and is widely used across industries such as aerospace, automotive, electronics, and medical.

How CNC Machining Works

The CNC machining process follows a structured workflow that transforms a digital idea into a physical part with precision and repeatability. Here’s a closer look at each step involved:

1. Design (CAD – Computer-Aided Design)

The first step in CNC machining begins with a detailed part design, created using CAD software such as AutoCAD, SolidWorks, or Fusion 360. Engineers and designers develop a 2D drawing or 3D model, specifying critical features like dimensions, geometry, tolerances, and materials. This design serves as the digital blueprint for the final product. It’s essential that the CAD model is accurate and complete, as it forms the foundation for all subsequent steps.

2. CAM Programming (Computer-Aided Manufacturing)

Once the design is finalized, it’s imported into CAM software, which translates the CAD model into machine-readable code—typically G-code or M-code. CAM programming defines the toolpaths, cutting operations, feed rates, and spindle speeds required to produce the part. This stage is crucial for optimizing machining efficiency and avoiding tool collisions or errors during operation. Many CAM platforms also simulate the machining process virtually to detect issues before physical production begins.

3. Machine Setup

After the program is generated, it is uploaded into the CNC machine’s controller. The machine operator then prepares the workspace by securing the raw material (or workpiece) onto the machine bed using fixtures, clamps, or vises. Correct alignment and calibration of the machine axes and tooling are verified at this stage to ensure accurate production. Tool selection and tool changes are also configured based on the machining requirements.

4. Machining

With everything in place, the CNC machine begins executing the programmed toolpaths. Depending on the design, the machine may perform multiple operations such as milling, drilling, turning, or tapping. The machine moves precisely along multiple axes, removing material layer by layer to achieve the desired shape and specifications. This process is typically automated, requiring minimal human intervention unless a tool needs to be replaced or an error occurs.

5. Finishing & Inspection

Once machining is complete, the part undergoes finishing operations, which may include deburring, sanding, polishing, or surface treatment to improve appearance or performance. The final step is quality control, where the part is inspected for dimensional accuracy, surface finish, and overall conformity using tools such as calipers, micrometers, CMM (Coordinate Measuring Machine), or laser scanners. Only parts that pass inspection are approved for delivery or assembly.

Types of CNC Machines

CNC (Computer Numerical Control) technology is applied to a wide range of machines, each serving a specific purpose based on the material, required operation, and complexity of the part. Understanding the different types of CNC machines is key to choosing the right one for a given manufacturing task. Below is a detailed look at the most commonly used CNC machines, along with their functions and typical applications:

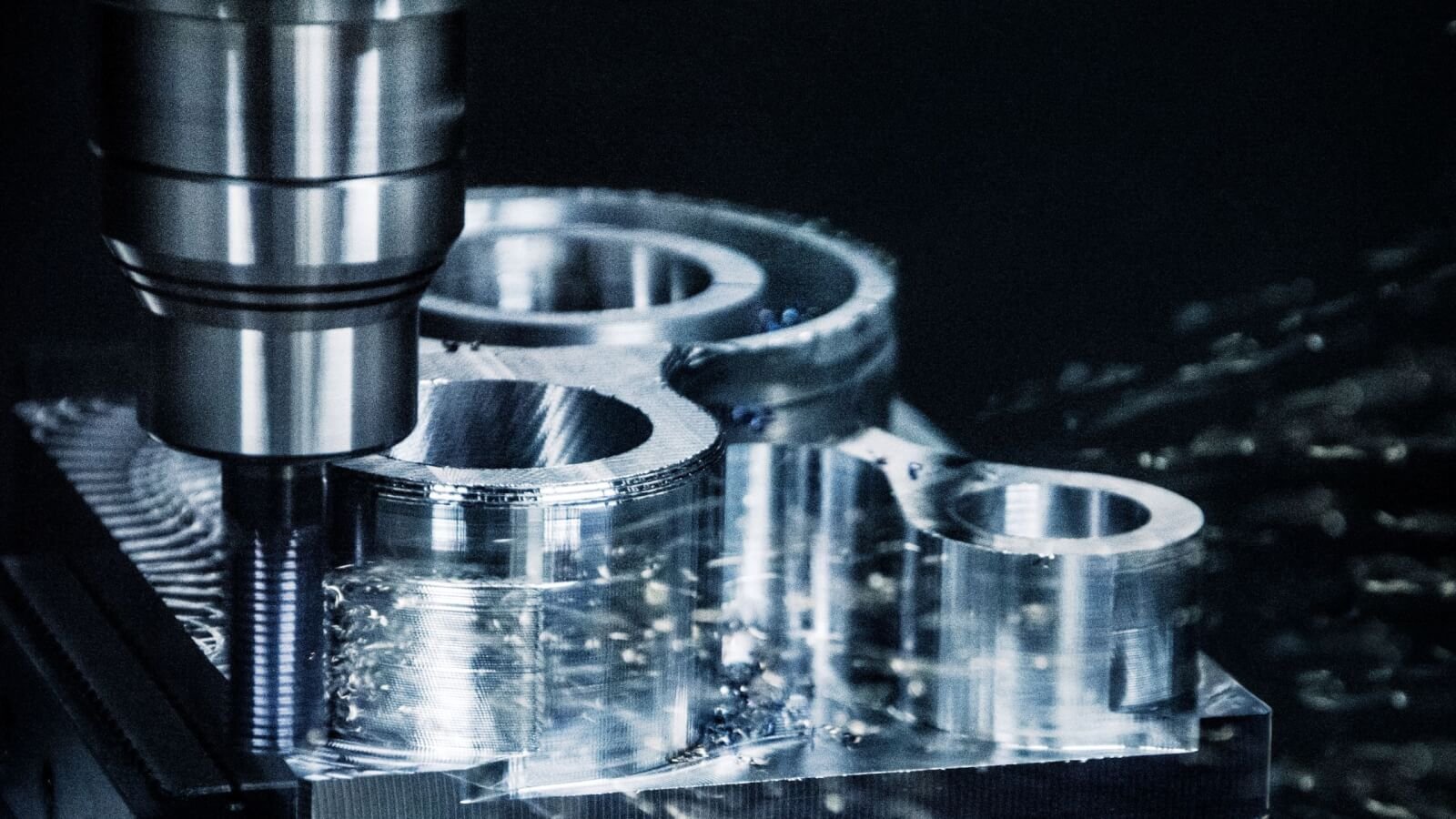

1. CNC Milling Machines

CNC milling machines are among the most commonly used CNC equipment in manufacturing. These machines use rotating multi-point cutting tools to progressively remove material from a fixed workpiece. They can operate on multiple axes—commonly 3, 4, or 5 axes—which allows them to produce intricate and multi-dimensional parts with high accuracy.

Applications: CNC milling is widely used in the aerospace, automotive, and medical industries to produce engine components, structural parts, custom enclosures, molds, and dies.

2. CNC Lathes (Turning Centers)

CNC lathes operate by rotating the workpiece against a stationary, single-point cutting tool. They are ideal for creating symmetrical parts such as cylinders, cones, or threads. Modern CNC lathes often include live tooling (milling tools) and sub-spindles, allowing multiple operations in a single setup.

Applications: Common in producing shafts, bushings, bolts, and other round parts, CNC lathes are widely used in automotive, oil and gas, and heavy equipment manufacturing.

3. CNC Routers

CNC routers are similar to milling machines but are typically used to cut softer materials like wood, plastic, foam, and aluminum. They are popular for producing complex shapes, engravings, signage, and furniture components. CNC routers operate at higher speeds but generally apply lower cutting forces.

Applications: Woodworking, sign-making, cabinetry, and composite material fabrication.

4. CNC Plasma Cutters

CNC plasma cutters use a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials, mainly metals like steel, aluminum, and brass. These machines are highly efficient for cutting thick metal plates and are commonly used in fabrication shops.

Applications: Metal art, HVAC ductwork, structural steel cutting, and industrial equipment production.

5. CNC EDM (Electrical Discharge Machines)

EDM machines use electrical discharges or sparks to erode material from a workpiece. There are two main types: Wire EDM, which uses a thin wire to cut through material, and Sinker EDM, which uses an electrode to shape complex cavities.

Applications: Ideal for hard metals and intricate geometries, EDM is used in mold-making, aerospace tooling, and precision die manufacturing.

6. CNC Grinders

CNC grinding machines use abrasive wheels to precisely grind surfaces, edges, or contours. These machines offer exceptional surface finishes and tight tolerances and are essential for polishing and final shaping.

Applications: Tool sharpening, bearing surface finishing, medical implants, and high-performance engine parts.

7. CNC Laser Cutters

Though not in the original list, CNC laser cutters deserve mention. These machines use focused laser beams to melt, burn, or vaporize material with precision. They are highly effective for detailed cuts in thin materials.

Applications: Electronics, jewelry, sheet metal processing, and artistic metalwork.

Advantages of CNC Machining

CNC (Computer Numerical Control) machining has transformed modern manufacturing by delivering precision, consistency, and efficiency that manual methods can’t match. Below are five key advantages, explained in depth:

1. High Precision and Accuracy

CNC machines operate with exceptionally tight tolerances, often within ±0.001 inches or better. This level of accuracy is achieved by precisely controlled movements along multiple axes, guided by digital instructions. The result is components that meet exact specifications without deviation—critical for industries like aerospace, medical, and electronics where even the smallest discrepancy can compromise performance or safety.

2. Repeatability

Once a CNC program is validated, it can be used to produce an identical part over and over again. This repeatability ensures consistency across batches, which is vital for applications requiring interchangeable or standardized parts. Whether producing 10 or 10,000 components, CNC machining guarantees that every unit meets the same dimensional and quality standards.

3. Increased Productivity

CNC machines can operate continuously with minimal supervision, even overnight or during weekends. Features like automatic tool changers, multi-axis capabilities, and real-time monitoring systems further enhance throughput. Complex parts that would require multiple manual setups can often be completed in a single automated cycle, reducing production time significantly.

4. Reduced Human Error

By automating the cutting process, CNC machining reduces the possibility of errors that commonly occur in manual operations—such as misalignment, incorrect feed rates, or inconsistent measurements. The reliance on software programming rather than manual input also enhances workplace safety and reduces waste.

5. Scalability

CNC machining is ideal for both rapid prototyping and mass production. During development, engineers can test and revise designs quickly. Once finalized, the same program can scale up to high-volume production with no loss in quality—making it a flexible and cost-effective solution for businesses of any size.

Industries Using CNC Machining

CNC machining serves a wide range of industries that demand high precision, repeatability, and material versatility. Here’s how it benefits each sector:

Aerospace

Produces high-precision components for engines, turbines, and structural parts.

Common parts include turbine blades, landing gear, brackets, and airframe components.

Often machines tough materials like titanium and aluminum alloys.

Ensures compliance with strict safety and regulatory standards.

Automotive

Manufactures engine blocks, pistons, gearboxes, and custom wheels.

Supports both mass production and prototyping for new model development.

Delivers consistent quality for critical performance and safety components.

Enables customization for aftermarket and performance parts.

Medical

Creates implants, such as hip joints, spinal rods, and dental implants.

Machines surgical instruments, including scalpels, forceps, and drills.

Produces custom prosthetics and orthopedic supports.

Works with biocompatible materials like titanium, stainless steel, and PEEK.

Meets strict cleanroom and hygiene standards.

Electronics

Fabricates aluminum and plastic housings for devices.

Produces precision connectors, mounts, and heat sinks.

Enables miniaturization for compact, high-density circuit layouts.

Supports rapid prototyping for device enclosures and hardware components.

Defense

Machines weapons components, such as barrels, triggers, and mounts.

Produces armor plating and vehicle parts for tanks and personnel carriers.

Used for drone parts, surveillance systems, and optical mounts.

Ensures consistent quality for mission-critical applications.

Related posts:

- 5-Axis Machining vs 3-Axis Machining – Essential Differences, Applications & Limitations

- 3D Printing vs Machining: Powerful Comparison of Benefits, Limitations, and Applications

- Machining and Types of Machining.

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses