Introduction to Machining Mistakes

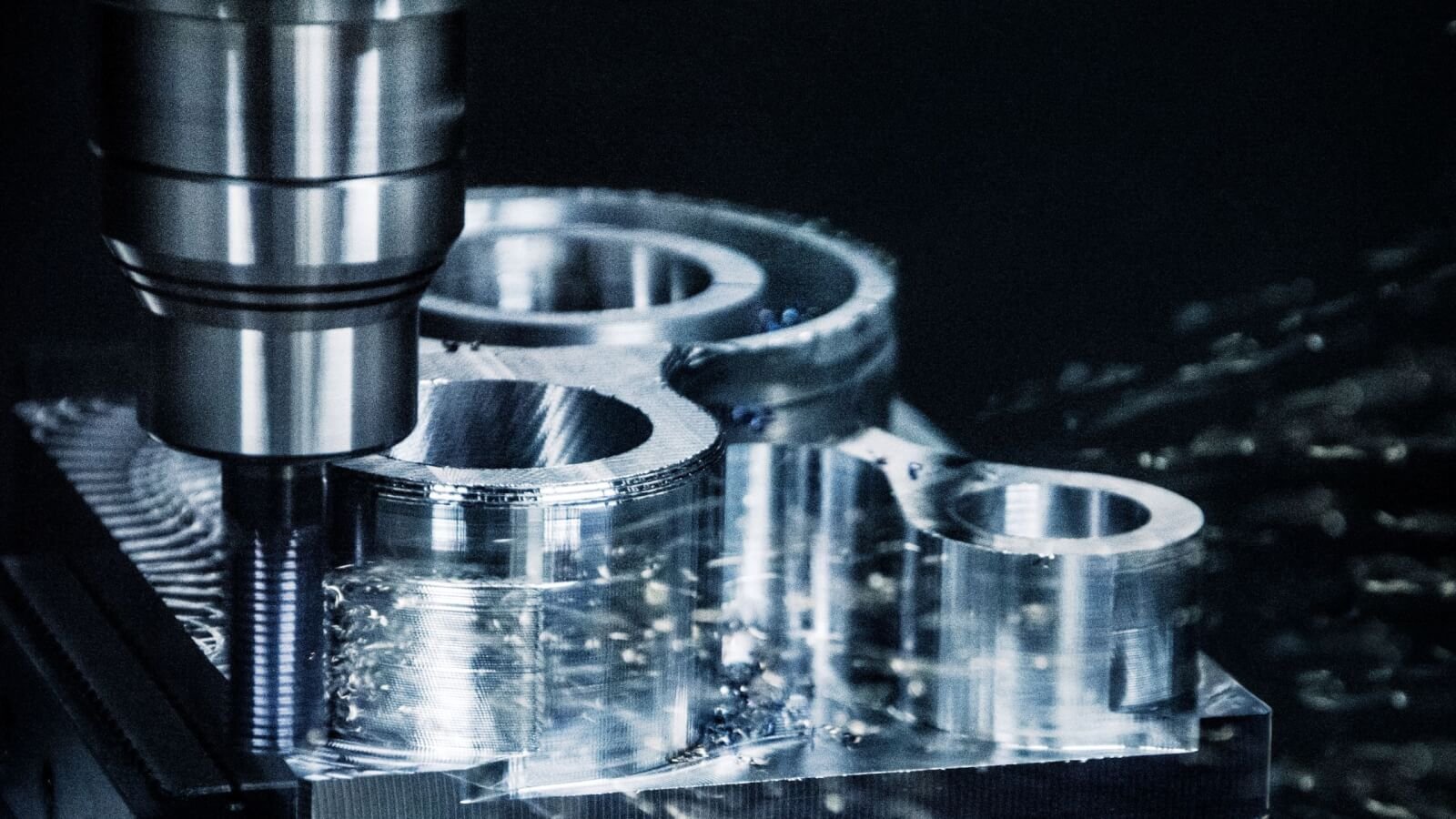

Machining is a manufacturing process that involves removing material from a workpiece to achieve desired dimensions and surface finishes. This process is critical across various industries, including aerospace, automotive, and medical fields, where precision and accuracy are paramount. The primary objective of machining is to create parts that not only meet stringent specifications but also enable optimal functionality in their intended applications. However, even the most experienced machinists can encounter challenges that result in common mistakes during the machining process.

The significance of precision in machining cannot be overstated; any deviation from the required specifications can lead to severe repercussions. These can range from increased production costs due to material waste, to delays in manufacturing timelines, and ultimately affect product quality. As such, understanding the common errors that may arise during machining is essential for anyone involved in the production process, from operators to engineers.

Common mistakes in machining may arise from various factors, including misalignment of tools, incorrect settings on machines, or use of subpar materials. These errors not only compromise the quality of the final product but can also lead to equipment damage and unsafe working conditions. By identifying these pitfalls early on, it becomes possible to implement strategies that can mitigate their effects, enhancing overall manufacturing efficiency.

In this blog post, we will explore typical machining mistakes and discuss proactive measures that can be taken to avoid them. By fostering a culture of precision and attention to detail, organizations can significantly improve their machining processes and, consequently, their overall productivity. Understanding and addressing machining mistakes is crucial for maintaining high standards in manufacturing and ensuring the quality of finished products.

Mistake #1: Incorrect Tool Selection

Choosing the correct cutting tool is a critical aspect of the machining process that can significantly impact productivity, surface finish, and tool life. One of the most common mistakes is selecting the wrong tool for a specific operation or material, which can lead to various complications such as excessive wear, poor dimensional accuracy, and even tool breakage. Understanding the interplay between material properties and tool specifications is essential to avoid these pitfalls.

Different materials require specific types of cutting tools to achieve optimal results. For instance, harder materials like titanium or high-strength steels necessitate robust tools that resist wear and deformation. Using a tool that is suited for softer materials on harder workpieces can result in inadequate cutting performance and premature tool failure. Conversely, using an overly aggressive tool on softer materials can lead to poor finishes and reduced machining efficiency.

Additionally, the geometry of the cutting tool plays a significant role in its performance. Factors such as rake angle, clearance angle, and cutting edge shape directly influence cutting efficiency and chip formation. Understanding these parameters allows machinists to select the appropriate tool that not only fits the material but also aligns with the specific machining requirements, such as speed and feed rates.

To mitigate the risk of incorrect tool selection, machinists should conduct thorough research on the properties of the materials being machined and the specifications of the available tools. Consulting manufacturer datasheets and leveraging available machining software can provide valuable insights. Furthermore, utilizing testing strategies through trial runs can help identify the most effective tool for specific machining conditions, allowing for adjustments before committing to full production runs.

Mistake #2: Improper Speed and Feed Rates

In machining operations, the correct selection of speed and feed rates is crucial for achieving optimal results. The speed at which a tool moves through the material and the rate at which material is fed into the machine directly influence the machining process. Improperly set speed and feed rates can lead to a range of complications, such as increased tool wear, excessive heat generation, and even tool breakage. Furthermore, they can result in poor surface finishes that may compromise the quality of the final product.

Each machining operation, whether it involves turning, milling, or drilling, requires specific speed and feed settings based on the material being processed and the type of tooling used. For instance, harder materials typically require slower speeds and lower feed rates to mitigate the risk of tool damage, while softer materials may allow for faster speeds. Therefore, understanding the material properties is essential in determining the appropriate parameters.

Machinists can employ several strategies to identify the correct speed and feed rates. Utilizing manufacturers’ recommendations is a useful starting point; most tool manufacturers provide guidelines tailored to their products. Additionally, machinists can refer to chart resources that list optimal speeds and feeds based on various materials and tooling combinations. Testing different settings through trial runs can also help find the most effective parameters, as real-world results can differ from theoretical calculations.

By carefully considering the speed and feed rates in their machining processes, machinists can enhance tool life, improve surface finish quality, and reduce the likelihood of costly disruptions caused by tool failure. It is vital to prioritize these considerations to uphold efficiency and quality in machining tasks.

Mistake #3: Failure to Maintain Equipment

In the realm of machining, the importance of regular equipment maintenance cannot be overstated. Equipment failures can lead to significant downtime, increased costs, and compromised work quality. Failing to maintain machinery is a prevalent oversight that can severely impact the accuracy of machining processes and the longevity of tools. When tools are not properly maintained, their performance degrades over time, leading to inaccuracies in finished products, inefficiencies, and lost productivity.

Regular maintenance schedules are a practical means of ensuring that equipment operates at peak performance. A well-structured maintenance plan typically includes routine inspections, cleaning, lubrication, and calibration. Depending on the equipment’s usage and complexity, maintenance can occur daily, weekly, or monthly. For instance, CNC machines should undergo daily checks for cleanliness and lubrication, while more comprehensive inspections might be necessary on a monthly or quarterly basis. Incorporating these tasks into the workflow enhances the reliability of the machinery, thus reducing the likelihood of unexpected breakdowns.

Additionally, training operators on proper maintenance techniques can be invaluable. Operators should be knowledgeable about the specific needs of the machinery they work with, and training programs can help ensure the correct practices are understood and implemented. For example, operators should be familiar with the signs of wear and tear that indicate when a tool needs to be replaced or serviced. Cultivating a culture of maintenance within a machining facility can lead to significant improvements in both efficiency and product quality.

By prioritizing equipment maintenance and integrating it into daily practices, machining operations can avoid the pitfalls associated with neglecting crucial upkeep. Properly maintained equipment not only ensures precision in machining but also prolongs the lifespan of valuable tools, ultimately leading to enhanced productivity and reduced costs over time.

Mistake #4: Neglecting Workpiece Setup

Proper workpiece setup and alignment are fundamental aspects of machining that can significantly affect the quality of the final product. Neglecting this crucial step can lead to various problems, including tolerances being out of specification, resulting in components that do not meet design requirements. When a workpiece is misaligned, the cutting tools may not engage completely, leading to uneven wear, increased tool breakage, and suboptimal machining performance.

One of the primary challenges in achieving correct workpiece setup is the difficulty in maintaining proper alignment during the machining process. The use of ineffective workholding techniques can exacerbate this issue, causing parts to shift or vibrate, which further compromises precision. To avoid such problems, it is essential to employ robust workholding solutions, such as vises or fixtures that secure the workpiece firmly in place. Using appropriate clamps or straps allows for stability and minimizes movement, ensuring repeated accuracy in subsequent operations.

Additionally, utilizing measurement tools is vital to confirming alignment prior to commencing any machining operations. Tools such as dial indicators or laser alignment systems provide the necessary feedback to ensure that the workpiece is correctly positioned. Performing regular checks during machining can also help identify any deviations from the intended setup, allowing for timely adjustments before extensive machining occurs. Regular calibration and maintenance of measurement tools is also essential to enhance their reliability.

In summary, to avoid the mistakes associated with neglecting workpiece setup, it is crucial to prioritize effective workholding and measurement techniques. Regularly evaluating the alignment and stability of components will ensure that machining processes remain efficient and produce high-quality, accurate results.

Mistake #5: Ignoring Cooling and Lubrication Needs

In the machining process, proper cooling and lubrication are critical factors that significantly influence operational efficiency and product quality. Ignoring these essential needs can lead to a series of detrimental outcomes, including increased wear on cutting tools, compromised surface finishes, and the risk of heat-induced material failures. The primary function of coolant is to reduce friction and heat generation during the machining operations, which in turn extends the life of the cutting tools and enhances overall performance.

When machining metals and other materials, high temperatures generated by friction can result in thermal deformation and tool dulling, necessitating more frequent tool changes and increasing production costs. Additionally, insufficient lubrication can lead to poor chip removal, resulting in built-up edge (BUE) formation and negatively impacting the dimensional accuracy of the components being manufactured. It is crucial for machinists to recognize the role that proper cooling and lubrication play in maintaining the integrity of the machining process.

Choosing the right cooling and lubrication methods is dependent on various factors, including the type of material being machined, the cutting tool geometry, and the specific machining operation. Common cooling fluids include water-soluble oils, synthetic coolants, and straight oils, each offering distinct advantages based on the machining environment. For instance, water-soluble oils are often recommended for high-speed machining, while straight oils may be preferred for heavier cutting applications.

Moreover, implementing a structured approach to evaluate the performance of cooling and lubrication can provide insights into potential improvements in the machining cycle. Regular monitoring and adjustment of coolant flow rates, temperatures, and properties ensure they remain effective in their respective roles. Adopting best practices in cooling and lubrication not only minimizes common machining mistakes but also maximizes productivity and quality outcomes.

Mistake #6: Overlooking Safety Protocols

In the machining industry, overlooking safety protocols represents a significant mistake that can result in dire consequences for both machinists and equipment. The machining environment presents various hazards, including exposure to sharp tools, heavy machinery, and toxic substances. The neglect of safety measures not only poses a risk to the physical well-being of personnel but also threatens the integrity of the machines being operated.

Machinists functioning in an unsafe environment may face incidents ranging from minor injuries to life-threatening accidents. For instance, without proper personal protective equipment (PPE), such as gloves, goggles, and ear protection, workers increase their vulnerability to accidents. Furthermore, inadequate training regarding the safe operation of machinery can exacerbate these risks, leading to improper handling and potential injuries. Therefore, it is imperative that safety protocols be diligently followed to mitigate these risks.

Implementing effective safety practices begins with fostering a culture of safety within the workplace. This can be accomplished through comprehensive training programs that emphasize the importance of adhering to established safety procedures. Encouraging machinists to regularly participate in safety drills and discussions can further instill the significance of these practices. Regular audits and assessments of the workspace should also be conducted to identify potential hazards and ensure compliance with safety standards.

Additionally, providing accessible safety resources, such as signage to remind workers of proper practices and procedures, can enhance awareness. It is essential for facilities to maintain clear communication channels, enabling employees to report unsafe conditions or near-miss incidents without fear of reprisal. By actively promoting a safety-first mindset and taking the necessary precautions, machining environments can effectively reduce the likelihood of accidents and create a safer workplace.

Mistake #7: Insufficient Quality Control Measures

Quality control is a critical component of the machining process, serving as the backbone for ensuring precision and reliability in the production of components. Insufficient quality control measures can lead to significant issues, including the production of defective parts, increased waste, and damage to the reputation of the manufacturer. These negative consequences stem from the inability to identify and rectify errors before they escalate into larger problems.

To mitigate the risks associated with inadequate quality control, manufacturers should implement a comprehensive quality assurance framework. This framework may include a combination of methods such as statistical process control (SPC), which allows for real-time monitoring of machining processes. By analyzing data collected during production, manufacturers can detect trends that may indicate potential quality issues. Additionally, visual inspections and gauge measurements are essential for verifying that manufactured parts meet predefined specifications.

Regular inspections during various manufacturing stages can also uncover discrepancies that might otherwise go unnoticed. Instituting a system of checks at different points in the machining process enhances the overall quality of the produced parts. Employing techniques such as in-process inspection and end-of-line testing can significantly reduce the likelihood of defects. Furthermore, the use of advanced imaging technologies can assist in identifying surface imperfections that may compromise part integrity.

Training employees in quality control methods will also significantly contribute to reducing errors in machining. Engaging the workforce in understanding the importance of quality assurance principles ensures that everyone is committed to maintaining high standards. By fostering a culture of quality and accountability, companies can enhance their machining processes and deliver products that meet or exceed client expectations.

Mistake #8: Failing to Embrace Continuous Improvement

In the machining industry, the importance of continuous improvement cannot be overstated. One major mistake that machinists often make is failing to adapt their practices over time, which can lead to recurring issues and inefficiencies. Continuous improvement involves an ongoing effort to enhance processes, quality, and performance by making incremental changes based on feedback and data analysis. Without this commitment to evolution, professionals may find themselves trapped in a cycle of repeated errors, affecting overall productivity and quality.

Embracing continuous improvement requires a proactive approach to identifying areas that need enhancement. One effective method is to implement regular reviews of production processes, where techniques and outcomes are scrutinized. By analyzing data related to machining operations, such as cycle times, error rates, and tool wear, machinists can pinpoint specific challenges. This analytical process fosters a culture of accountability and encourages team members to voice concerns and propose solutions that can streamline operations.

Additionally, it is crucial for machinists to stay updated with industry trends and advancements in technology. Innovations such as automation and advanced tooling can offer significant improvements in machining efficiency and precision. By attending training sessions, workshops, and industry conferences, technicians can learn about new methodologies and tools. Integrating these developments into existing practices can reduce the likelihood of mistakes and bolster overall performance.

Overall, the commitment to continuous improvement in machining practices not only enhances the quality of the output but also cultivates a more engaged and knowledgeable workforce. By fostering an environment where feedback is welcomed and adaptations are made, professionals can significantly minimize recurring errors and elevate their operational standards.

Conclusion: Building a Culture of Precision in Machining

In the realm of machining, the importance of precision cannot be overstated. Throughout this blog post, we have outlined some of the most common mistakes encountered within the industry, including issues related to tool selection, machine calibration, and workflow inefficiencies. Each of these errors not only leads to defective products but also adversely affects operational costs and timelines. It is essential for both machinists and manufacturers to recognize these pitfalls and understand their underpinnings to ensure a more streamlined and effective machining process.

Moreover, fostering a culture of precision in machining goes beyond merely correcting individual mistakes. It necessitates an organizational commitment to continuous improvement and learning. Organizations must encourage open communication among team members, ensuring that everyone is empowered to voice concerns and propose solutions. This collective mindset promotes a proactive approach to error identification and rectification.

Training and education play a critical role in this development. By investing in regular training programs and workshops, organizations can keep their workforce updated on the latest machining technologies and best practices. Furthermore, adopting modern tools and software for monitoring and quality assurance can greatly reduce errors while enhancing overall efficiency in machining processes.

Emphasizing mindfulness in every step—from planning and execution to review—can significantly mitigate mistakes. By incorporating careful analysis and encouraging team members to reflect on their work, machinists can cultivate a more meticulous approach that prioritizes accuracy over speed. Hence, creating a culture that values precision not only aids in minimizing mistakes but also enhances the overall quality of products manufactured. Ultimately, the commitment to learning from past mistakes and investing in improvement will lead to more reliable and refined machining outcomes.

Related posts:

- Machining and Types of Machining.

- 5-Axis Machining vs 3-Axis Machining – Essential Differences, Applications & Limitations

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses

- 10 Must Have Machine Shop Tools Every Highly Efficient Workshop Needs

- Advanced Machining & Automation: 5 Exciting Industry Trends to Watch