Introduction

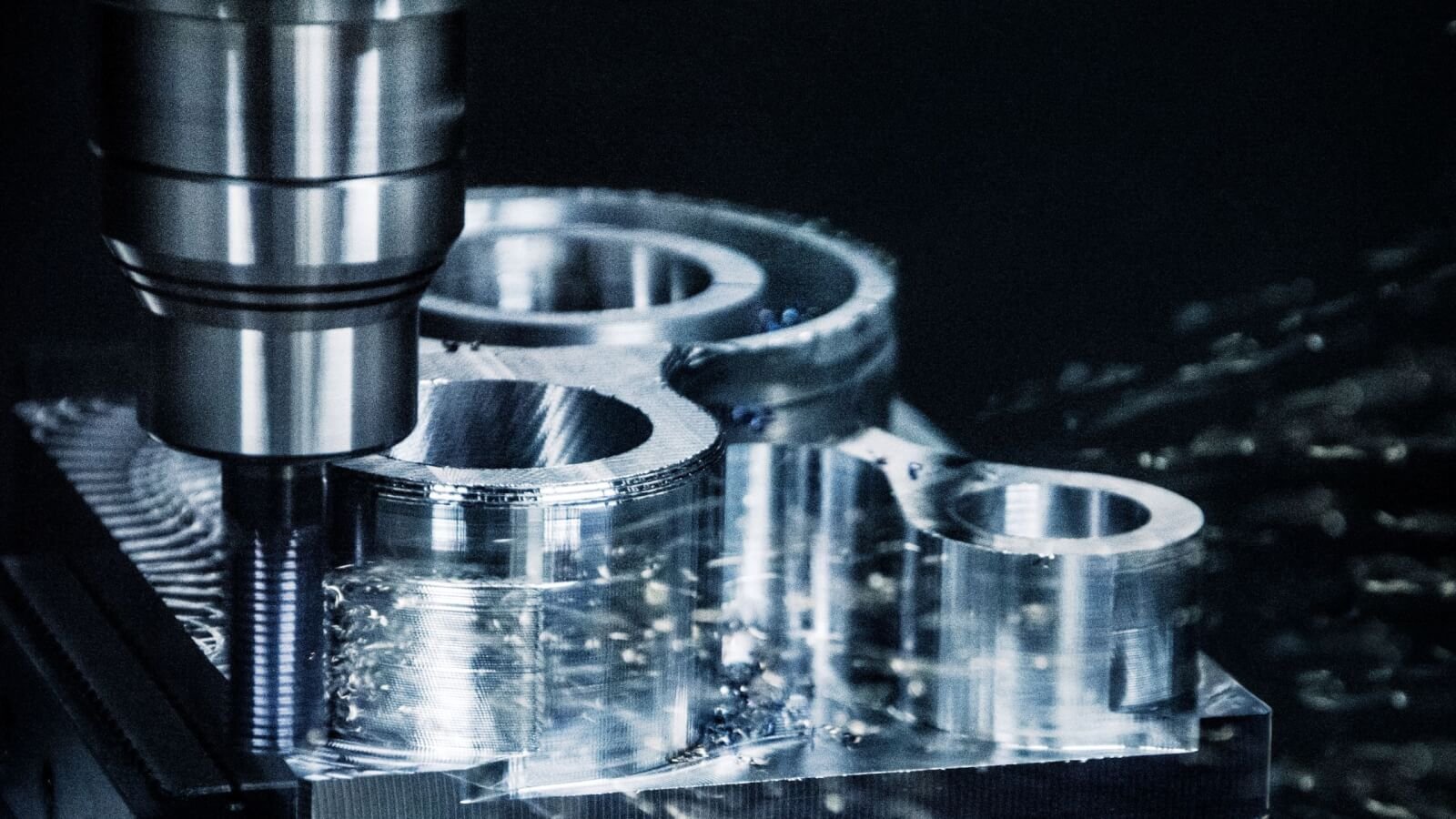

Machining is a foundational process in manufacturing, encompassing operations such as turning, milling, drilling, grinding, and broaching. In these operations, metal is removed from a workpiece using cutting tools to achieve desired shapes, dimensions, and surface finishes. One of the critical elements that significantly influences machining efficiency, tool life, product quality, and operational cost is the use of cutting fluids in machining.

Cutting fluids, often referred to as coolants or lubricants, are specialized liquids or gases applied during machining to achieve specific performance improvements. Their primary purpose is to reduce friction, dissipate heat, enhance tool life, and produce a higher-quality finished product. With advancements in materials and technology, cutting fluid formulations have evolved to meet specific requirements across industries.

This article explores the types of cutting fluids used in machining, their respective functions, and how they contribute to improving machining quality. It also examines selection criteria, environmental considerations, and future trends.

Importance of Cutting Fluids in Machining

Cutting fluids serve several critical functions in the machining process, including:

1. Cooling

During machining, the interaction between the tool and workpiece generates a significant amount of heat due to plastic deformation and friction. If not properly controlled, excessive heat can lead to:

Dimensional inaccuracies due to thermal expansion.

Tool wear or breakage.

Workpiece surface damage, such as burns or microstructural changes.

Cutting fluids absorb and carry away this heat, maintaining a stable temperature in the cutting zone and improving thermal management.

2. Lubrication

By reducing friction at the interface between the cutting tool and workpiece or chip, cutting fluids minimize adhesive wear and lower the forces required for cutting. Lubrication also improves the surface finish and helps prevent built-up edge (BUE) formation on the cutting tool.

3. Chip Removal

Effective chip evacuation is essential to prevent recutting, tool breakage, and surface damage. Cutting fluids help wash away chips from the cutting zone, especially in high-speed or deep-hole operations like drilling or boring.

4. Surface Finish Improvement

By reducing friction and temperature fluctuations, cutting fluids help achieve smoother surface finishes. This is especially critical for precision parts in aerospace, automotive, and medical industries.

5. Corrosion Inhibition

Some cutting fluids are formulated with rust inhibitors that protect both the tool and the workpiece from oxidation, particularly when the fluid contains water.

6. Extension of Tool Life

Minimized friction and reduced thermal stress help in extending the life of cutting tools, resulting in fewer replacements, lower costs, and less downtime.

Classification and Types of Cutting Fluids

Cutting fluids are broadly categorized based on their composition, physical form, and method of application. The major types are:

1. Water-Based Fluids

These fluids primarily consist of water, the best known heat-transfer medium. However, additives are often required to enhance lubrication, inhibit rust, and prevent microbial growth.

Soluble Oils (Emulsions)

Soluble oils consist of mineral oils emulsified in water with the help of emulsifiers. When mixed with water, they form a milky emulsion.

Composition: 5-20% mineral oil + emulsifiers + water.

Advantages:

Good cooling properties.

Economical for general use.

Some lubricity for moderate operations.

Disadvantages:

Susceptible to bacterial contamination.

Requires regular maintenance and monitoring.

Applications: Turning, milling, light to moderate-duty machining.

Semi-Synthetic Fluids

These are a combination of soluble oils and synthetic fluids, offering balanced cooling and lubrication.

Advantages:

Better stability and cleanliness compared to emulsions.

Reduced microbial growth.

Improved corrosion resistance.

Applications: Versatile use in automotive, aerospace, and general manufacturing.

Synthetic Fluids

Synthetic fluids are completely oil-free and made from chemical solutions (e.g., glycol-based compounds).

Advantages:

Excellent cooling capacity.

Low residue and cleaner working conditions.

Environmentally safer and more stable.

Disadvantages:

Poor lubricating ability unless specially formulated.

Applications: High-speed grinding, aluminum and titanium machining.

2. Oil-Based Fluids

Also known as straight oils, these fluids are made entirely from mineral or synthetic oils and often contain additives for enhanced performance.

Straight Cutting Oils

Straight oils provide superior lubrication, often used without dilution.

Composition: Mineral or synthetic oil + extreme pressure (EP) additives like sulfur, chlorine, or phosphorus.

Advantages:

Excellent lubricity.

Reduced tool wear in heavy-duty operations.

Disadvantages:

Poor cooling.

Can generate smoke and foul odor.

Fire hazard in high-speed machining.

Applications: Tapping, broaching, gear cutting, deep-hole drilling.

3. Gaseous and Cryogenic Fluids

Compressed Air

Used as a dry machining aid, mainly for chip removal and minimal cooling.

Advantages:

Clean process.

Environmentally friendly.

Disadvantages:

Limited cooling and lubrication capacity.

Applications: Plastics, wood, aluminum.

Liquid Nitrogen and CO₂ (Cryogenic Fluids)

These coolants use extremely low temperatures to manage heat.

Advantages:

Exceptional cooling.

Improves tool life and surface finish in hard materials.

Environmentally safe.

Disadvantages:

High initial cost.

Requires special equipment.

Applications: Aerospace, medical-grade metals, titanium, nickel alloys.

4. Minimum Quantity Lubrication (MQL)

MQL involves applying a minimal amount of high-efficiency lubricant (usually a few ml/hr) as an aerosol directly to the cutting zone.

Advantages:

Drastic reduction in fluid usage and disposal costs.

Less environmental impact.

Cleaner machining environment.

Disadvantages:

Requires precise delivery systems.

Less effective in high-heat applications.

Applications: Precision machining, dry machining, green manufacturing initiatives.

How Cutting Fluids Improve Machining Quality

Surface Integrity

Cutting fluids reduce the temperature and friction between the cutting edge and the workpiece. This lowers the possibility of thermal cracks, plastic deformation, or chemical alteration in the material’s surface layers, leading to improved surface integrity.

Dimensional Accuracy

Excessive heat can cause thermal expansion in both the tool and workpiece. Cutting fluids regulate temperature, maintaining dimensional consistency and tight tolerances.

Reduced Tool Wear

Cutting fluids form a lubricating film that minimizes tool-workpiece interaction. This reduces abrasion, adhesion, and diffusion wear, increasing tool life and ensuring consistent machining quality.

Improved Chip Control

By aiding in chip breakage and evacuation, fluids prevent chip entanglement and surface damage, particularly in continuous chip-producing operations like turning or drilling soft metals.

Enhanced Speed and Feed Rates

With efficient cooling and lubrication, higher cutting speeds and feed rates can be used without compromising tool life or surface finish, increasing productivity.

Criteria for Selecting Cutting Fluids

The selection of a cutting fluid should be based on:

Material of the Workpiece: e.g., aluminum needs non-staining fluids, while stainless steel requires EP additives.

Type of Machining Operation: e.g., deep-hole drilling needs high-pressure coolant delivery.

Tool Material: Carbide, HSS, and coated tools interact differently with fluids.

Machining Parameters: High-speed applications demand high cooling capability.

Environmental Regulations: Compliance with REACH, OSHA, and local waste disposal laws.

Cost and Availability: Includes initial fluid cost, maintenance, filtration, and disposal.

Environmental and Health Concerns

Although cutting fluids provide performance benefits, they pose environmental and health challenges:

Skin Irritation: Prolonged exposure to cutting fluids may cause dermatitis or allergies.

Respiratory Issues: Mist from oil-based fluids can affect air quality in workshops.

Waste Disposal: Spent fluids are classified as hazardous waste in many regions and require costly disposal procedures.

Microbial Growth: Water-based fluids can become breeding grounds for bacteria and fungi.

Sustainability Measures:

Use of biodegradable fluids.

Adoption of MQL or dry machining.

Recycling and filtration systems.

Employee training on fluid handling and disposal.

Future Trends and Innovations

As manufacturing processes evolve toward greater efficiency, precision, and sustainability, cutting fluid technologies are undergoing significant transformation. Three major trends—smart fluids, green machining, and AI-driven coolant management—are shaping the future of machining by addressing traditional limitations in heat control, environmental impact, and fluid maintenance.

1. Smart Fluids and Nanotechnology

One of the most promising advancements in cutting fluids involves the use of nanotechnology to create nano-enhanced cutting fluids, often referred to as smart fluids. These are typically conventional fluids infused with nanoparticles such as aluminum oxide, copper oxide, carbon nanotubes, or graphene. The nanoparticles provide exceptional thermal conductivity and enhanced lubricating properties.

These nano-fluids significantly outperform traditional coolants by improving heat dissipation at the tool-workpiece interface, thereby reducing cutting temperatures. This thermal stability minimizes tool wear and deformation of the workpiece, enabling higher dimensional accuracy. Additionally, the improved lubrication lowers friction, which not only extends tool life but also enhances the surface finish of the machined part.

Smart fluids are also highly customizable, allowing manufacturers to tailor fluid properties for specific materials and machining conditions. While cost and safety concerns surrounding nanoparticle exposure remain areas of research, the performance gains offered by these advanced fluids are setting new standards in precision machining.

2. Green Machining and Eco-Friendly Fluids

Environmental regulations and corporate sustainability goals have driven a shift toward green machining practices. Traditional cutting fluids, especially oil-based types, pose challenges in terms of disposal, environmental pollution, and health hazards. In response, industries are increasingly adopting bio-based or plant-derived cutting fluids that are biodegradable, non-toxic, and less hazardous to workers.

These eco-friendly fluids, often made from vegetable oils or esters, offer excellent lubrication while minimizing the release of harmful substances. In many cases, they can match or exceed the performance of mineral oil-based fluids, especially in operations requiring high lubricity.

Alongside these fluids, techniques like dry machining and Minimum Quantity Lubrication (MQL) are gaining popularity. MQL involves applying a small, controlled amount of lubricant directly to the cutting zone, drastically reducing fluid consumption. This not only decreases operating costs but also eliminates the need for complex fluid disposal systems, making machining more sustainable and cleaner.

3. AI and IoT in Coolant Management

Smart manufacturing systems are incorporating Artificial Intelligence (AI) and Internet of Things (IoT) technologies to optimize coolant usage and maintenance. Sensors embedded in the machining system can now monitor key parameters such as fluid concentration, temperature, pH levels, and microbial contamination in real time.

Data collected from these sensors is analyzed using AI algorithms to predict when fluids need replenishment, filtration, or replacement—this is known as predictive maintenance. The benefits include reduced downtime, extended fluid life, and consistent machining quality. Moreover, real-time monitoring helps ensure compliance with environmental and safety regulations by maintaining optimal fluid conditions at all times.

Conclusion

Cutting fluids are indispensable in modern machining for achieving high performance, quality, and operational efficiency. By cooling, lubricating, and assisting in chip removal, they play a vital role in extending tool life, improving surface finish, and maintaining dimensional accuracy.

The choice of cutting fluid must be guided by the type of material, operation, and environmental considerations. With rising demands for sustainability and precision, the future of cutting fluids lies in smart, eco-friendly, and application-specific innovations.

Understanding the types and roles of cutting fluids not only enhances machining quality but also leads to safer, cleaner, and more cost-effective manufacturing practices.

Related posts:

- Machining and Types of Machining.

- 5-Axis Machining vs 3-Axis Machining – Essential Differences, Applications & Limitations

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses

- How to Read Machining Drawings: 11 Essential Tips for Beginner

- 8 Common Mistakes in Machining and How to Avoid Them