Introduction to Machining Tolerances

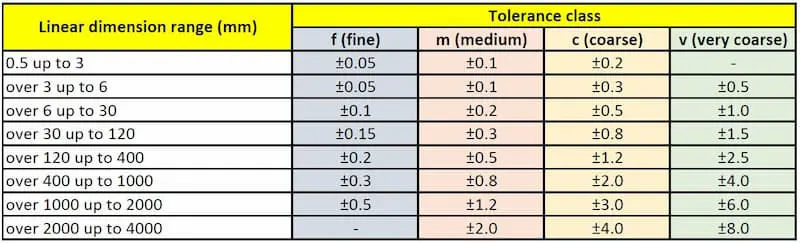

Machining tolerances are the specified limits of allowable variation in the dimensions of manufactured parts. No matter how precise a machine is, some variation is inevitable during production. Tolerances define the acceptable range within which these variations can occur without compromising the part’s fit, function, or performance. They are fundamental in ensuring that parts can be reliably produced, assembled, and operated in various engineering and manufacturing applications. Without clearly defined tolerances, components may fail to meet design requirements, leading to poor performance, increased costs, or safety issues.

What Are Machining Tolerances?

Machining tolerances define the permissible range of variation in the physical dimensions of manufactured parts. These tolerances indicate how much a particular measurement can differ from its nominal, or ideal, value while still ensuring that the part functions correctly within its intended application. In essence, tolerances set the boundaries within which a part is considered acceptable, balancing manufacturing feasibility with functional requirements.

For instance, consider a shaft designed to have a diameter of 10 millimeters. If the tolerance specified is ±0.05 millimeters, this means the shaft’s diameter can vary between 9.95 mm and 10.05 mm and still be deemed acceptable. The part must fall within this range to fit properly with mating components or to perform its intended mechanical function without causing issues such as excessive wear, poor fit, or mechanical failure.

Tolerances are critical in manufacturing because no process can produce parts with perfect accuracy every time. Material properties, machine precision, and environmental factors all influence the final dimensions. Therefore, specifying tolerances helps manufacturers maintain quality and functionality without requiring impossible precision. The tighter the tolerance, the more precise the manufacturing process must be, often increasing production costs and time. Conversely, looser tolerances allow for easier manufacturing but may reduce performance or interchangeability.

Types of Tolerances

Tolerances are essential in machining and manufacturing as they define the permissible variation in a part’s dimensions. Due to limitations in machine precision and material behavior, it is rarely possible to produce parts at an exact nominal size. Therefore, tolerances ensure that even with slight variations, the part will still fit, function, and perform as intended. There are three primary types of tolerances used in engineering and manufacturing: unilateral, bilateral, and limit tolerances.

1. Unilateral Tolerance

In unilateral tolerance, the variation from the nominal dimension is allowed in only one direction—either positive or negative, but not both. This means the actual size of the part can either be larger or smaller than the nominal value, but not both ways.

Example: A shaft with a nominal size of 25.00 mm and a tolerance of +0.10/-0.00 mm allows the actual size to range from 25.00 mm to 25.10 mm.

Applications: This type of tolerance is used when the part must not exceed a specific dimension, such as fitting into a hole or preventing interference in assemblies.

2. Bilateral Tolerance

Bilateral tolerance allows variation in both directions from the nominal size. The tolerance may be equal or unequal above and below the nominal dimension.

Example: A part specified as 40.00 mm ±0.05 mm can be manufactured anywhere between 39.95 mm and 40.05 mm.

Applications: Bilateral tolerances are commonly used in general machining practices where symmetry of allowable deviation is preferred and where slight deviations in either direction do not critically affect function.

3. Limit Tolerance

Limit tolerances specify the maximum and minimum permissible sizes directly, without stating the nominal dimension separately. This provides a clear range within which the actual dimension must fall.

Example: A hole specified with limits of 10.00 mm and 10.20 mm indicates that the diameter must be between these two values.

Applications: Often used in technical drawings and quality control to simplify inspection and avoid ambiguity during manufacturing.

Each type of tolerance serves a specific role depending on design requirements, functional constraints, and manufacturing capabilities. Choosing the right tolerance type helps balance precision, cost, and performance, ensuring that parts can be produced efficiently while still meeting quality standards.

Why Do Tolerances Matter?

Tolerances play a crucial role in engineering and manufacturing by defining acceptable variations in part dimensions. They ensure that components function as intended, are safe to use, and can be produced efficiently. Here are the key reasons why tolerances are so important:

1. Functionality and Fit

Many mechanical parts must fit together precisely to work properly. For example, a shaft must fit snugly into a bearing for smooth rotation without excessive play or friction. If the dimensions of either part are outside their specified tolerances, they may not fit correctly, leading to performance issues, wear, or mechanical failure.

2. Interchangeability

Tolerances ensure that parts can be produced consistently, even across different production runs or suppliers. This interchangeability means that components don’t need custom fitting and can be replaced or assembled with minimal variation. It’s especially vital in mass production, where maintaining uniformity saves time and labor.

3. Quality Control

Tolerances provide clear, measurable criteria to assess whether a part meets design specifications. This allows for effective inspection during and after manufacturing. By comparing actual measurements to tolerance limits, manufacturers can detect and reject out-of-spec parts early, reducing waste and improving overall quality.

4. Cost Efficiency

Tighter tolerances often require more advanced machining techniques, better tooling, and more thorough inspections, all of which increase production costs. By specifying tolerances that are only as tight as necessary for the part to function correctly, designers can reduce manufacturing time and cost without compromising quality or performance.

5. Safety and Reliability

In high-risk industries such as aerospace, automotive, or medical devices, precision is critical. Parts that deviate from tolerances can cause system failures, injuries, or worse. Strict adherence to tolerances ensures that critical components perform reliably under demanding conditions, protecting both users and equipment.

How Are Tolerances Specified?

In engineering design and manufacturing, precise communication is crucial to ensure that the final product functions as intended. One of the key aspects of this communication is the specification of tolerances on engineering drawings and technical documents. Tolerances define the allowable variation in part dimensions, which helps in maintaining the quality, functionality, and interchangeability of parts. Without clearly defined tolerances, manufacturers may produce parts that are either too loose or too tight, leading to performance issues, increased production costs, or even failure in assembly.

The process of tolerancing ensures that a part can be manufactured with a realistic level of precision and still perform its intended function. Properly specified tolerances balance the design requirements with manufacturing capabilities, ensuring that parts are neither over-engineered nor under-specified. This balance helps avoid unnecessary machining costs while guaranteeing the part will function as needed in its operational environment.

There are three primary methods for specifying tolerances in engineering: plus-minus notation, limit dimensions, and geometric dimensioning and tolerancing (GD&T). Each of these methods serves different purposes and is chosen based on the complexity and functional requirements of the part.

1. Plus-Minus Notation

Plus-minus notation is the most common and intuitive method for specifying tolerances. It involves stating a nominal dimension followed by an allowable deviation in both the positive and negative directions. This form of tolerance is simple to read, easy to apply, and well-understood by both designers and machinists.

Example:

A drawing might list a dimension as:

50 mm ± 0.1 mm

This means that the acceptable size for the feature can range from 49.9 mm to 50.1 mm. Any size within this range is acceptable, and the part will be considered within specification.

Use Case:

Plus-minus tolerancing is often used in general machining, fabrication, and assembly work where uniformity and simplicity are desirable. It works best for parts where the tolerance zone is symmetrical about the nominal size and when there is no critical functional requirement that demands tighter control in a specific direction.

For instance, shafts, holes, brackets, and other simple mechanical features that are not dependent on extremely tight fits or complex spatial relationships often use this method. It allows for quick interpretation during both production and inspection.

Despite its simplicity, this method has some limitations. In cases where the function of the part is directionally sensitive or where asymmetrical tolerance zones are required, plus-minus notation may not provide the necessary precision. Also, it does not convey information about the orientation, location, or relationship between features.

2. Limit Dimensions

Limit dimensions present another approach, where instead of using a nominal value with a tolerance, the acceptable dimensional range is explicitly given. In this format, the drawing lists the maximum and minimum permissible values for a dimension.

Example:

A part feature may be dimensioned as:

49.9 mm – 50.1 mm

This means the actual size of the part must fall within this range, inclusive. It removes the need to calculate the acceptable limits based on a plus-minus tolerance, thereby reducing the possibility of misinterpretation.

Use Case:

This method is especially popular in production environments and quality control. Because the allowable range is explicitly stated, it simplifies inspection processes. Inspectors can directly compare measurements against the stated limits without performing any calculations, which minimizes errors and improves efficiency.

Limit dimensions are commonly used in mass production and high-precision applications where consistency and clarity are essential. They are particularly useful when tolerances are tight and even small deviations can affect performance, such as in mating parts, press fits, and assemblies with moving components.

While limit dimensions offer clarity, they can become cumbersome for complex parts with many features. For such cases, geometric tolerancing often provides a better solution.

3. Geometric Dimensioning and Tolerancing (GD&T)

Geometric Dimensioning and Tolerancing (GD&T) is a more sophisticated system that uses a symbolic language to communicate not just the size of a feature, but its form, orientation, location, and relationship to other features. GD&T allows engineers to precisely define how a part must behave in its functional environment while providing flexibility in manufacturing methods.

Common Symbols in GD&T Include:

⌀ for diameter

⊥ for perpendicularity

⧄ for positional tolerance

These symbols are used in conjunction with feature control frames that specify the allowable variation for different geometric characteristics. For example, a positional tolerance may specify that a hole must be within a cylindrical tolerance zone of 0.1 mm in diameter, positioned relative to a datum reference frame.

Use Case:

GD&T is essential for complex or high-performance parts, particularly in industries such as aerospace, automotive, and precision instruments. It is particularly valuable when the functional performance of a part depends not just on the size of features, but also on their orientation, alignment, or spatial relationships.

For example, the alignment of a hole in relation to a shaft or the flatness of a sealing surface is critical in many assemblies. Using GD&T, designers can specify such requirements precisely and unambiguously.

Another advantage of GD&T is that it allows for greater manufacturing flexibility. By focusing on the functional requirements rather than rigid dimensions, manufacturers can choose different processes or setups that meet the specification, potentially reducing cost and time.

However, GD&T requires specialized knowledge to interpret and apply correctly. Both design engineers and manufacturing personnel must be trained in the standard (typically ASME Y14.5 or ISO 1101), and inspection equipment must be capable of verifying geometric tolerances accurately.

Choosing the Right Method

Each tolerancing method has its unique strengths and is suitable for different applications:

Plus-minus notation is best for simple parts where equal deviation is acceptable and where geometric relationships are not critical.

Limit dimensions provide clear and direct communication, ideal for high-volume production and when inspection simplicity is a priority.

GD&T is indispensable when functional performance depends on complex geometrical relationships between features, allowing for precise control and greater design intent communication.

In practice, these methods are often used together on the same drawing. For example, basic sizes might be given with plus-minus tolerances, while critical features might use GD&T for orientation or location control. The key is to match the tolerance method to the functional needs of the part and the capabilities of the manufacturing and inspection processes.

Conclusion

Machining tolerances are a fundamental aspect of modern manufacturing. They define the allowable variations in part dimensions and ensure that components function properly, fit together, and meet quality standards—without adding unnecessary cost. Whether through simple plus-minus notation, clearly defined limit dimensions, or the precision of GD&T, tolerances bridge the gap between design intent and real-world production. By understanding and applying tolerances effectively, engineers and manufacturers can produce high-quality parts that perform reliably in a wide range of applications.

Related posts:

- Machining and Types of Machining.

- 5-Axis Machining vs 3-Axis Machining – Essential Differences, Applications & Limitations

- Electrical Discharge Machining (EDM): Top 3 Types, Key Principles & Industries That Rely on It

- Laser Cutting vs. Waterjet Cutting: 7 Key Differences, Pros & Best Uses

- How to Read Machining Drawings: 11 Essential Tips for Beginner

- 8 Common Mistakes in Machining and How to Avoid Them