Forging, one of the oldest metalworking processes, has played a critical role in shaping the backbone of industrial manufacturing. Over the centuries, forging has evolved significantly, incorporating new materials, methods, and technological innovations. As industries increasingly demand high-strength, precision-engineered components with minimal waste, forging technology has responded with a suite of modern advancements. This essay explores the key trends currently shaping the forging landscape, including automation, digitalization, sustainability, hybrid processes, advanced materials, and quality assurance, among others.

Integration of Automation and Industry 4.0

The advent of Industry 4.0 has had a profound impact on forging technology. With automation and smart manufacturing at its core, Industry 4.0 promotes efficiency, precision, and consistency.

Key Innovations:

Robotics and Automation: Robotic arms are now integrated into forging lines to automate repetitive tasks such as billet loading, die handling, and product unloading. This has resulted in improved safety, higher throughput, and consistent quality.

CNC Integration: Computer Numerical Control (CNC) systems are employed in machining and die production, improving dimensional accuracy and repeatability.

Smart Sensors and IoT: Forging presses are now equipped with sensors that monitor temperature, pressure, and force. These sensors relay real-time data to cloud-based systems, enabling predictive analytics and process optimization.

Predictive Maintenance: Machine learning algorithms analyze data trends to predict equipment failures, minimizing downtime and maintenance costs.

Benefits:

Increased process reliability

Reduction in manual labor

Improved operational efficiency

Better product consistency

Simulation, Modelling, and Digital Twin Technology

One of the most transformative developments in modern forging technology is the use of digital tools for process modeling and simulation. Engineers can now predict and visualize how materials will behave under forging conditions before production begins.

Applications:

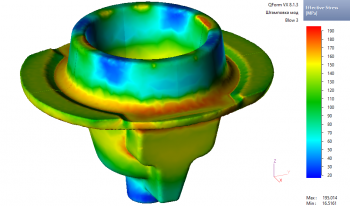

Finite Element Analysis (FEA): Simulates material flow, strain distribution, and thermal gradients during forging. This helps identify potential issues like die wear or material defects early in the design stage.

Digital Twins: A digital twin is a real-time digital replica of the forging process. It is used for monitoring performance, predicting outcomes, and improving efficiency.

Virtual Prototyping: Replaces physical prototypes, saving time and reducing costs associated with trial-and-error methods.

Key Software Tools:

DEFORM

QForm

Forge®

Simufact

Advantages:

Reduced development cycles

Improved product accuracy

Optimized die design

Decreased material waste

Emphasis on Sustainability and Green Forging

Sustainability has become a pivotal focus across all manufacturing sectors, and forging is no exception. Traditional forging processes are typically energy-intensive and can produce significant amounts of waste, making environmental impact a critical concern. In response, modern forging technologies are evolving to prioritize eco-friendly practices that reduce emissions, conserve energy, and minimize material loss while maintaining high product quality.

Sustainable Practices in Forging

Induction Heating:

Induction heating offers a more energy-efficient alternative to conventional gas-fired furnaces. It provides rapid, uniform heating directly to the workpiece, reducing energy consumption and minimizing oxidation-related defects. This method significantly lowers the carbon footprint of the heating process.Near-Net Shape Forging:

This approach aims to produce forged parts that are very close to their final dimensions, dramatically reducing the need for subsequent machining and the associated material waste. By minimizing excess material removal, near-net shape forging conserves valuable raw materials and lowers production costs.Eco-Friendly Lubricants:

Water-based and biodegradable lubricants are increasingly replacing traditional petroleum-based oils and greases. These eco-friendly alternatives reduce the release of harmful substances into the environment and improve workplace safety by minimizing toxic exposure.Energy Recovery Systems:

Some forging facilities have adopted waste heat recovery technologies that capture and reuse heat generated during forging. This recovered energy can be used to preheat materials or power other plant operations, thus enhancing overall energy efficiency.

Environmental Benefits

Significantly lower CO₂ emissions from reduced fossil fuel consumption and more efficient heating

Decreased scrap material through precision forging techniques and near-net shape manufacturing

Reduced energy consumption across the forging process, leading to cost savings and a smaller environmental footprint

Improved workplace safety due to cleaner processes and reduced use of hazardous materials

By adopting these sustainable forging practices, manufacturers are not only meeting regulatory requirements but also contributing to a greener, more responsible industrial future.

Advances in Materials and Metallurgical Engineering

The increasing demand for advanced performance in aerospace, defense, and automotive sectors has propelled significant innovations in materials and metallurgy within forging processes. These advancements enable the production of parts that meet stringent requirements for strength, durability, weight reduction, and corrosion resistance.

Material Innovations

Titanium and Superalloys:

Titanium alloys are highly favored in aerospace and medical applications because of their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. Superalloys, often based on nickel or cobalt, withstand extreme temperatures and mechanical stress, making them essential for jet engines, turbine components, and high-performance defense equipment.Aluminum Alloys:

Widely used in automotive manufacturing, aluminum alloys offer significant weight savings, which translates directly into improved fuel efficiency and reduced emissions. These alloys also provide excellent corrosion resistance and good machinability, making them ideal for lightweight chassis and structural components.Powder Metallurgy Forging:

This hybrid technique combines the advantages of powder metallurgy—such as fine microstructure and material homogeneity—with the shaping and strengthening benefits of forging. The result is components with high density, minimal porosity, and enhanced mechanical properties, suitable for critical applications.

Metallurgical Enhancements

Controlled Grain Flow:

During forging, grain structure is carefully manipulated to align with anticipated stress paths. This tailored grain orientation improves mechanical strength and significantly enhances fatigue resistance, prolonging the service life of components.Tailored Microstructures:

Post-forging heat treatments and thermomechanical processes are applied to optimize toughness, ductility, and hardness, allowing manufacturers to customize material properties based on specific application needs.

Benefits

More efficient use of high-value materials

Production of components with superior mechanical and fatigue performance

Expanded possibilities for complex and demanding applications

Enhanced resistance to wear, corrosion, and mechanical degradation

These material and metallurgical innovations are critical to meeting the evolving demands of cutting-edge industries.

Emergence of Hybrid Forging Processes

Hybrid forging processes blend the advantages of hot, warm, and cold forging techniques to enable the cost-effective production of complex, high-strength components. By carefully selecting and combining temperature ranges and deformation methods, manufacturers can optimize material properties, improve product quality, and reduce overall manufacturing costs.

Key Techniques in Hybrid Forging

Warm Forging:

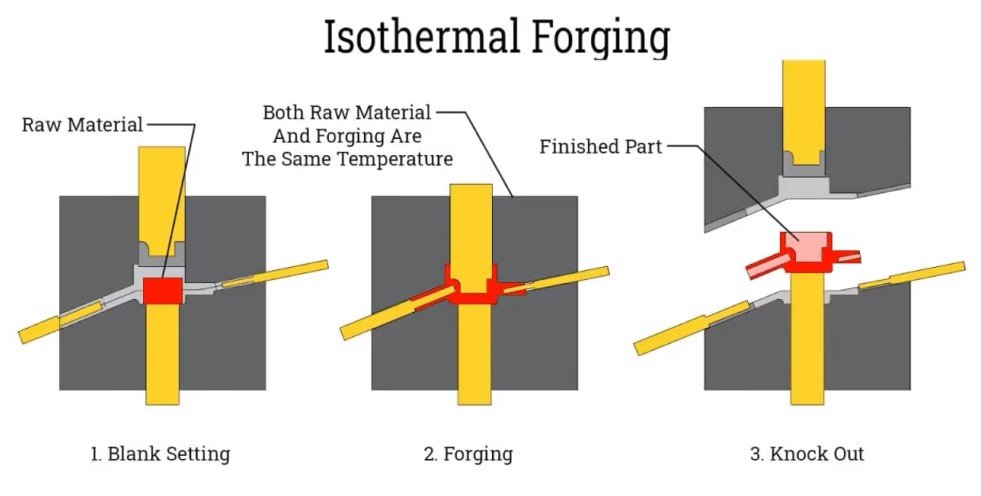

Conducted at intermediate temperatures, typically between 500°C and 900°C, warm forging strikes a balance between the dimensional accuracy of cold forging and the enhanced formability of hot forging. This technique reduces the forces required to shape the material while maintaining tight tolerances.Isothermal Forging:

In this process, both the die and the workpiece are kept at the same elevated temperature throughout forging. This ensures uniform deformation, minimizes thermal gradients, and results in superior surface finish and mechanical properties, making it ideal for high-performance aerospace and medical parts.Incremental Forging:

Incremental forging involves the gradual, stepwise deformation of the material. By applying smaller localized forces, it allows the manufacture of intricate shapes that would be difficult or impossible with traditional forging methods, while also reducing the risk of defects.Rotary and Radial Forging:

These specialized forging techniques are typically applied to long, cylindrical components like shafts and axles. Rotary and radial forging improve material utilization, reduce die wear, and enhance grain flow, leading to stronger, more durable parts.

Applications

Hybrid forging is widely used in the production of:

Gears with complex tooth profiles

High-strength engine components

Aerospace structural parts requiring excellent mechanical properties

Orthopedic implants demanding precision and biocompatibility

Advantages

Significantly reduced tool wear due to optimized forging temperatures

Improved surface finish and dimensional accuracy

Lower forming forces, reducing energy consumption

Greater control over final part dimensions and mechanical properties

By integrating these hybrid forging techniques, manufacturers can achieve enhanced product performance while maintaining cost efficiency and production flexibility.

Advanced Quality Control and Non-Destructive Testing (NDT)

Quality control in forging has evolved significantly with the integration of advanced monitoring systems and non-destructive evaluation techniques, ensuring that forged parts meet the highest standards of quality and performance. This is especially critical in industries such as aerospace, automotive, and medical devices, where component failure is not an option.

Quality Assurance Techniques

Modern forging employs a variety of non-destructive testing (NDT) methods to detect defects without damaging parts:

Ultrasonic Testing (UT): Uses high-frequency sound waves to identify internal cracks, voids, and inclusions, which are often invisible to the naked eye.

Magnetic Particle Inspection (MPI): Detects surface and near-surface defects in ferromagnetic materials, such as cracks caused by fatigue or stress.

Eddy Current Testing (ECT): Useful for finding surface cracks and conductivity changes in conductive metals, enabling rapid surface inspections.

X-Ray and CT Scanning: Offers detailed internal images, especially important for critical aerospace and medical components requiring zero internal flaws.

Inline Inspection Tools

Real-time monitoring has become integral to quality control:

Machine Vision Systems: High-resolution cameras combined with AI analyze surface finish, dimensions, and detect defects immediately as parts are produced.

Laser Scanners: Provide precise 3D dimensional verification, ensuring components adhere to tight tolerances.

Digital Quality Control

Digital tools help maintain consistent quality throughout production:

Statistical Process Control (SPC): Tracks and controls process variables to reduce variation.

Six Sigma and Lean Manufacturing: Aim to minimize defects and waste, improving overall efficiency.

Benefits

Advanced quality control techniques offer numerous advantages:

Increased reliability and safety of forged components.

Early defect detection reduces costly rework and scrap.

Ensures compliance with strict industry standards.

Enhances overall productivity and product consistency.

Together, these innovations are transforming forging into a highly precise, efficient, and dependable manufacturing process.

Customization and Flexible Production Systems

The increasing demand for low-volume, high-variety production has compelled forging facilities to shift from traditional mass production models toward flexible and agile manufacturing approaches. In a competitive landscape where customization, speed, and precision are paramount, modern forging operations are adopting new technologies and workflows that support dynamic production needs.

Modern Approaches in Flexible Forging

Modular Forging Systems

Designed for rapid tool changeovers, these systems allow manufacturers to switch between different product types with minimal downtime.

Ideal for short production runs and frequent product variation.

Digital Manufacturing Platforms

Enable real-time process monitoring, performance tracking, and remote system control.

Facilitate rapid design iterations and seamless data integration across departments.

Additive-Subtractive Hybrid Manufacturing

Merges the precision of 3D printing with the strength of forging.

Enables the creation of complex geometries that are otherwise difficult to forge directly, while enhancing material integrity.

Customer-Centric Manufacturing Strategies

Rapid Prototyping

Accelerates the development of custom dies and part samples, reducing time-to-market.

Supports low-risk experimentation with new product designs.

Collaborative Design

Clients engage in the design process using CAD/CAM tools and process simulations.

Ensures product specifications align closely with end-user requirements.

Key Benefits

Enhanced responsiveness to changing market demands

Reduced production lead times

Greater flexibility and customization capabilities

Improved competitiveness in specialized and niche markets

These flexible production strategies are redefining how forging companies meet diverse customer needs in today’s fast-evolving manufacturing environment.

Forging in Emerging and High-Tech Industries

The evolution of forging technology has significantly broadened its applicability, especially in cutting-edge sectors where performance, reliability, and precision are critical. With the advancement of materials, process control, and simulation tools, forged components are now essential in industries that operate under extreme conditions and require stringent quality standards.

Sectors Benefiting from Modern Forging

Aerospace

Forged components such as turbine discs, landing gear, shafts, and structural airframe parts demand exceptional strength-to-weight ratios and resistance to fatigue.

Precision forging ensures these components can endure high thermal and mechanical stresses while maintaining structural integrity.

Electric Vehicles (EVs)

Forging plays a key role in producing robust, lightweight parts such as motor housings, battery enclosures, and suspension components.

Lightweight forged parts contribute to extended battery range and improved vehicle efficiency.

Medical Devices

High-precision forged surgical instruments and orthopedic implants require biocompatibility, tight dimensional control, and excellent corrosion resistance.

Titanium and stainless steel are commonly forged to produce safe, long-lasting medical solutions.

Defense and Space

Forged high-performance alloys are used in missiles, rocket engines, and armored vehicle parts due to their ability to withstand extreme environments and mechanical loads.

Enhanced material properties provide durability and performance in mission-critical applications.

Strategic Importance

High reliability under extreme conditions

Compliance with strict international and safety standards

Lightweight and compact component design

Extended service life and reduced maintenance needs

These attributes make forging an indispensable manufacturing solution across high-tech, safety-critical industries.

Workforce Transformation and Skill Development

As forging technology evolves and integrates increasingly sophisticated systems, the demand for a highly skilled workforce is growing rapidly. Operators and technicians are now required to possess not only traditional mechanical expertise but also a strong understanding of digital tools, automation, and data-driven manufacturing environments. This transformation is reshaping workforce requirements across the industry.

Workforce Trends

Training in Mechatronics and Automation

Employees must be proficient in both mechanical components and electronic control systems.

Understanding software interfaces, programmable logic controllers (PLCs), and robotic systems is becoming essential.

Upskilling and Reskilling Programs

Ongoing training in advanced tools like CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and FEA (Finite Element Analysis).

Knowledge of data analytics and IoT applications is increasingly important for monitoring and optimizing processes.

Collaboration with Academic and Technical Institutions

Joint initiatives to develop customized training programs tailored to modern forging operations.

Internships, apprenticeships, and certification programs are helping to bridge the gap between education and industry needs.

Benefits of Workforce Development

Reduced Operational Errors : A well-trained workforce leads to fewer mistakes and higher process reliability.

Improved Job Satisfaction and Safety : Skilled workers are more confident and better equipped to manage complex machinery safely.

Increased Innovation : Educated employees contribute to process improvements and technological advancement.

Enhanced Talent Retention : Continuous development opportunities improve employee engagement and reduce turnover.

Investing in workforce development is essential for forging companies aiming to stay competitive in the era of advanced manufacturing.

Future Outlook and Challenges

Despite remarkable progress, forging technology still faces several pressing challenges that could limit its broader adoption and growth potential. Among the foremost issues is the high capital investment required for advanced forging equipment, automation systems, and digital infrastructure. This poses a significant barrier for small and mid-sized enterprises. Moreover, supply chain disruptions—driven by geopolitical tensions, transportation bottlenecks, and raw material shortages—have impacted delivery timelines and production efficiency. Additionally, manufacturers must navigate increasing regulatory pressures concerning emissions, energy use, and worker safety, prompting the need for continuous upgrades and compliance strategies.

Anticipated Developments

AI-Powered Process Control

Real-time monitoring of forging conditions (e.g., temperature, force)

Automated defect prediction and correction

Enhanced decision-making with minimal human intervention

Sustainable Forging Plants

Use of renewable energy (e.g., solar, wind) to power forging operations

Heat recovery systems to reduce energy waste

Transition to zero-emission heating and lubrication processes

Forging-as-a-Service (FaaS)

Cloud-based platforms for remote job scheduling and process control

On-demand access to forging capacity for smaller manufacturers

Lower upfront costs and increased operational flexibility

Ongoing Challenges

High Initial Investment : Cost of smart machinery, simulation tools, and IoT infrastructure

Technological Obsolescence : Rapid innovation rendering older systems outdated

Integration of Legacy Systems : Difficulty merging traditional equipment with modern digital tools

Training and Retention of Skilled Labor : Shortage of workers trained in both mechanical and digital disciplines

Addressing these challenges will be essential for the forging industry to fully realize its technological potential.

Conclusion

Modern forging technology is undergoing a transformative phase, driven by digitalization, material science advancements, sustainability imperatives, and the demands of high-tech industries. From robotic automation and digital twins to hybrid forging methods and eco-friendly practices, the forging industry is embracing innovation at every level. These trends are not only enhancing product quality and manufacturing efficiency but are also paving the way for more sustainable and adaptable manufacturing environments. As global competition intensifies and market requirements become more dynamic, staying at the forefront of these forging trends will be key to long-term success and relevance in the industrial manufacturing landscape.