As we step further into the 21st century, mechanical engineering continues to evolve at an unprecedented pace, driven by advances in technology and materials science. The year 2025 marks a milestone where cutting-edge innovations are not only transforming traditional mechanical systems but also redefining how industries operate—boosting efficiency, sustainability, and human capability. From smart materials and AI-driven design to breakthroughs in robotics and quantum computing, these mechanical innovations are shaping the future of manufacturing, aerospace, healthcare, and beyond. In this overview, we explore the most impactful mechanical engineering breakthroughs set to revolutionize the world in 2025.

1. Smart Materials and Self-Healing Systems

Smart materials and self-healing systems are transforming the way products are designed and built. These materials have a special ability: they can respond to changes in their environment, such as shifts in temperature, pressure, or stress. This ability allows them to adapt, heal, or even generate energy, making products more durable, efficient, and smarter.

Two common types of smart materials are shape-memory alloys (SMAs) and piezoelectric materials. Shape-memory alloys can “remember” their original shape. When they are bent or deformed, they can return to their original form when heated to a certain temperature. This makes them useful in many fields. For example, in aerospace, SMAs are used to create wings that change shape during flight to improve performance. They can also fix minor damages automatically, reducing the need for repairs.

Piezoelectric materials work differently. When they experience mechanical stress—like pressure or vibrations—they produce electrical energy. Conversely, applying an electric field can cause these materials to change shape slightly. This makes piezoelectric materials perfect for creating devices that harvest energy from motion, such as sensors or wearable technology. These devices can operate without batteries, increasing their lifespan and reducing waste.

One of the most exciting developments with smart materials is self-healing systems. These materials can detect damage, such as cracks or scratches, and repair themselves without human help. For example, some coatings contain tiny capsules filled with healing agents. When the coating is damaged, these capsules break open and release the agent, which fills the cracks and restores the surface. This technology is especially valuable in industries like robotics and aerospace, where equipment is exposed to tough conditions and repairs can be expensive or difficult.

Overall, smart materials and self-healing systems are making products stronger, longer-lasting, and more efficient. They reduce maintenance costs and improve safety by allowing materials to adapt and repair themselves. As a result, these technologies are changing the future of design across many industries.

2. Digital Twin Technology

Digital twin technology is changing how engineers design, monitor, and maintain complex systems. A digital twin is a virtual copy of a physical object or system. It replicates every detail of the real-world counterpart, allowing engineers to see how it behaves without being physically present. This means they can simulate, predict, and improve performance in real-time.

One of the biggest advantages of digital twins is their ability to provide a constant flow of data from the physical system to the virtual model. Sensors placed on machines, vehicles, or buildings collect information like temperature, pressure, and movement. This data is sent to the digital twin, which updates in real-time. Engineers can then analyze this information to understand how the system is performing and spot any potential problems early on.

Digital twins are especially useful in industries such as aerospace and automotive. In aerospace, for example, a digital twin of an aircraft engine can simulate how it will respond under different conditions. This helps engineers optimize the design for better fuel efficiency and safety. It also allows for predictive maintenance, meaning that potential failures can be detected before they happen. This reduces downtime and lowers repair costs.

Similarly, in the automotive industry, digital twins help in designing vehicles that are safer and more efficient. Engineers can test new parts virtually, speeding up the development process and reducing the need for physical prototypes. They also use digital twins to monitor cars in real-time, improving reliability and customer experience.

Beyond design and maintenance, digital twins support better decision-making. Because the virtual model mirrors the physical system exactly, companies can try out different scenarios and see the results without any risk. This leads to smarter investments and improved overall performance.

In summary, digital twin technology bridges the gap between the physical and digital worlds. It allows engineers to simulate, predict, and optimize systems more effectively. This leads to improved safety, efficiency, and cost savings, making it a powerful tool in many modern industries.

3. Artificial Intelligence in Design and Manufacturing

Artificial Intelligence (AI) is transforming design and manufacturing, making processes smarter, faster, and more efficient. AI-driven tools are now helping engineers and manufacturers in many ways, from predicting failures to improving designs and automating routine tasks.

One important use of AI is in mechanical design. AI algorithms can analyze large amounts of data from previous projects and real-world tests to predict where and when a part might fail. This helps designers find potential weaknesses early, even before physical prototypes are made. By identifying design flaws early, engineers can improve safety and reliability while saving time and money.

AI also automates repetitive and time-consuming tasks in the design process. For example, generating multiple design variations or running simulations can be done much faster with AI tools, freeing engineers to focus on creative and complex problem-solving. This speeds up the entire design cycle and helps bring products to market quicker.

In manufacturing, AI is used to optimize production lines and improve precision. Machine learning algorithms analyze data from machines and sensors to identify inefficiencies or errors. By continuously learning from this data, AI can adjust machine settings in real-time to increase accuracy and reduce waste. This not only lowers costs but also improves product quality.

AI-powered predictive maintenance is another key benefit. By monitoring equipment continuously, AI can predict when machines need servicing before they break down. This reduces unexpected downtime and costly repairs, keeping production running smoothly.

Overall, AI in design and manufacturing leads to smarter decisions and better outcomes. It enhances precision, reduces errors, speeds up workflows, and cuts costs. As AI technology advances, it will become an even more essential tool for engineers and manufacturers aiming to innovate and stay competitive.

In summary, AI is revolutionizing how products are designed and made by making processes more intelligent and efficient across the board.

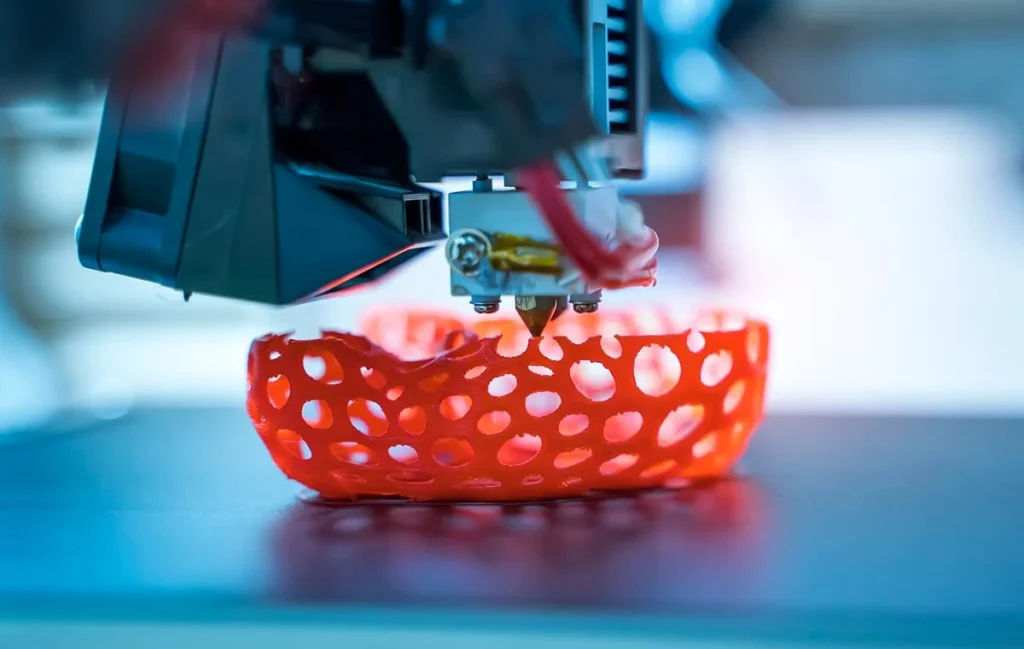

4. Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is changing the way products are made. Unlike traditional manufacturing, which often involves cutting away or molding materials, 3D printing builds objects layer by layer. This allows for the creation of complex shapes that are difficult or impossible to make using conventional methods.

One major benefit of 3D printing is its ability to produce lightweight components without wasting much material. Since the process adds material only where it is needed, it reduces scrap and lowers costs. This efficiency makes 3D printing a more sustainable option for manufacturing.

Industries like aerospace, healthcare, and automotive are taking full advantage of these benefits. In aerospace, for example, 3D printing is used to create parts that are both strong and lightweight, helping to improve fuel efficiency. These parts can have intricate internal structures that reduce weight without sacrificing strength—something that traditional manufacturing struggles to achieve.

In healthcare, 3D printing enables the production of customized implants, prosthetics, and surgical tools tailored specifically to individual patients. This personalization improves comfort and performance while speeding up the production process.

The automotive industry uses 3D printing for rapid prototyping—creating quick and affordable models to test new designs before full-scale manufacturing. This speeds up development cycles and allows engineers to make improvements early. Additionally, 3D printing is used to manufacture custom or low-volume parts that would be too expensive to produce using traditional methods.

Another advantage of 3D printing is its flexibility. Designers can easily modify digital models and print new versions quickly, supporting innovation and customization. This adaptability is particularly valuable in industries where demands and technologies are constantly evolving.

In summary, additive manufacturing is revolutionizing production by enabling the creation of complex, lightweight, and customized components with less waste. Its growing use across various industries highlights its importance in modern manufacturing and product development.

5. Soft Robotics

Soft robotics is a new and exciting field inspired by the flexible and gentle movements of living organisms. Unlike traditional robots, which are often rigid and made from hard materials, soft robots use flexible, stretchable materials. This allows them to perform delicate tasks with great precision and care, making them ideal for handling fragile objects or working in complex environments.

One key advantage of soft robots is their ability to adapt their shape and movements to their surroundings. Because they are made of soft materials, they can squeeze, bend, and stretch without damaging themselves or the objects they interact with. This makes them especially useful in areas where gentle handling is crucial, such as in food processing, agriculture, and biomedical fields.

Recent advances in soft robotics have focused on improving speed and strength. Engineers have developed soft robots with joints that can move quickly and powerfully, while still maintaining flexibility. This combination of agility and softness opens up new possibilities for applications that were previously difficult or impossible for traditional robots.

For example, in minimally invasive surgery, soft robots can navigate through tight and sensitive spaces inside the human body without causing harm. Their gentle movements help surgeons perform complex procedures with greater accuracy and less risk to patients. This technology promises to improve recovery times and surgical outcomes.

Soft robotics is also making an impact in manufacturing and assembly lines. These robots can handle delicate parts, such as electronics or small components, with precision, reducing the risk of damage during production. Their flexibility also allows them to work alongside humans safely, making them valuable for collaborative tasks.

In summary, soft robotics combines the flexibility and sensitivity of natural organisms with advanced engineering to create robots capable of delicate, precise, and powerful movements. As this technology continues to develop, it will play an increasingly important role in healthcare, manufacturing, and many other fields.

6. Quantum Computing in Mechanical Design

Quantum computing is beginning to revolutionize mechanical engineering by offering powerful new ways to solve complex problems. Unlike traditional computers, which use bits as units of information, quantum computers use quantum bits, or qubits. These qubits can represent multiple states at once thanks to a property called superposition. This allows quantum computers to process vast amounts of data and perform many calculations simultaneously, far beyond the capability of classical computers.

One area where quantum computing is making a big impact is in mechanical design. Engineers often need to run complex simulations and analyze materials to create better products. These tasks require heavy computational power because they involve many variables and interactions. Quantum computing provides this power, enabling faster and more accurate simulations that were previously too time-consuming or impossible to perform.

For example, in material analysis, quantum computers can model how atoms and molecules behave in different materials. This helps engineers discover new materials with improved strength, flexibility, or heat resistance. By understanding materials at the quantum level, designers can create components that perform better and last longer.

Quantum computing also improves design optimization. Traditional methods often rely on trial and error, testing many possible designs to find the best one. With quantum algorithms, engineers can analyze multiple design options simultaneously, quickly identifying the most efficient and effective solutions. This leads to better mechanical systems that use less material, consume less energy, and perform more reliably.

Additionally, quantum computing supports solving complex engineering problems, such as fluid dynamics or thermal management, that involve countless interacting factors. Faster and more detailed simulations allow for innovative designs in aerospace, automotive, robotics, and other fields.

In summary, quantum computing is enhancing mechanical design by providing unmatched computational power for simulations, material analysis, and problem-solving. As this technology advances, it promises to transform how engineers design and optimize mechanical systems, leading to smarter, stronger, and more efficient products.

7. Exoskeletons for Enhanced Human Capability

Wearable exoskeletons are emerging as powerful tools to boost human strength and reduce injuries in the workplace. These devices are designed to be worn like suits or braces, supporting the body during physical tasks such as heavy lifting, repetitive movements, or rehabilitation exercises. By combining advanced mechanical design with human-focused engineering, exoskeletons improve both performance and safety across many industries.

One of the main benefits of exoskeletons is their ability to reduce strain on muscles and joints. Workers who regularly lift heavy objects or perform physically demanding tasks are at high risk of injuries like back pain or repetitive strain injuries. Exoskeletons help by sharing the load, supporting the body’s natural movements, and minimizing fatigue. This support reduces the chance of injury and allows workers to perform tasks more comfortably and efficiently.

Exoskeletons are also valuable in rehabilitation. People recovering from injuries or surgeries can use these devices to regain strength and mobility. The exoskeleton provides assistance and guidance during exercises, helping patients move safely and rebuild muscle control. This technology is improving recovery outcomes and speeding up the healing process.

Industries such as manufacturing, construction, logistics, and healthcare are increasingly adopting exoskeleton technology. In factories, workers can wear exoskeletons to lift heavy tools or materials with less effort. On construction sites, exoskeletons help reduce physical strain during long shifts. Healthcare workers benefit from exoskeletons by reducing injury risks when moving patients or performing repetitive tasks.

Designing exoskeletons requires a careful balance between mechanical strength and comfort. Engineers focus on creating lightweight, flexible devices that move naturally with the wearer while providing the necessary support. Sensors and motors are often integrated to enhance movement and adapt assistance based on the user’s needs.

In summary, wearable exoskeletons are transforming how people work and recover from injury. By enhancing human capability and reducing physical strain, these devices promote safer workplaces and faster rehabilitation, making them valuable tools across a wide range of fields.

Conclusion

In summary, the mechanical innovations of 2025 highlight a transformative era where technology and engineering merge to redefine industry standards and human capabilities. Advances such as smart materials and self-healing systems are improving durability and efficiency, while digital twin technology offers unprecedented real-time insights for optimizing performance and maintenance. The integration of artificial intelligence in design and manufacturing streamlines processes and reduces errors, making production smarter and more cost-effective. Meanwhile, additive manufacturing continues to revolutionize how complex parts are created, enabling rapid prototyping and customization that were previously unimaginable.

Soft robotics are expanding the possibilities of delicate and precise operations, particularly in healthcare and manufacturing, while quantum computing promises to accelerate simulation and problem-solving at scales never before possible. Additionally, exoskeleton technology is enhancing human strength and safety in industrial and medical settings, reflecting a growing emphasis on human-machine collaboration.

Together, these innovations are driving a new wave of sustainable and efficient engineering solutions, helping industries meet the challenges of today and tomorrow. As these technologies mature and integrate, they will not only redefine mechanical engineering but also profoundly impact society by improving productivity, safety, and environmental responsibility. Staying abreast of these trends will be crucial for engineers and organizations aiming to remain competitive and innovative in the rapidly evolving landscape of 2025 and beyond.